Off-course driving device of wind-driven generator

A technology of yaw driving device and wind power generator, which is applied in the control of wind power generators, wind power generators, wind power generation, etc. It can solve the problems of complex reliability of the driving mechanism, large resistance of yaw driving, and reduced reliability, etc., so as to avoid Effects of broken pipes, improved power generation efficiency, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

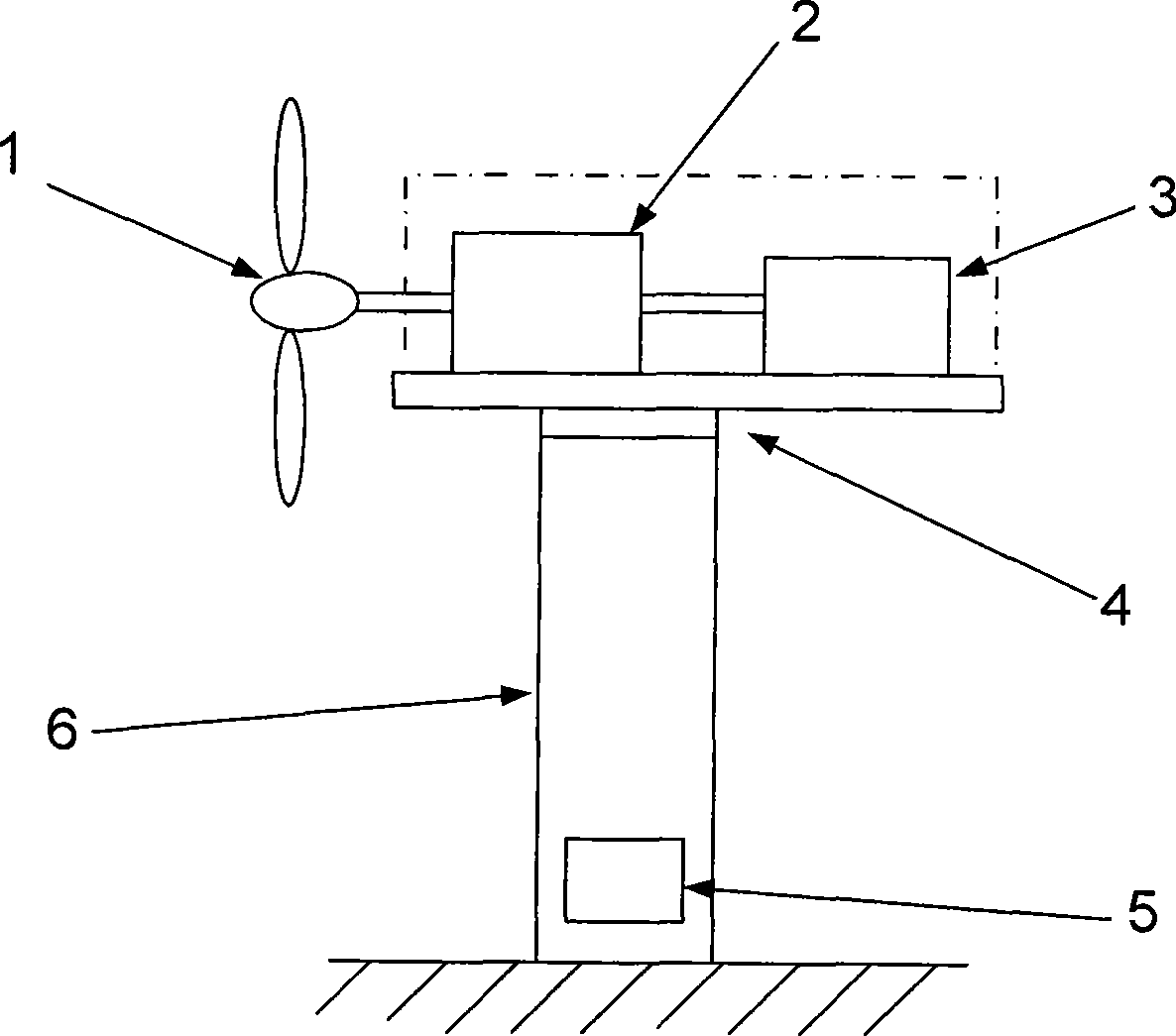

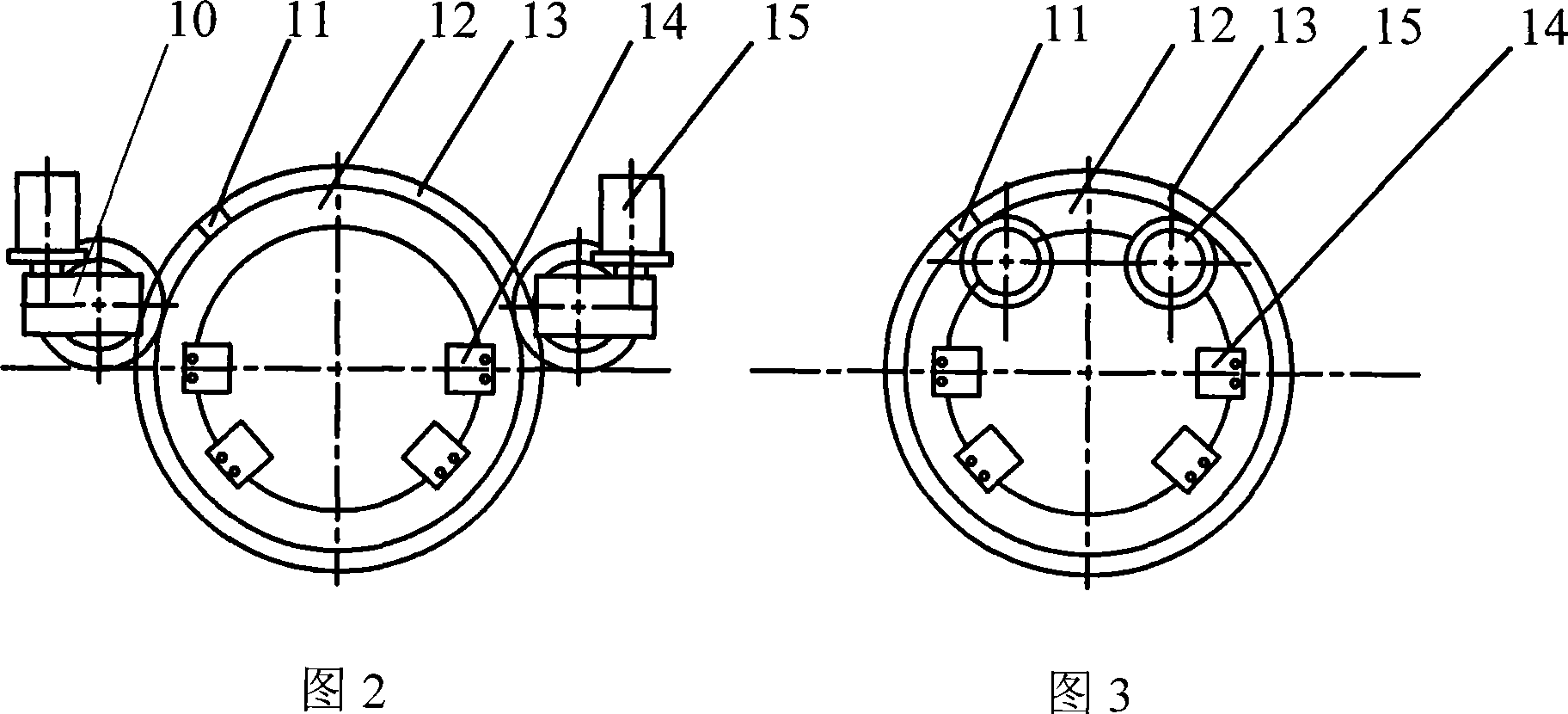

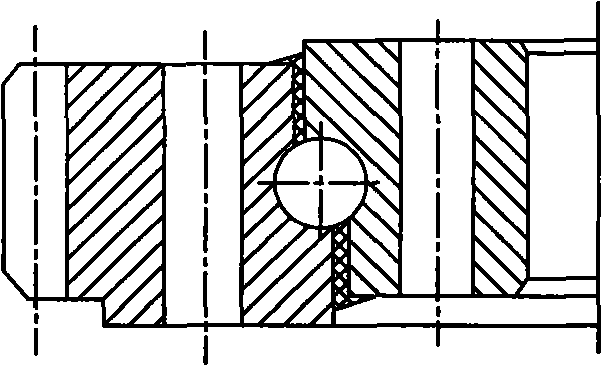

[0013] Specific implementation mode one: combine Figure 6 To illustrate this embodiment, the yaw driving device of the wind power generator is composed of a wind vane, a direct-drive electro-hydraulic servo low-speed high-torque hydraulic motor, a yaw chainring 13, and a yaw braking device; the wind vane sends an electric signal to change the wind direction In the processor of the control system, after comparison, the processor sends a clockwise or counterclockwise yaw command to the direct-drive electro-hydraulic servo low-speed high-torque hydraulic motor, and the output shaft of the direct-drive electro-hydraulic servo low-speed high-torque hydraulic motor The installed drive gear meshes directly with the yaw chainring 13; the locking part of the yaw braking device is directly installed on the output shaft of the direct-drive electro-hydraulic servo low-speed high-torque hydraulic motor, and the direct-drive electro-hydraulic servo low-speed high-torque hydraulic motor The...