Aggregate machinery for machining large-sized mechanical components

A combined machine tool and large-scale machinery technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of many auxiliary man-hours, large floor space, and large cumulative error of machining accuracy, saving auxiliary man-hours and shortening the processing period. , The effect of equipment investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

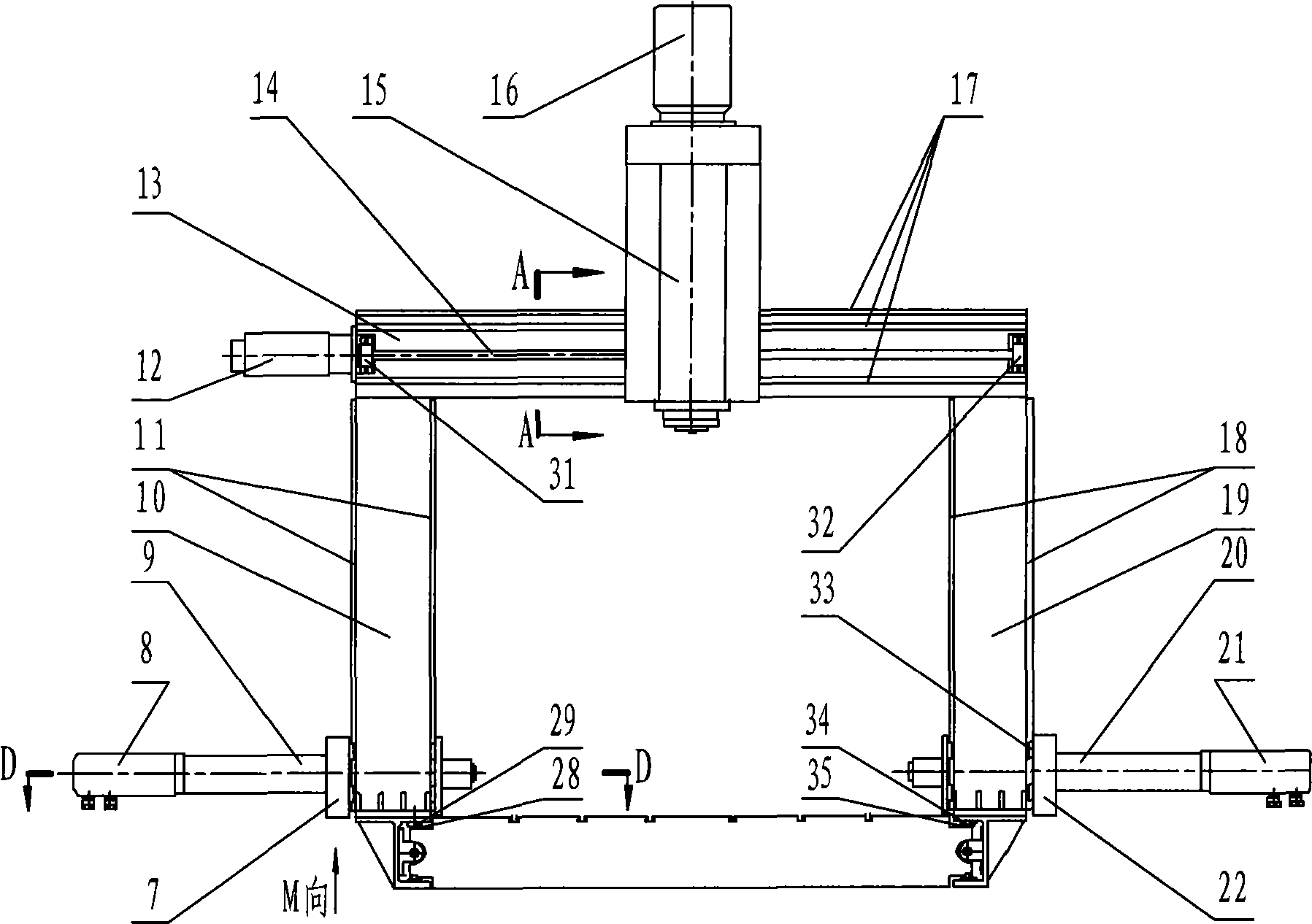

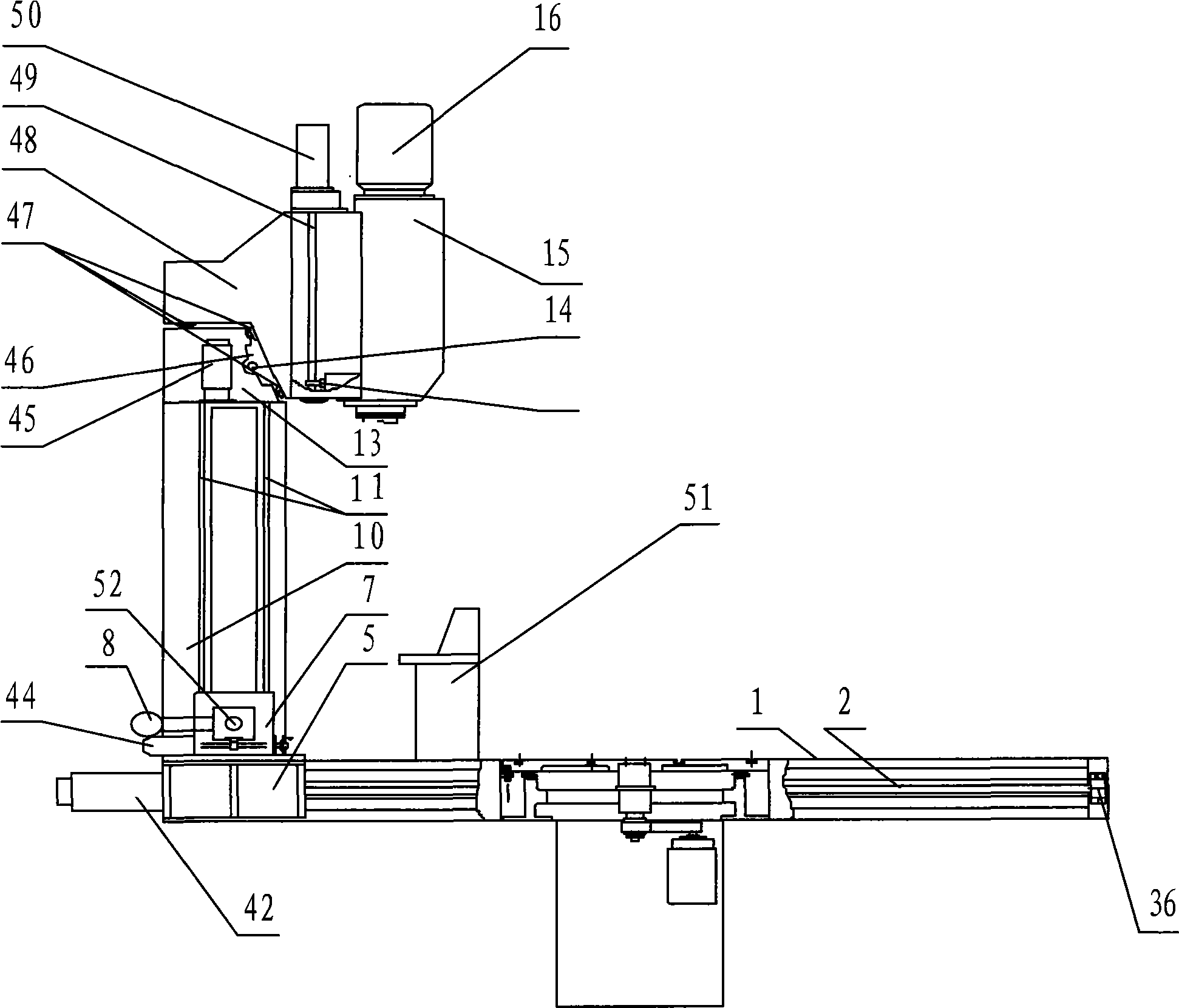

