Profiled bar freezing wall foundation ditch combined enclosure method and its structure

A profiled steel and wall foundation technology, which is applied in the combined enclosure method and structure field of a foundation pit using profiled steel freezing walls, and achieves the effects of high strength, strong adaptability and convenient repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

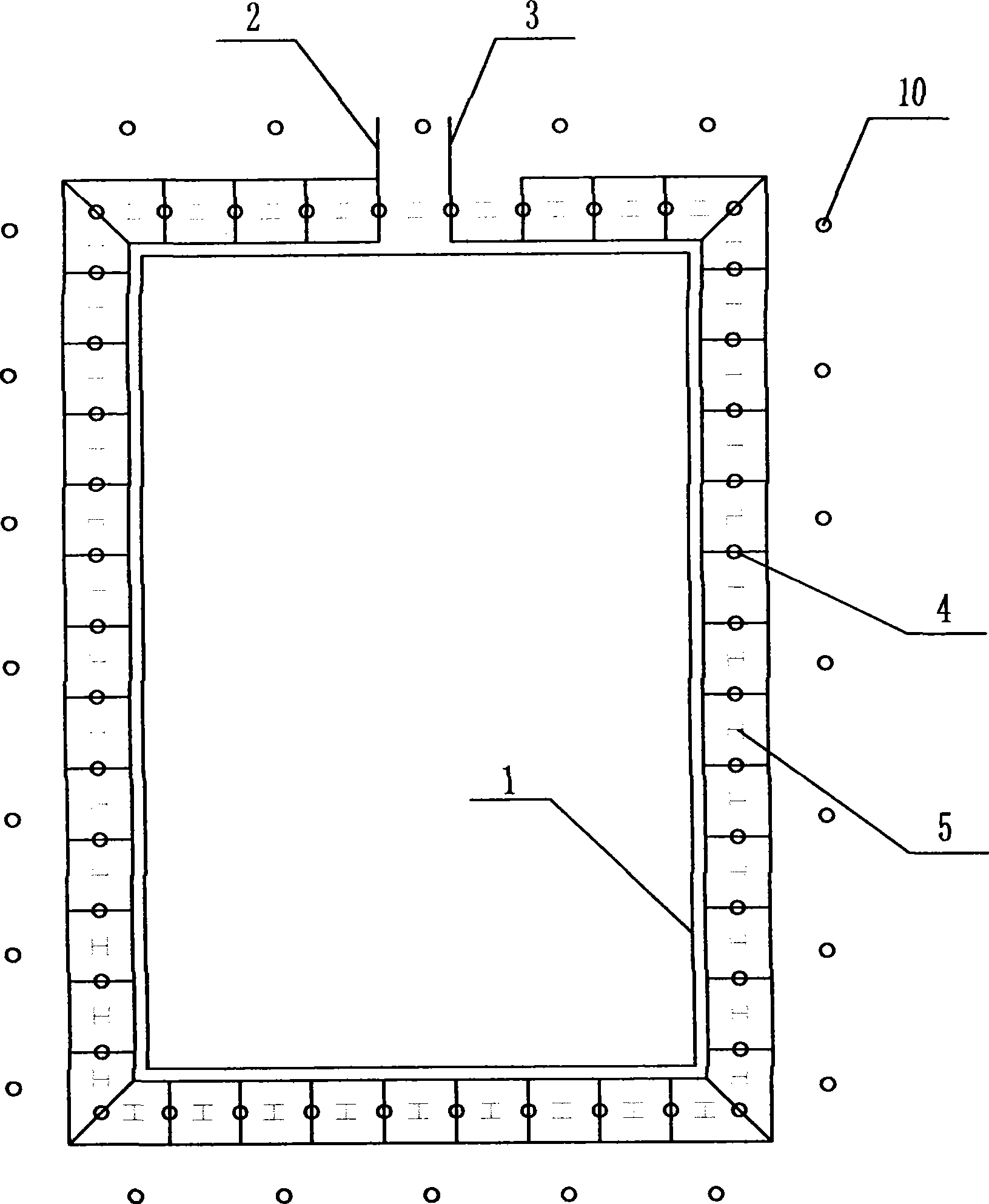

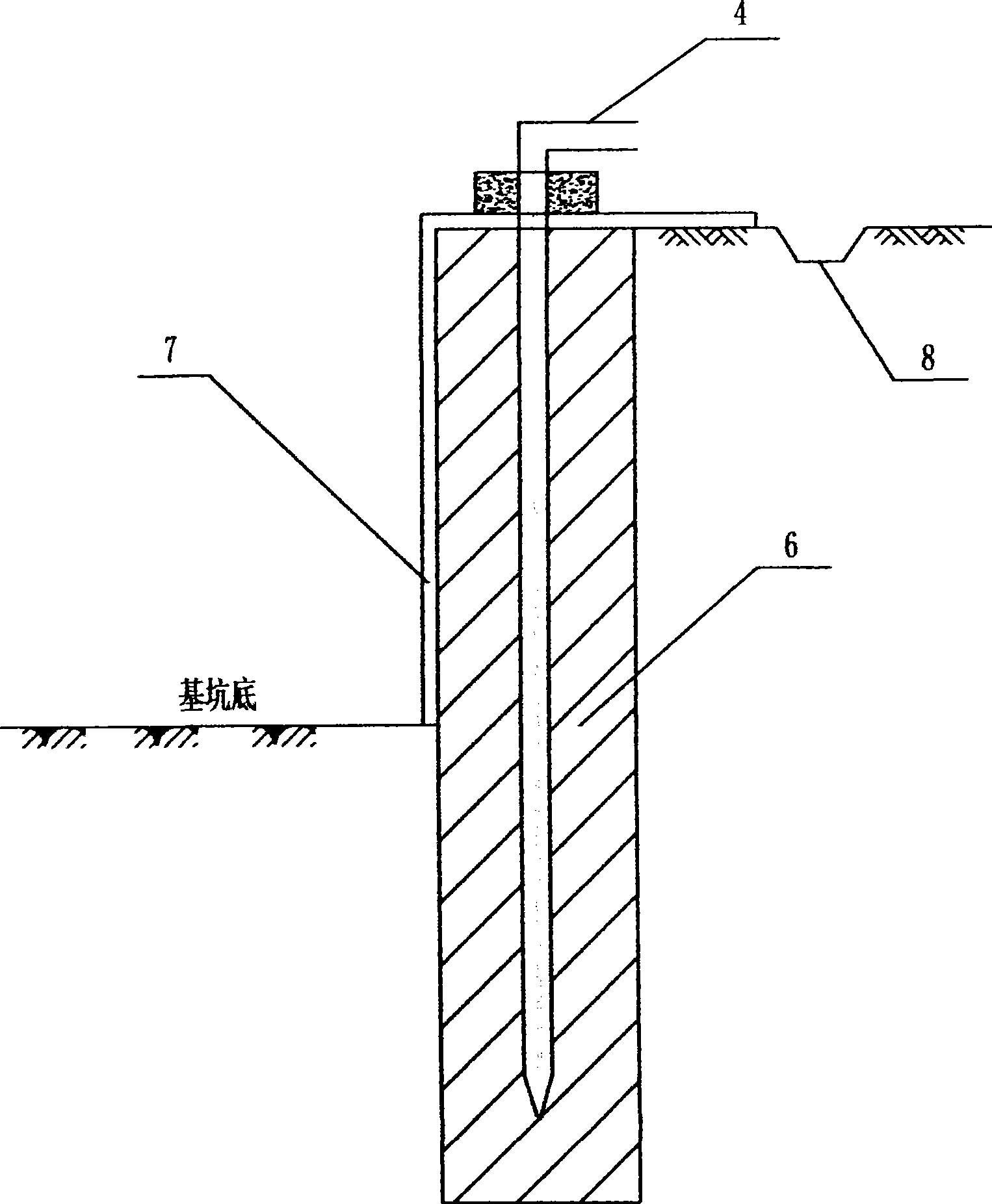

[0050] Such as figure 2 , image 3 , Figure 4 As shown, the steel frozen wall foundation pit combined enclosure structure of the present invention includes a frozen wall 6, and the frozen pipe 4 is embedded in the frozen wall 6, and the frozen pipe 4 is connected to the liquid inlet pipe 2 and the liquid return pipe 3 respectively, and the shaped steel 5 adopts Interval plug-in type, continuous plug-in type or combined plug-in type are pre-inserted into the frozen wall 6 , an insulation layer 7 is also provided outside the frozen wall 6 , and pressure relief holes 10 are arranged around the frozen wall 6 .

