Sewage Heat Energy Recovery System

A heat energy recovery and sewage technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration loop, etc., can solve the problems of heat exchanger blockage, labor consumption, pollution, etc. The effect of improving heat exchange efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

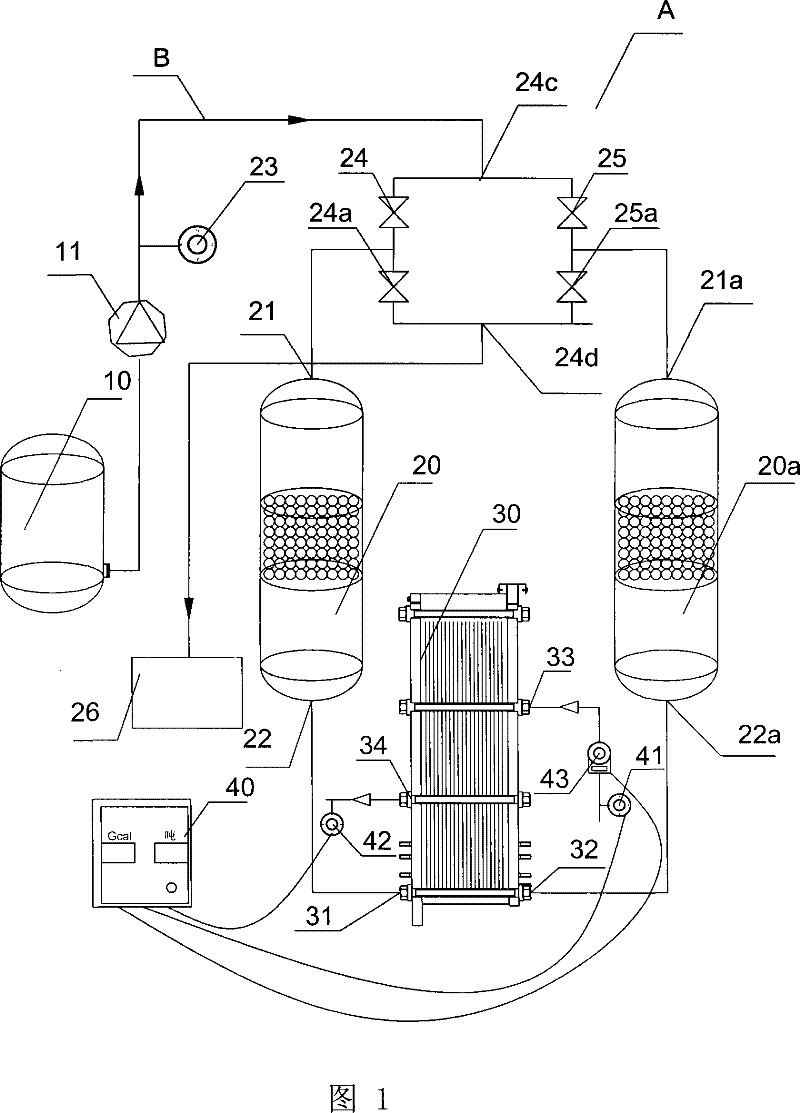

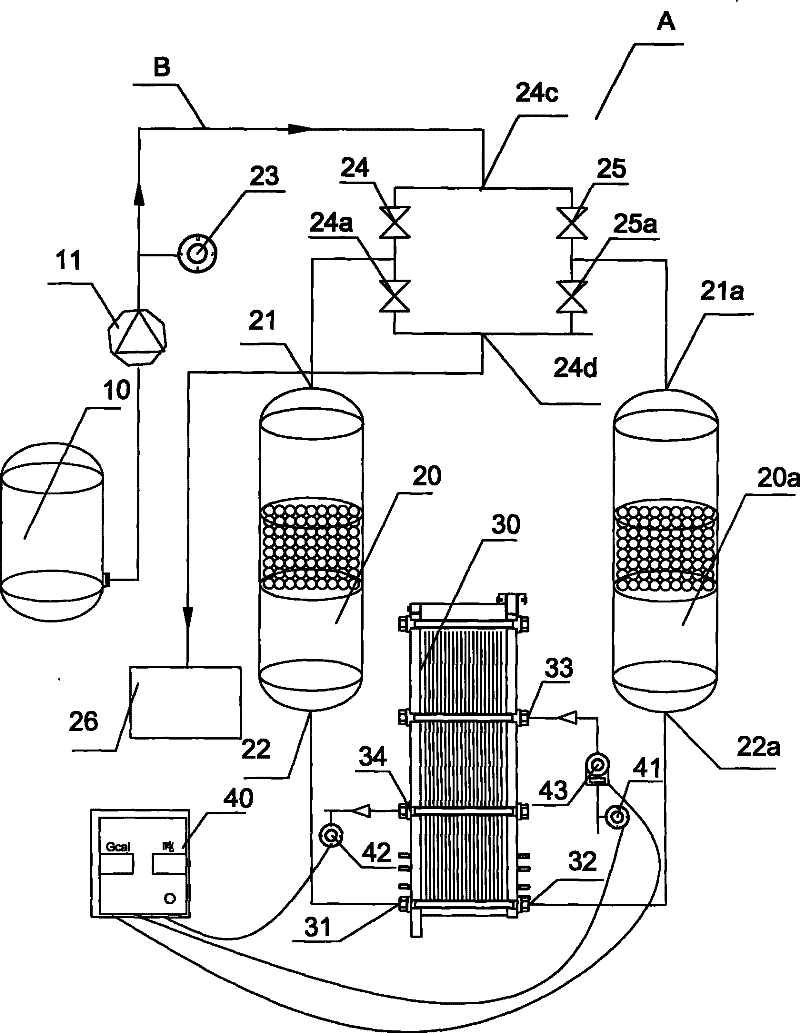

[0016] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] figure 1 The flow direction pointed by the middle arrow is the water flow direction of the whole system. The high-temperature sewage is first collected centrally and then enters the filter. The filter is two parallel left particle filter 20 and right particle filter 20a of the same specification and type. , the whole cylinder is in the shape of a cylinder, the top of the filter is provided with a left sewage inlet 21 and a right sewage inlet 21a, and the bottom is provided with a left filtered water outlet 22 and a right filtered water outlet 22a; above the sewage inlets of the two filters, there is a Bridge valve A, the bridge valve includes two groups of side-by-side group valves, and each row of group valves includes two single valves in series, which are respectively upper left valve 24, lower left valve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com