Reinforced core of composite material optical cable and optical cable using the reinforced core

A technology of fiber optic cable strengthening core and composite material, applied in the direction of fiber mechanical structure, etc., can solve the problems of poor anti-folding performance, high cost, small size, etc., and achieve the effects of convenient installation, construction and laying, large transmission information capacity and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

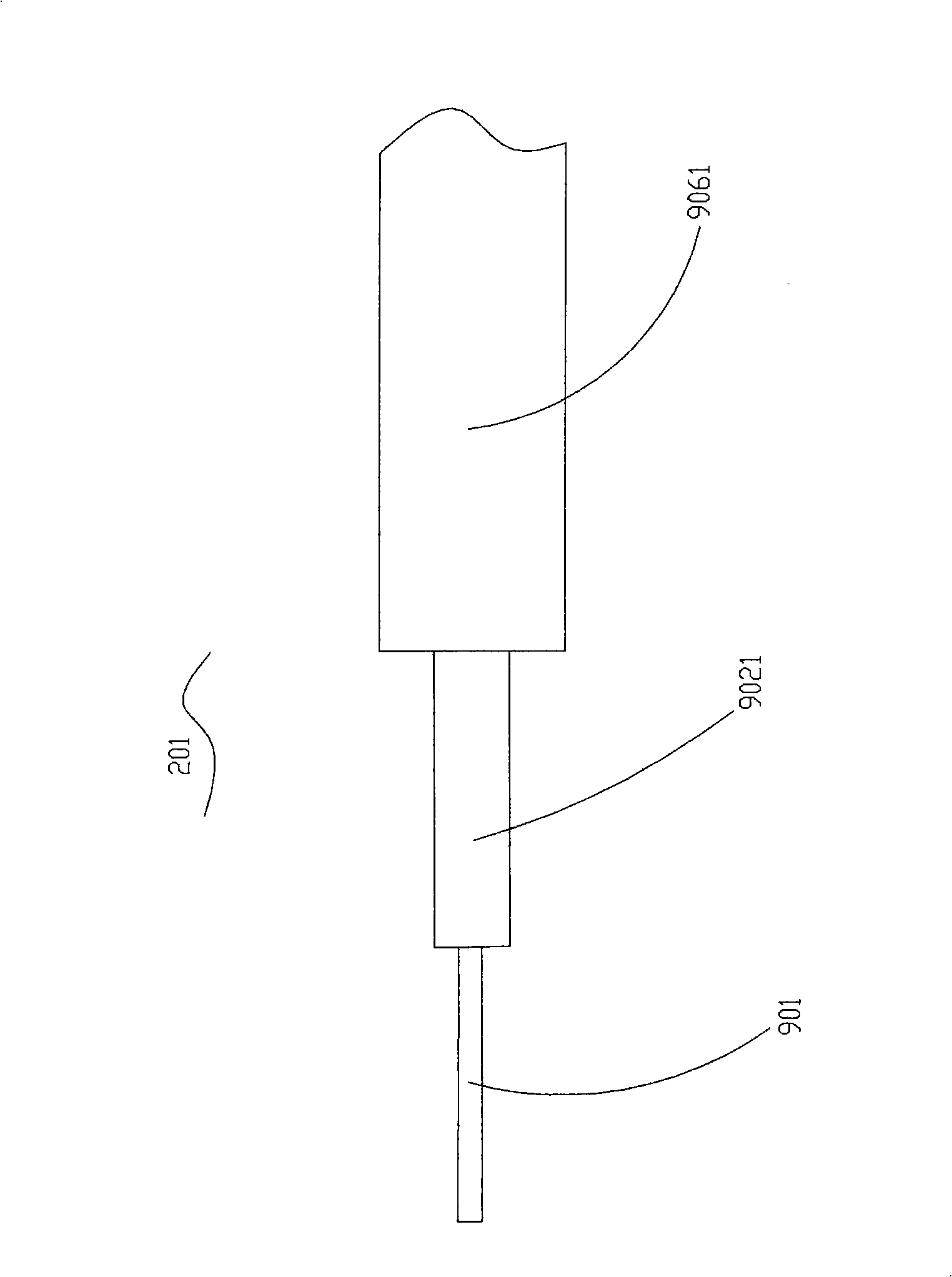

