High-strength aluminum alloy plate and process for producing the same

An aluminum alloy plate and a manufacturing method technology, which are applied in the directions of metal rolling, transportation and packaging, thin material processing, etc., can solve the problems of no recrystallized grain size and surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

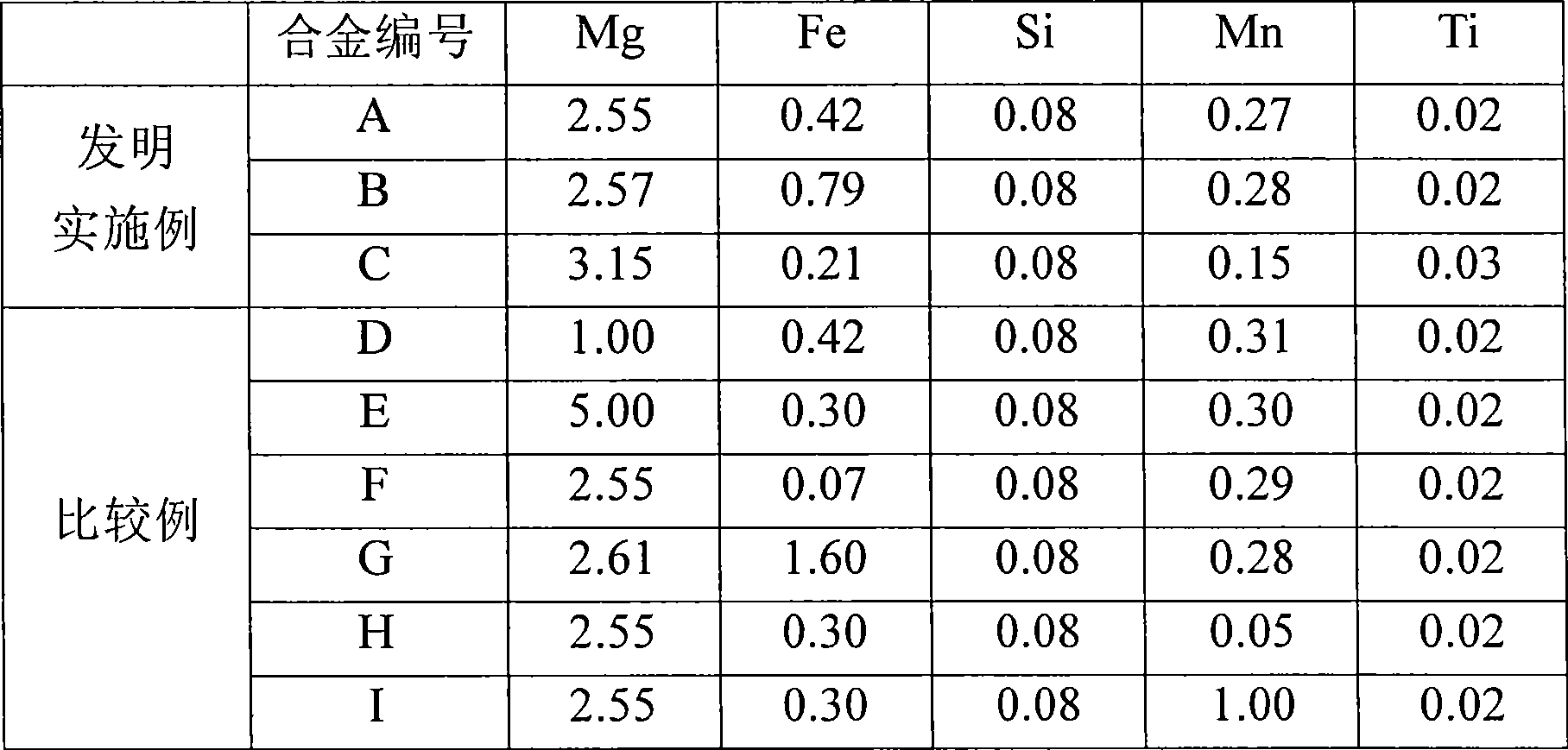

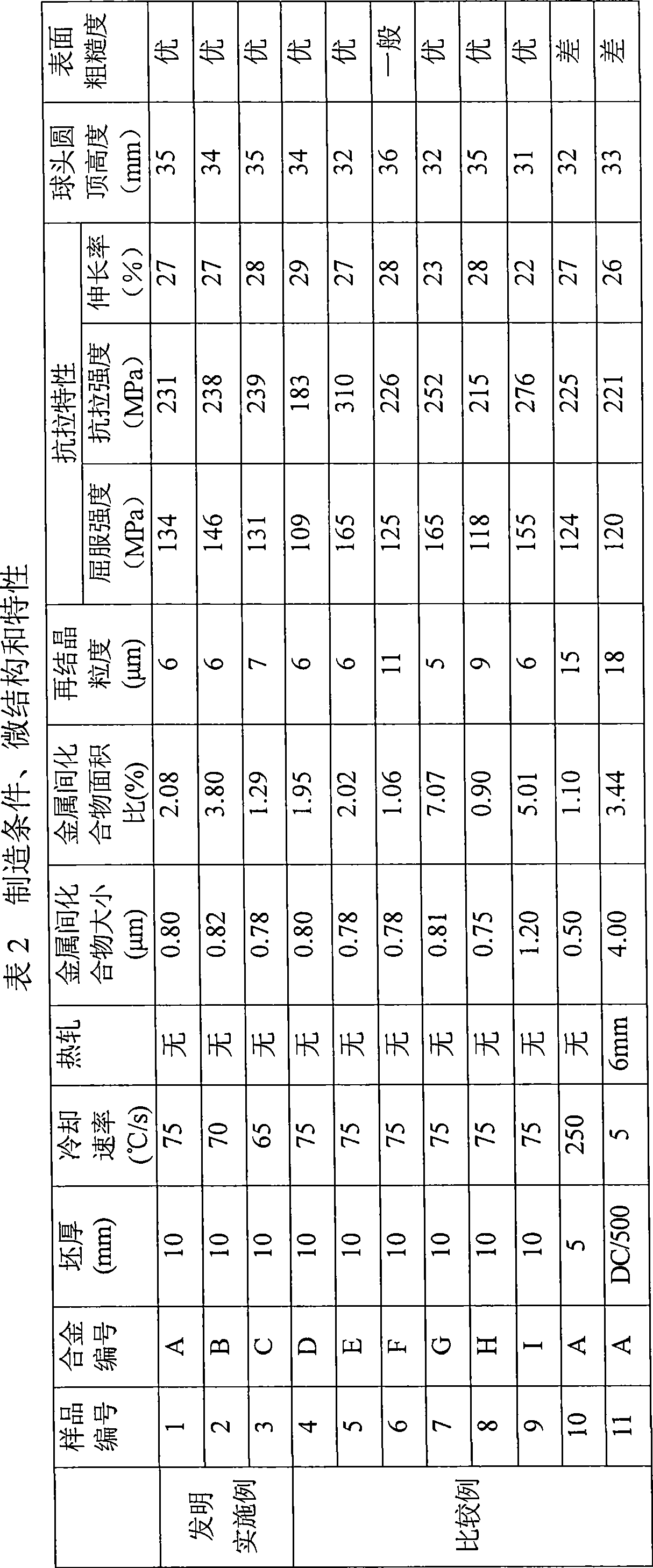

[0050] Alloy melts with various chemical compositions as shown in Table 1 were fabricated, cast into slabs with a thickness of 10 mm by a twin-belt casting machine, and directly wound into coils.

[0051] Table 1 Alloy composition (mass%)

[0052]

[0053] As a comparative example, a melt of alloy composition A was prepared, cast into a slab with a thickness of 5 mm by a twin-belt casting machine, and directly wound into a coil.

[0054] In addition, as a separate comparative example, the melt of the alloy composition A is cast into a slab with a thickness of 500 mm by a DC casting machine, which is further scalped and homogenized, and hot-rolled by a rolling mill to obtain Hot-rolled sheet with a thickness of 6mm.

[0055] Next, these slabs were cold-rolled using a cold rolling mill, and hot-rolled sheets were obtained into coils having a thickness of 1 mm. The coils were passed through a continuous annealing line (CAL) and annealed at 425°C for 15 seconds.

[0056] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com