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 6Describe this embodiment, the difference between this embodiment and the specific embodiment is that the yaw braking device is composed of a proportional relief valve 31, a hydraulic source 32 and a yaw brake 33; the oil inlet of the proportional relief valve 31 and the hydraulic source The oil outlet of 32 is connected to the control oil port of yaw brake 33, the oil outlet of proportional relief valve 31 and the oil inlet of hydraulic source 32 are respectively connected to two oil tanks; yaw brake 33 is mechanically locked Clutch; the locking part of the yaw brake 33 is directly installed on the 26 shafts of the low-speed high-torque hydraulic motor, and yaw braking and yaw damping are realized by tightening and loosening the 26 shafts of the low-speed high-torque hydraulic motor. The yaw brake 33 has a hydraulic source independent of the yaw drive motor, which can ensure that the brake can act independently of t...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 6 Describe this embodiment, the difference between this embodiment and the specific embodiment 1 or 2 is that the oil supply valve 24 is composed of two hydraulic control check valves, and the two hydraulic control check valves are respectively the first hydraulic control check valve and the second hydraulic control check valve. Two hydraulic control check valves; one oil port and the control oil port of the first hydraulic control check valve are respectively connected with two oil passages between the two-way quantitative pump 23 and the low-speed high-torque hydraulic motor 26, and the second hydraulic control check valve One oil port of the valve is connected to the oil passage connected to the control oil port of the first hydraulic control check valve, and the control oil port of the second hydraulic control check valve is connected to an oil port of the first hydraulic control check valve. The connected oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com