Thermocouple with micron or nanometer grade tip curvature radius and method for producing the same

A technology of curvature radius and manufacturing method, which is applied in the field of thermal detection, can solve problems affecting fluid temperature field and measurement accuracy, fluid motion interference, etc., and achieve the effect of overcoming the influence of response frequency, improving spatial resolution, and increasing response frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

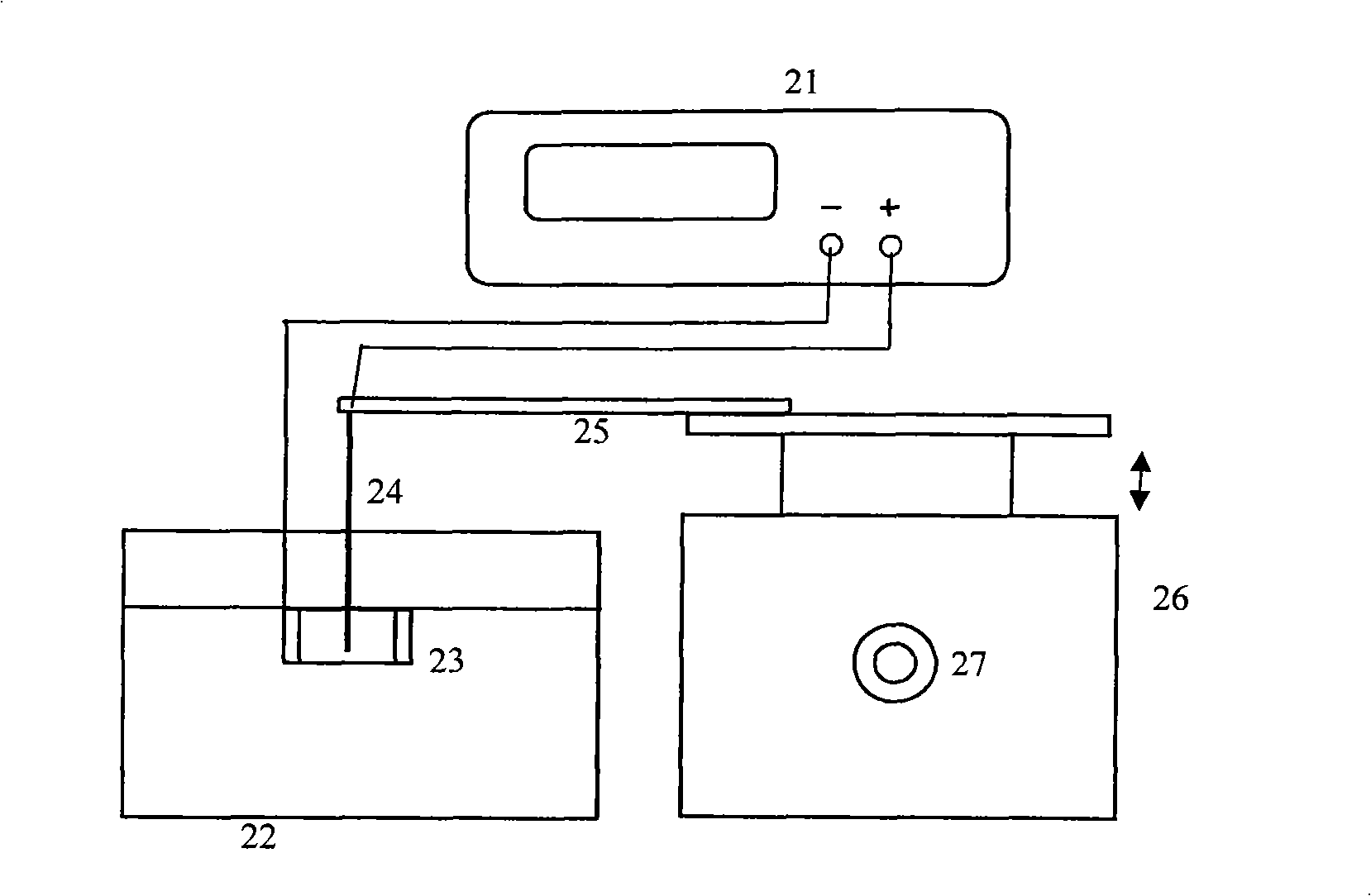

[0026] To prepare T-type micro / nano thermocouples (constantan and copper), use constantan wire as the substrate, first select the constantan wire with a diameter of 0.3mm, and use the electrochemical corrosion method to prepare micron-scale needle points. The device (such as figure 2 ) includes a programmable power supply 21, a vessel 22 filled with corrosive solution, an annular graphite electrode 23 as a cathode, a transmission connecting rod 25, and a micron displacement platform 26.

[0027] The first step is to straighten the constantan wire to be corroded, anneal it, cut it into 8cm small sections 24, and fix it on the micron displacement platform 26 which can be adjusted up and down accurately through the transmission connecting rod 25, and adjust it vertically to the corrosion liquid surface, and slowly adjust it downward. The knob 27 makes the constantan wire 24 just touch the corrosion liquid surface, and from this point, the insertion depth of the constantan wire in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com