LED chip construction and manufacturing method thereof

A technology of light emitting diode and chip structure, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low light extraction rate, low light extraction efficiency, increased production cost, etc. problem solving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The contents, advantages and objects of the present invention will be set forth in the following description of the embodiments.

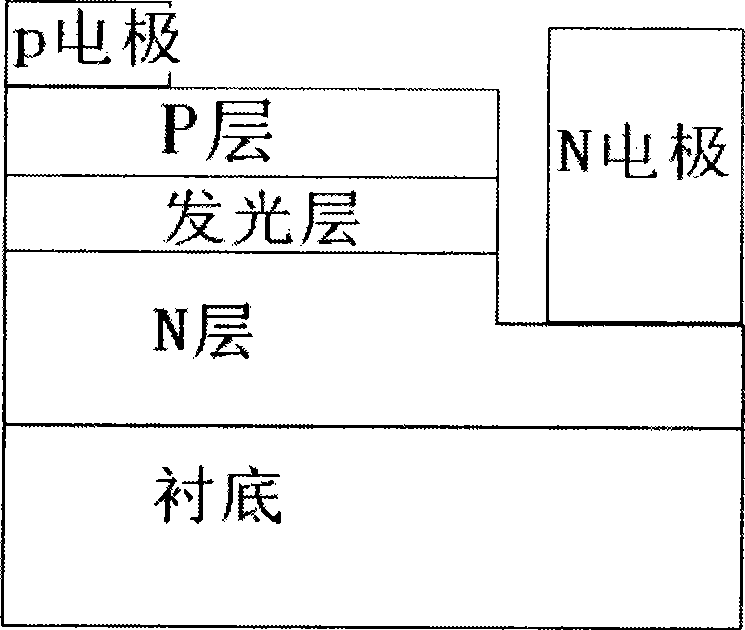

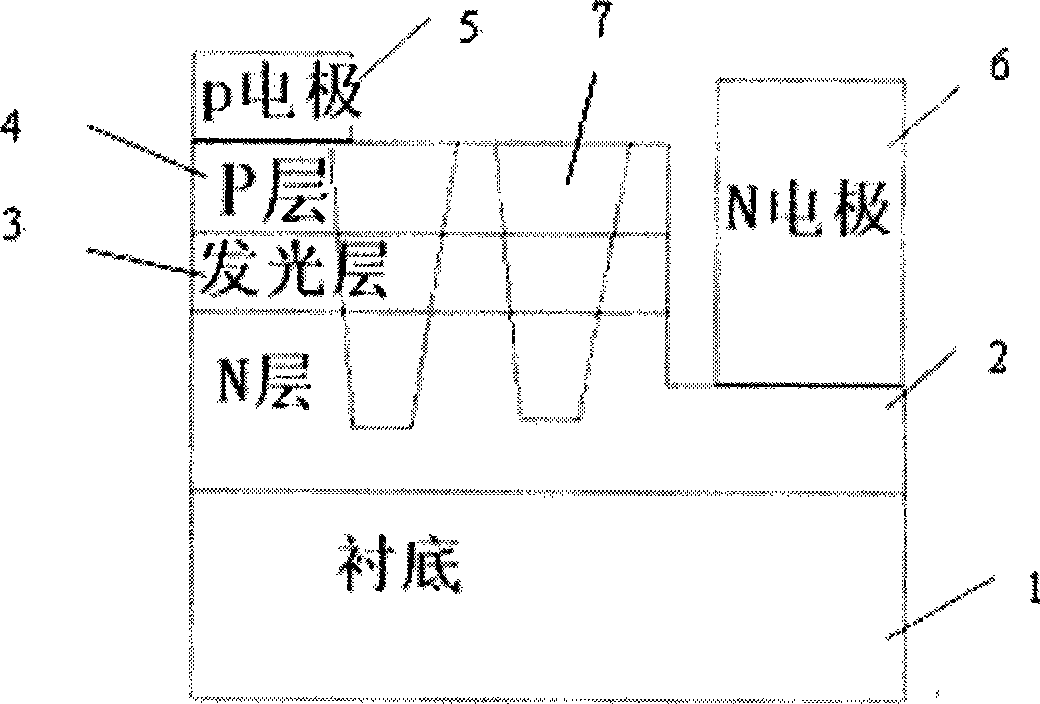

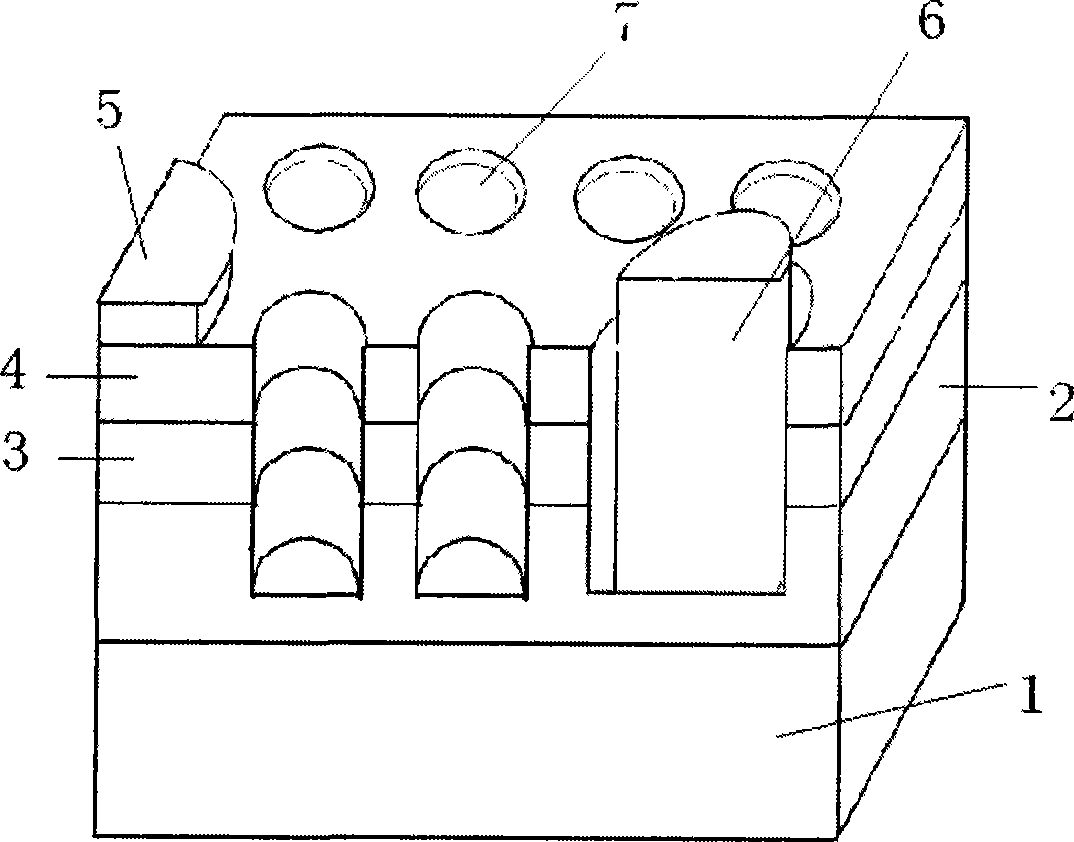

[0028] In the structural design of light-emitting chips, two problems urgently need to be solved are to provide good heat dissipation structure design and good current distribution to reduce chip temperature and improve light extraction efficiency. The present invention solves the above two problems at the same time through an ingenious structural design. On the premise of providing good heat dissipation, more light-emitting surfaces are provided so that light can be emitted from the side and the top surface at the same time. At the same time, due to the good current distribution design provided in both the P layer and the N layer, the current distribution is more uniform and reasonable. This kind of design can not only be used for general light-emitting chip design but also especially suitable for high-current power-type light-emitting diod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com