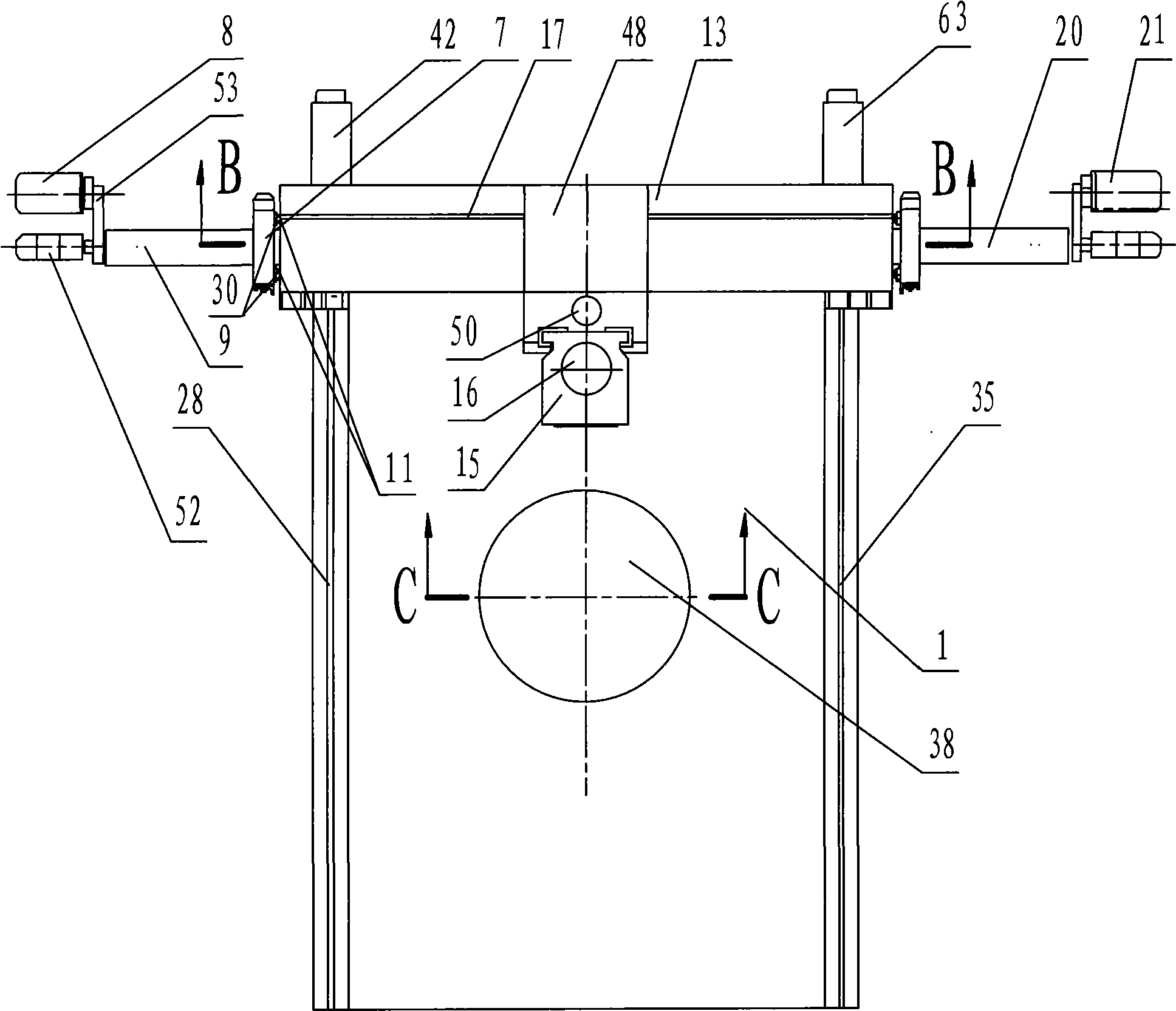

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

[0029] Domestic large-scale machinery, metallurgy, mining, electric power, mold, wind power and other equipment manufacturing industries use general-purpose equipment to process parts and components. The single-machine processing performance and service range are limited, and they are used to process large-scale and complex-structured parts. It is very difficult, especially for a product that needs multiple processes such as vertical boring, vertical milling, horizontal boring, horizontal milling, and vertical turning to complete the processing of a part. It requires a fleet of multiple equipment to complete the processing, and the processing process requires multiple transfers. , Repeated clamping and positioning, that is, a lot of auxiliary man-hours are wasted, and the processing cycle is prolonged. At the same time, multiple turning and positioning will inevitably cause cum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com