Gluconobacter oxydans and method for preparing ketoxylose using the same

A technology of Gluconobacter oxidans and xylulose, applied in the fields of fermentation engineering and enzyme engineering, can solve problems such as increased production costs, separation and purification of unfavorable products, and difficulties in downstream processes

- Summary

- Abstract

- Description

- Claims

- Application Information

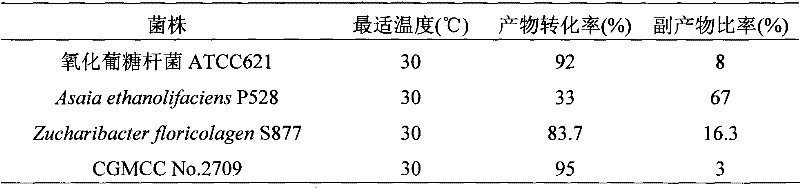

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Incline medium: glucose 30g / L, yeast extract 10g / L, beef extract 5g / L, agar 20g / L.

[0044] Shake flask medium: glucose 30g / L, yeast extract 25g / L, beef extract 5g / L, D-arabitol 10g / L, KH 2 PO 4 5g / L.

[0045] Cultivate Staphylococcus oxidans CGMCC No.2709 on a slant medium at 30°C for 24 hours, then put a ring of this bacteria in the shake flask medium, cultivate it at 30°C for 10 hours, and the shake flask rotates at a speed of 200r / min. The content of D-ara is 20g / L, and the enzyme production is 2.5~5.0U / mL. It is transformed by free cells. Weigh 1g of wet cells after centrifugation and add them to 10mL of 30g / L D-ara solution (the amount of cells added is calculated as per 100g of cells transformed 1L 30g / L D-ara solution), under the condition of 30°C, stir and shake in a shaker flask (rotating speed 120r / min) to convert and produce D-xylulose, the reaction time is 9h, and the conversion rate of the substrate is measured after the reaction is terminated and prod...

Embodiment 2

[0047] With 30g / L maltose as the carbon source, 20g / L yeast extract, and 10g / L bean cake powder as the nitrogen source, the other components of the medium and the cell culture conditions are the same as in Example 1, and a 1.5% sodium alginate colloid solution is prepared, and the physiological After mixing the bacterial suspension prepared with saline evenly, add 8% diatomaceous earth for adsorption, and drop 2% CaCl with a syringe 2 Solidify in the solution to make spherical immobilized cells with a diameter of about 3-4mm, and put them in a refrigerator at 4°C for several hours, then pour off the supernatant, wash twice with distilled water, and replace 1g of the centrifuged wet cells with seaweed 5 g of immobilized cells were obtained by embedding in sodium phosphate, and transformed into 10 mL of 50 g / L D-arabitol solution (rotational speed 200 r / min) in a shake flask at 30 ° C. The transformation time of each batch was 13 h, and 30 batches were transformed. times, the av...

Embodiment 3

[0049] Glucose 225g, yeast extract 112.5g, beef extract 22.5g, D-arabitol 45g, KH 2 PO 4 22.5g, pH 5.0, dilute to 4.5L with water, make culture medium, put into 7.5L stirring fermenter, steam sterilize at 121℃ for 15min. Prepare seed medium: glucose 30g / L, yeast extract 10g / L, beef extract 5g / L. Put Gluconobacter oxydans CGMCCNo.2709 in the seed medium one by one, and culture it at 30°C for 8 hours to obtain the seed liquid. Put the seed liquid into the cooled fermentation medium according to the inoculation amount of 3% of the volume of the fermentation liquid, and cultivate it at 30°C. (Ventilation 0.7vvm, stirring speed 600r / min) 48h. The fermented liquid is subjected to bacterial filtration treatment in an ultrafilter, and the molecular weight cut-off of the ultrafiltration membrane is 10 6 Da, the operating pressure is 0.2MPa, the temperature is controlled at 50°C, and the membrane surface velocity is 4m / s. After immobilizing the 100g bacterium obtained by interceptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com