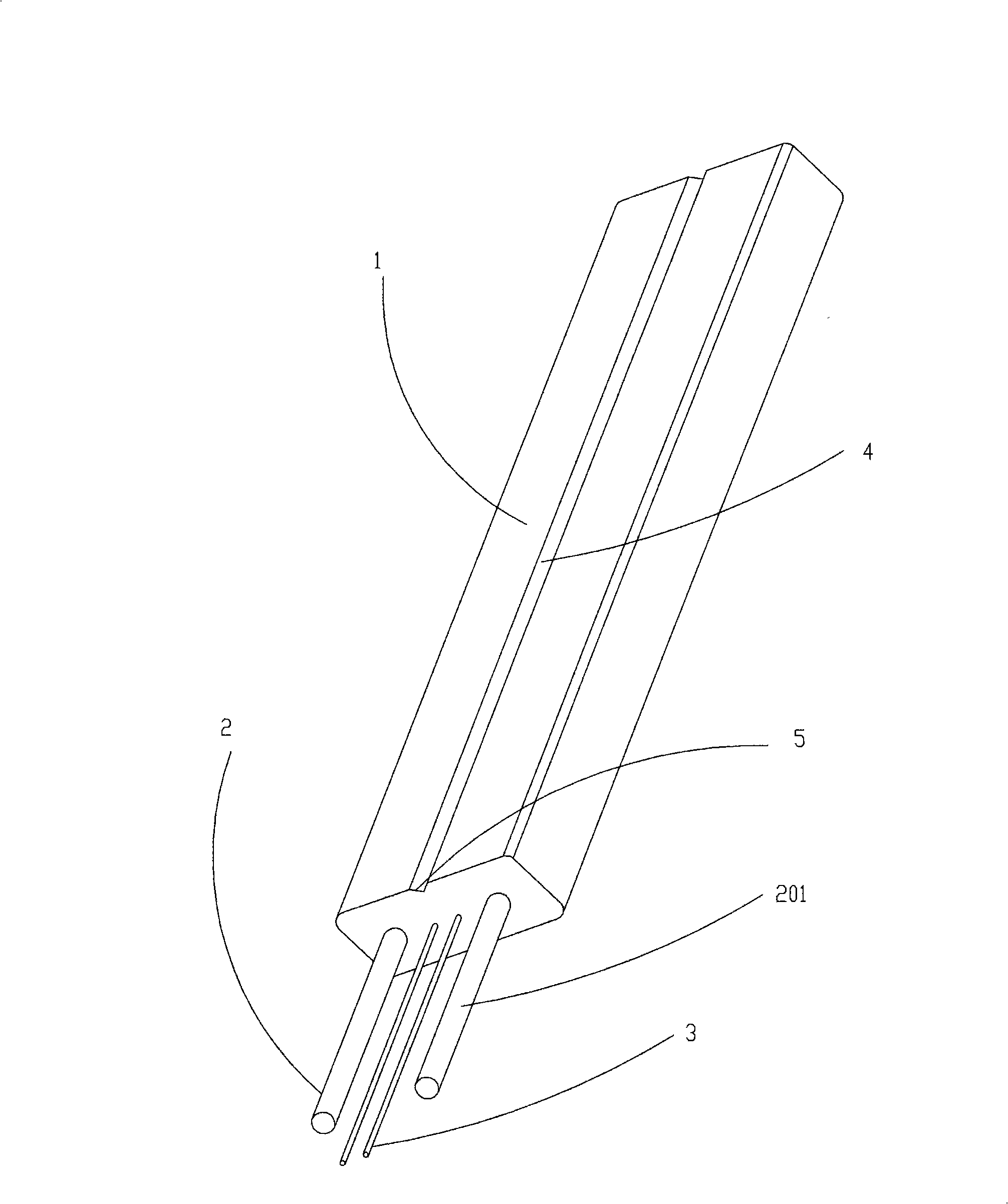

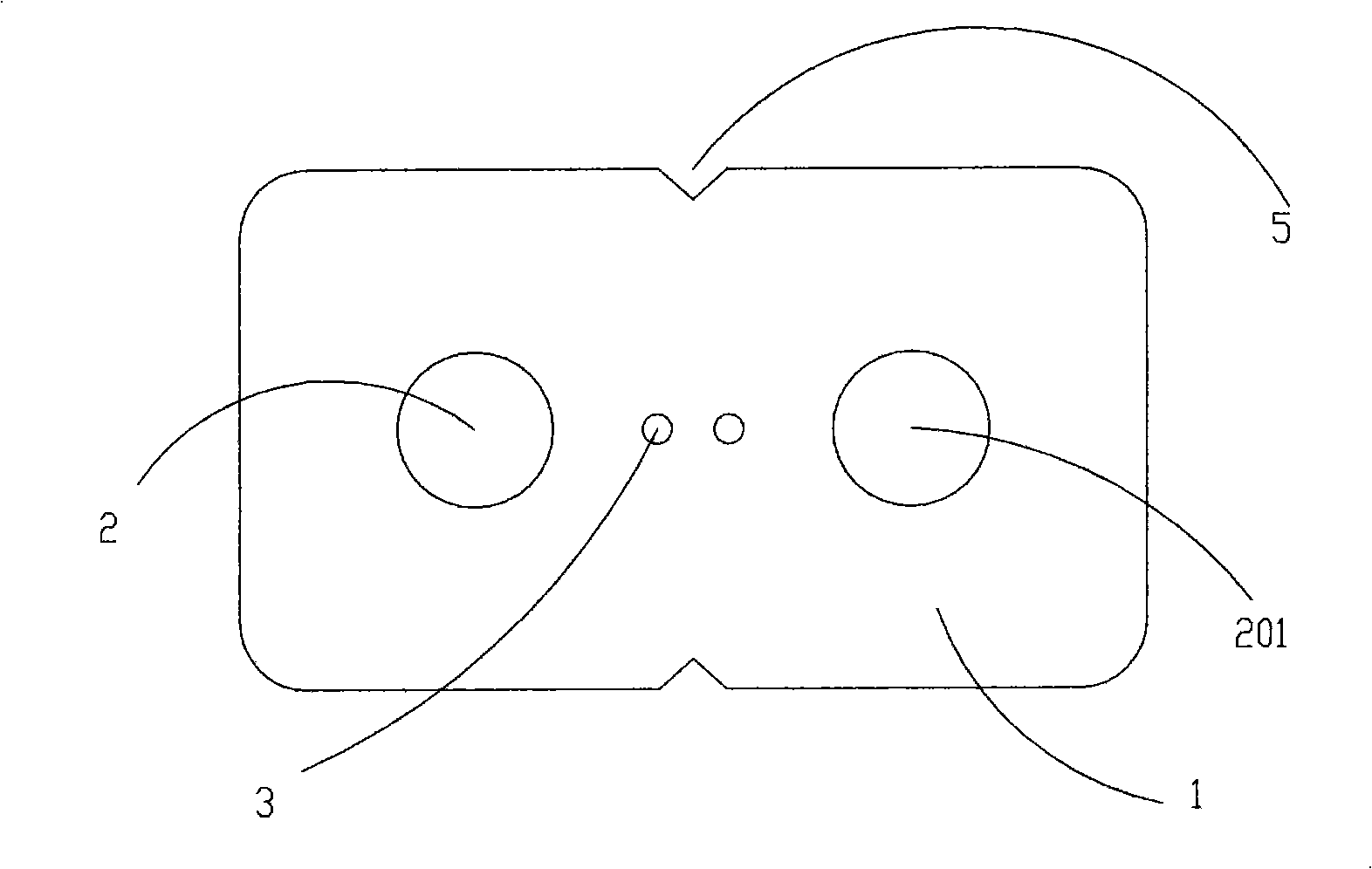

[0017] The reinforced core of the composite optical cable and the optical cable using the reinforced core of the present invention are small-sized (size 2×3MM) communication optical cables suitable for FTTH terminal wiring, and are especially suitable for indoor wiring in buildings, hotels, offices, etc. As shown in the figure, it includes: 1. Sheath cable body, 2. Strengthening member, 201, Composite optical cable strengthening core, 3. Optical fiber, 4. Groove, 5. Opening.

[0018] The optical cable using the strengthening core is roughly rectangular in shape, which includes a sheathed cable body 1, two composite material optical fiber cable strengthening cores 201 integrated in the sheathed cable body 1 symmetrically and two integrated in the sheathed cable body 1. The composite material optical cable strengthens the optical fiber 3 between the cores 201 . The sheathed cable body 1 is made of environmentally friendly halogen-free flame-retardant high-elastic polyolefin mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com