Hot-melt adhesive for fixing IC module, and laminated tape and IC card using the adhesive

A hot-melt adhesive and adhesive technology, applied in the directions of adhesives, record carriers used in machines, adhesive types, etc., can solve the problems of difficulty in detecting IC chips, reduced workability, low transparency, etc., and achieve excellent visible light transmittance and Effects of bond strength, easy detection, excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

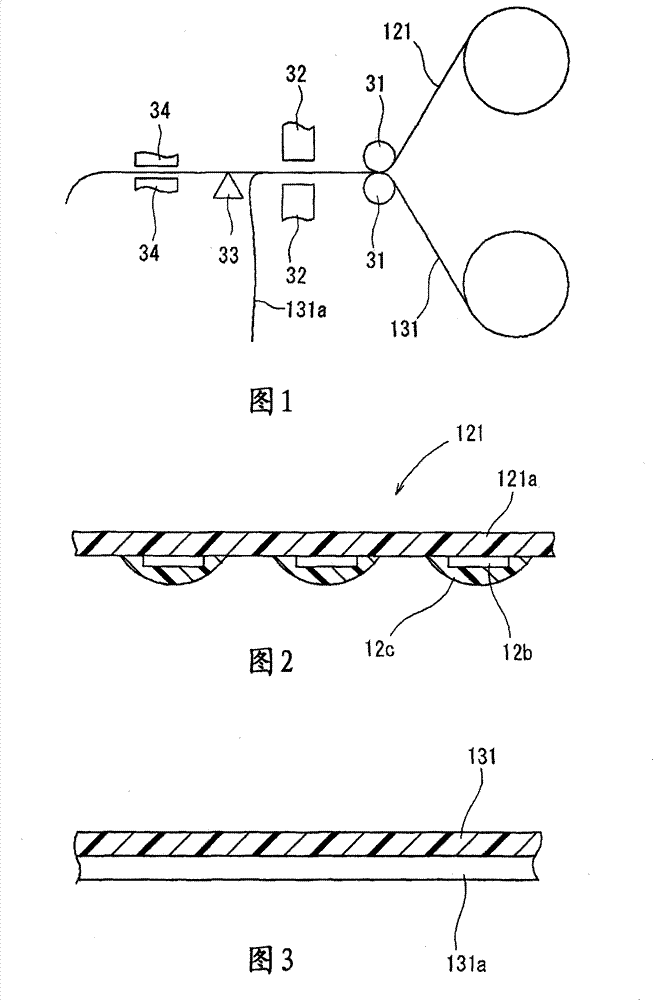

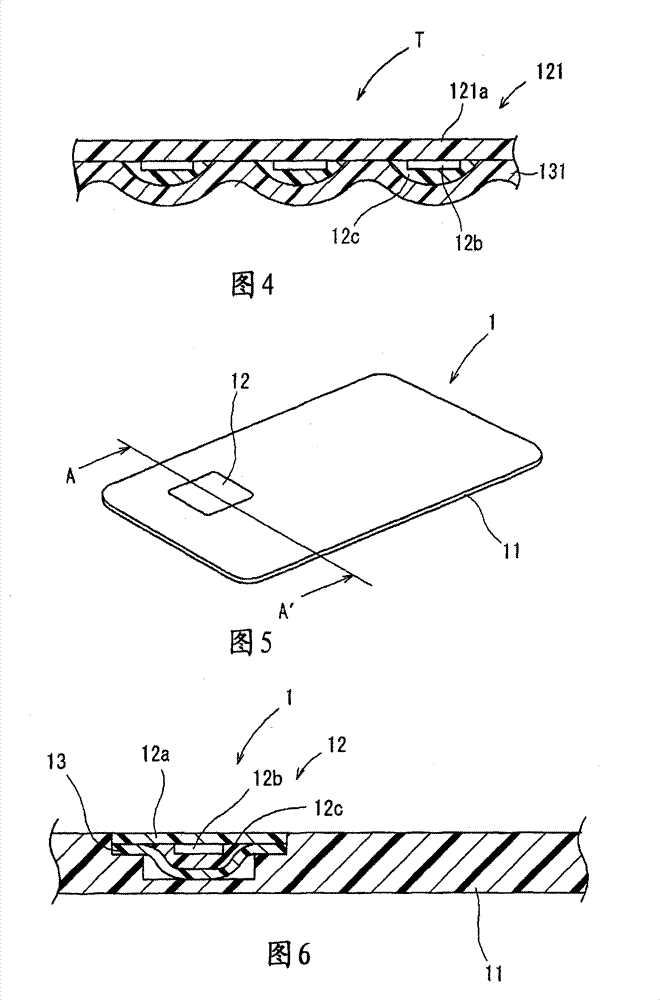

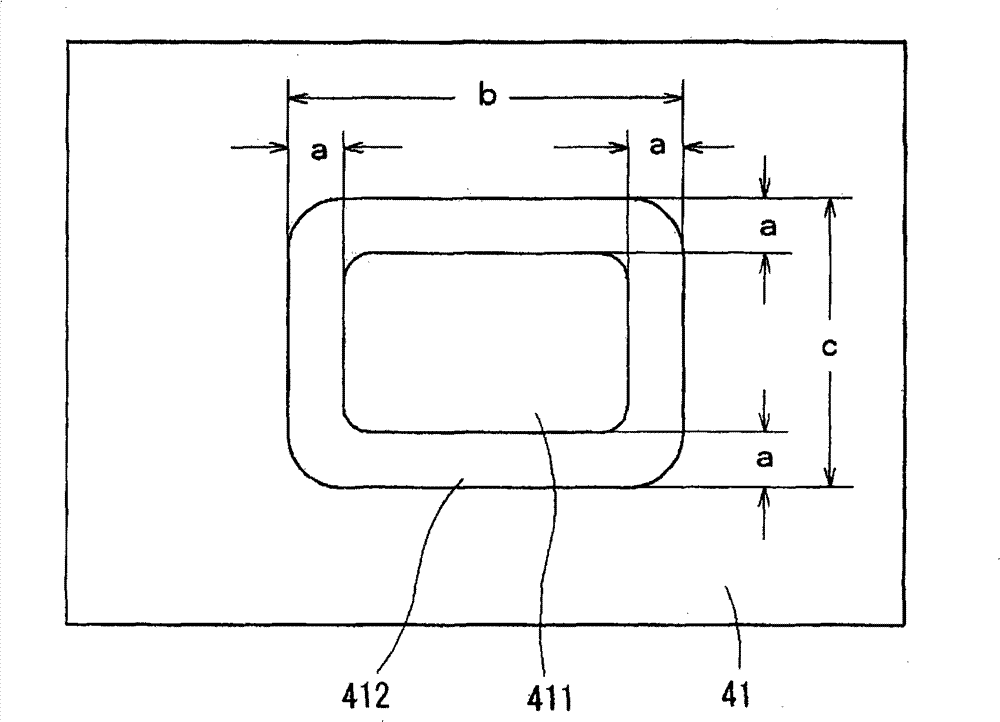

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~3

[0099] Use the saturated polyester resin described in Table 1, as well as epoxy resin, inorganic filler, and hydrolytic agent according to the ratio described in Table 2 and Table 3, and use a twin-screw type mixer to manufacture hot melt for fixing IC modules adhesive.

[0100] As the epoxy resin, the inorganic filler, and the hydrolysis agent, the following substances were used, respectively.

[0101] Epoxy resin: Bisphenol A type, manufactured by Japan Epoxy Co., Ltd., trade name "EP-1007"

[0102] Inorganic filler: Talc, manufactured by Fuji Fine Co., Ltd., trade name "RKP-80"

[0103] Waterproofing agent: polycarbodiimide, manufactured by Sumitomo Bayer Polyurethane Co., Ltd., trade name "NPE"

[0104] The performance of each hot melt adhesive for fixing IC modules was evaluated as described below.

[0105] (1) Visible light transmittance

[0106] The transmittance at a wavelength of 600 nm was measured using a spectrophotometer.

[0107] Measuring device: Spectrophotometer (manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com