Material level detecting method for tube mill based on multi-sensor fusing technology

A multi-sensor fusion and material level detection technology, which is applied in the direction of machines/engines, instruments, mechanical equipment, etc., can solve the problems of inaccurate reflection of ball mill material level information, high cost, and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

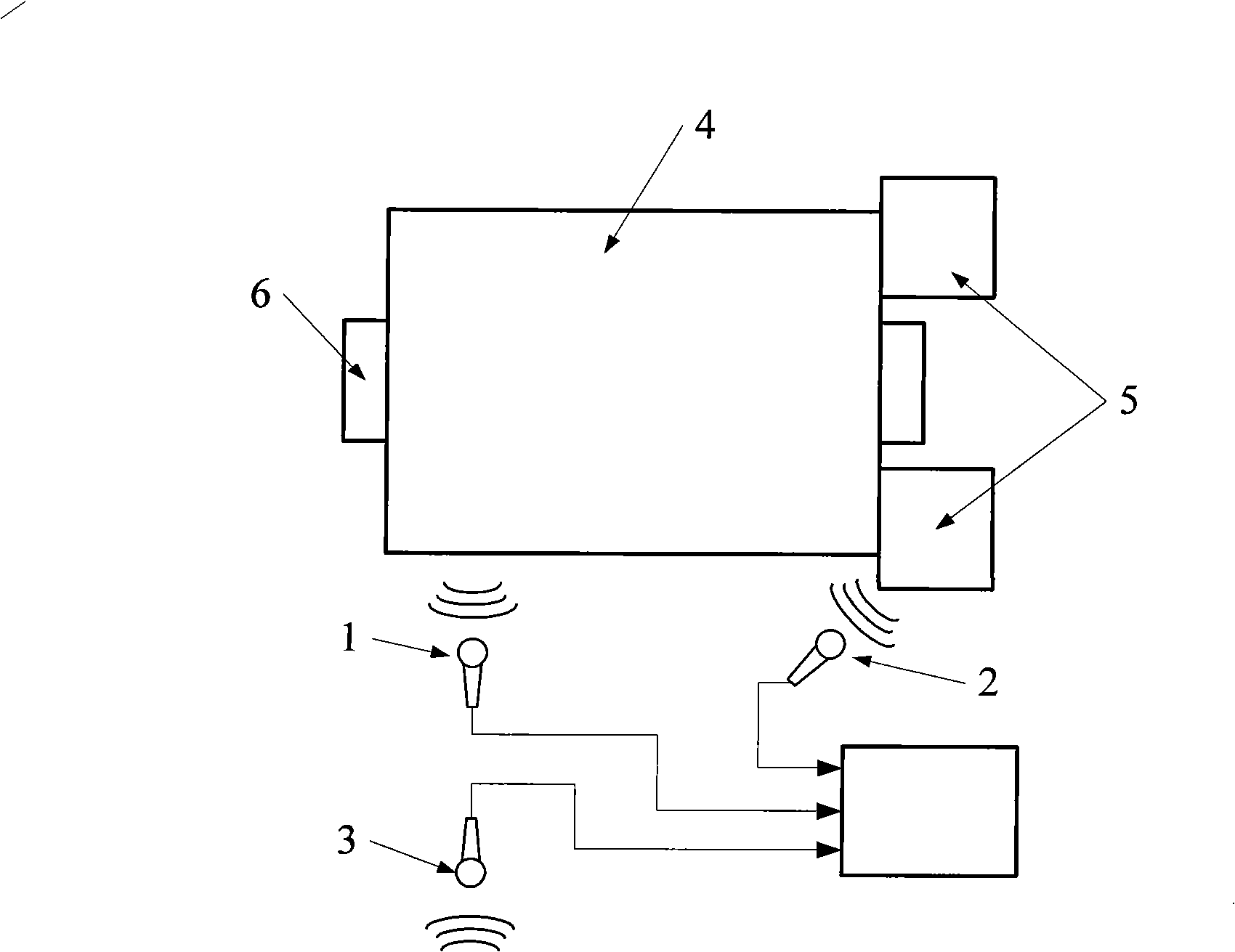

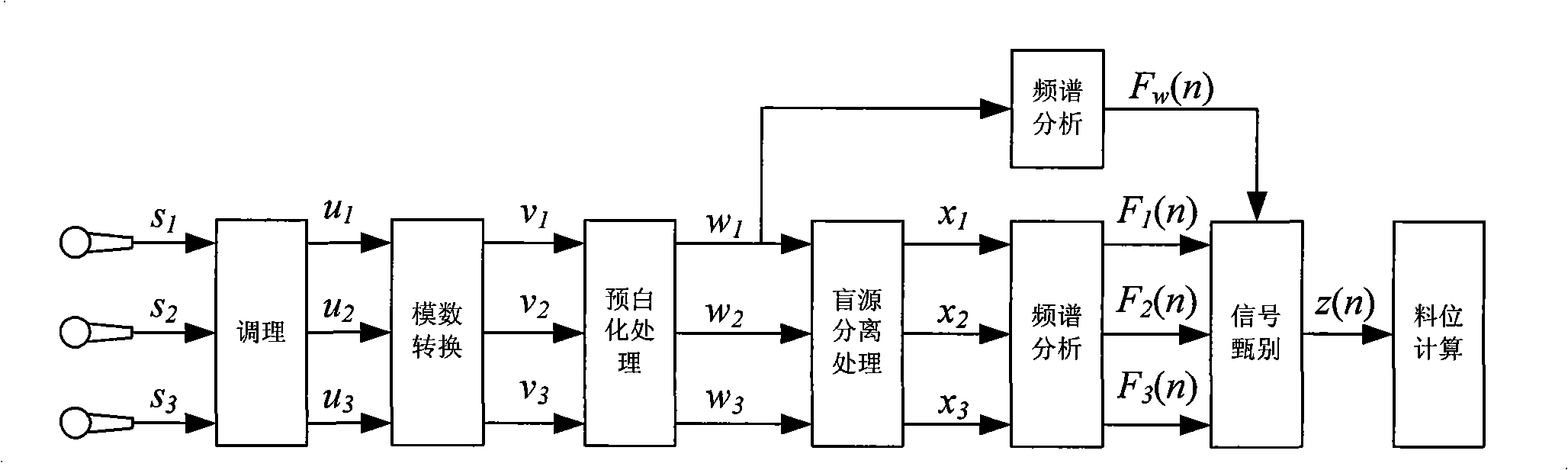

[0029] Such as figure 1 , 2 As shown, the method of detecting the material level of the roller ball mill based on the multi-sensor fusion technology, the steps are as follows:

[0030] (1) At the same time, three audio sensors are used to collect the noise signal s at the drum of the drum ball mill. 1 , The noise signal s of the place where the background noise of the roller ball mill itself is relatively high (generally refers to the position of the machine body running part and the motor transmission mechanism) 2 , and the noise signal s of the environment where the roller ball mill is located 3 ;

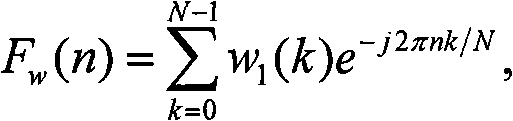

[0031] (2), to the noise signal s that step (1) collects 1 ,s 2 ,s 3 Conditioned signal u 1 , u 2 , u 3 , will signal u 1 , u 2 , u 3 Analog-to-digital converted digital sequence signal v 1 , v 2 , v 3 , then the digital sequence signal v 1 , v 2 , v 3 The pre-whitened signal w 1 ,w 2 ,w 3 , where, for the noise signal s 1 ,s 2 ,s 3 The signal u obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com