Method for TiNi alloy stent with phosphorus injection and slow neutron irradiation activation

A slow neutron and alloy technology, applied in the field of phosphorus injection of TiNi alloy stents, can solve the problem of weak radiation penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

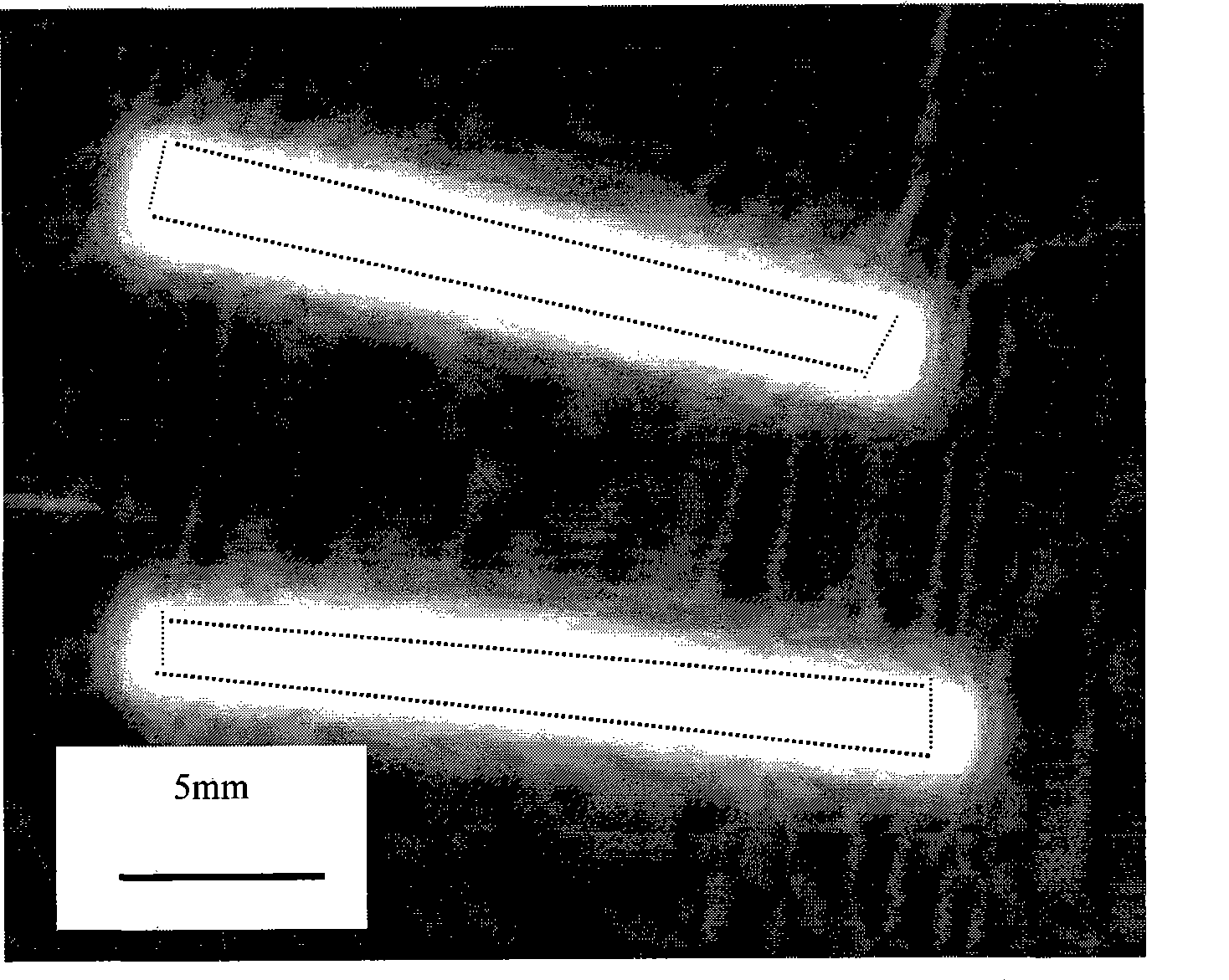

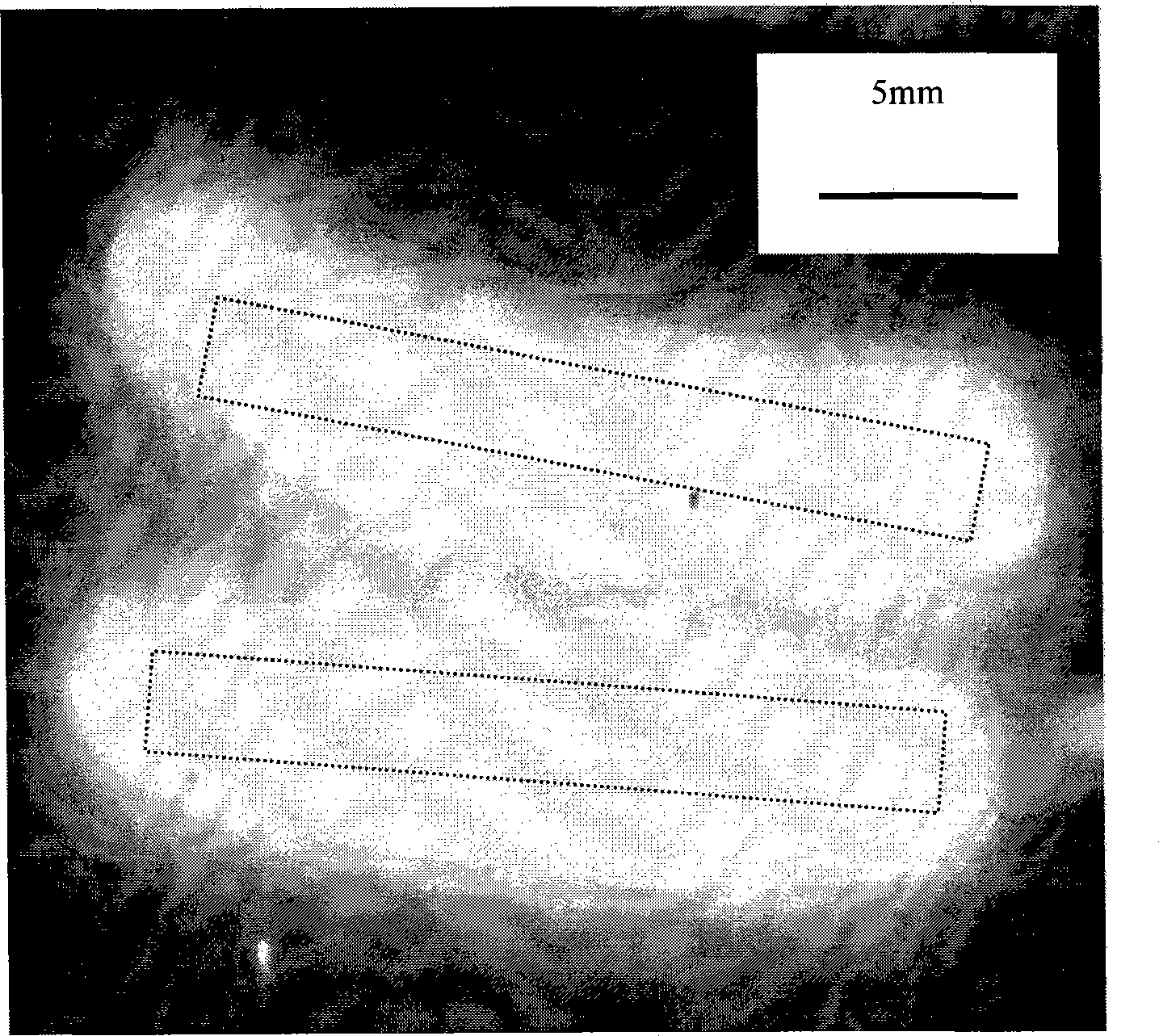

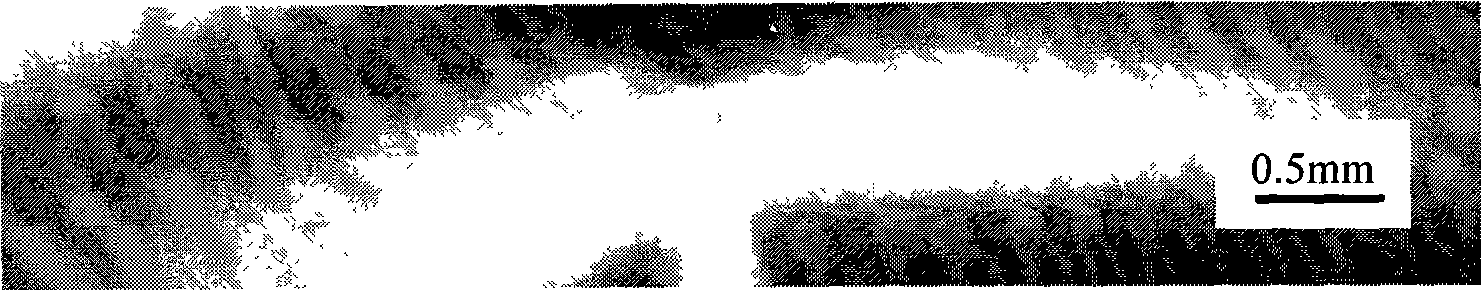

[0010] Specific Embodiment 1: In this embodiment, the method for slow neutron irradiation activation after phosphorus injection of TiNi alloy stent is realized according to the following steps: 1. Chemical polishing: put the TiNi alloy stent into HF / HNO at a temperature of 40-60°C 3 / H 2 Soak in O system for 5-15s, then put it into acetone and ultrasonically clean it for 20-60 minutes, and then dry it; 2. Phosphorus injection: use red phosphorus as the ion source, heat the ion source to vaporize, pulse high-pressure to ionize it, and then When the injection voltage is 30-90KV, the injection amount is 4×10 17 P / cm 2 , The pulse current is 20-30A, the frequency is 100-200Hz, the pulse width is 40-60μs, the first gate is 0.3-1kV, and the second gate is 0.5-1.5kV. Phosphorus is injected under the conditions; 3. Slow neutron irradiation activation: At a slow neutron flux of 5.88×10 17 n / m 2 s. The dose of slow neutron radiation is 1.69×10 22 n / m 2 Under the conditions of irra...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment is different from Embodiment 1 in that the temperature in step 1 is 45-55°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the temperature in step 1 is 50°C. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com