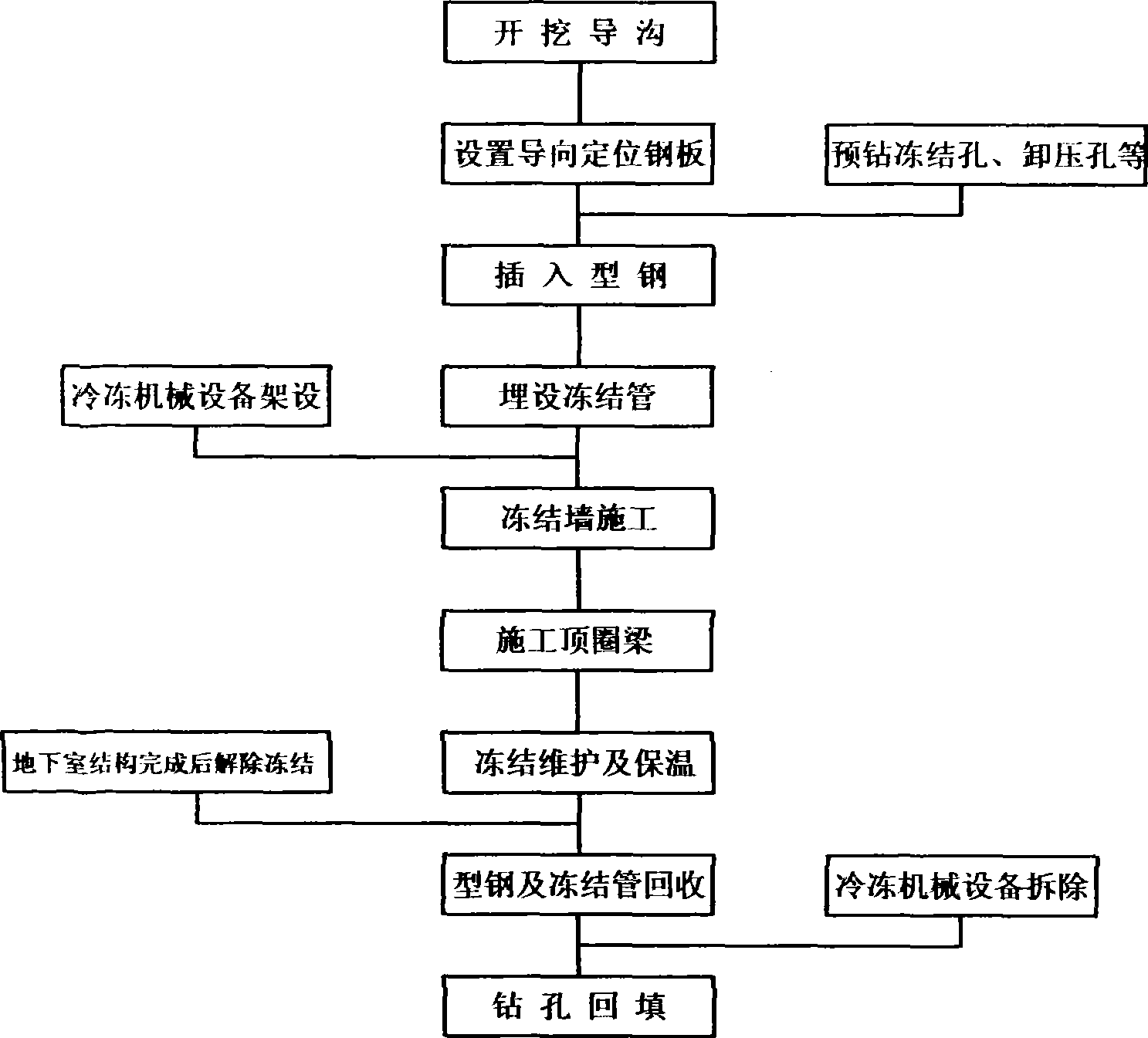

[0051] combine figure 1 Shown, the section steel freezing wall foundation pit combined enclosure method of the present invention comprises the following steps:

[0052] (1) Digging guide trench

[0053] According to the excavation limit set by the construction drawings, determine the construction of the frozen wall and the insertion position of the section steel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com