Semiconductor device having insulated gate semiconductor element, and insulated gate bipolar transistor

A semiconductor and insulated gate technology, which is applied in the field of insulated gate bipolar transistors, can solve the problems that the device is prone to electromagnetic noise, the electric field distribution of the silicon substrate is uneven, and it is difficult to increase the breakdown voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

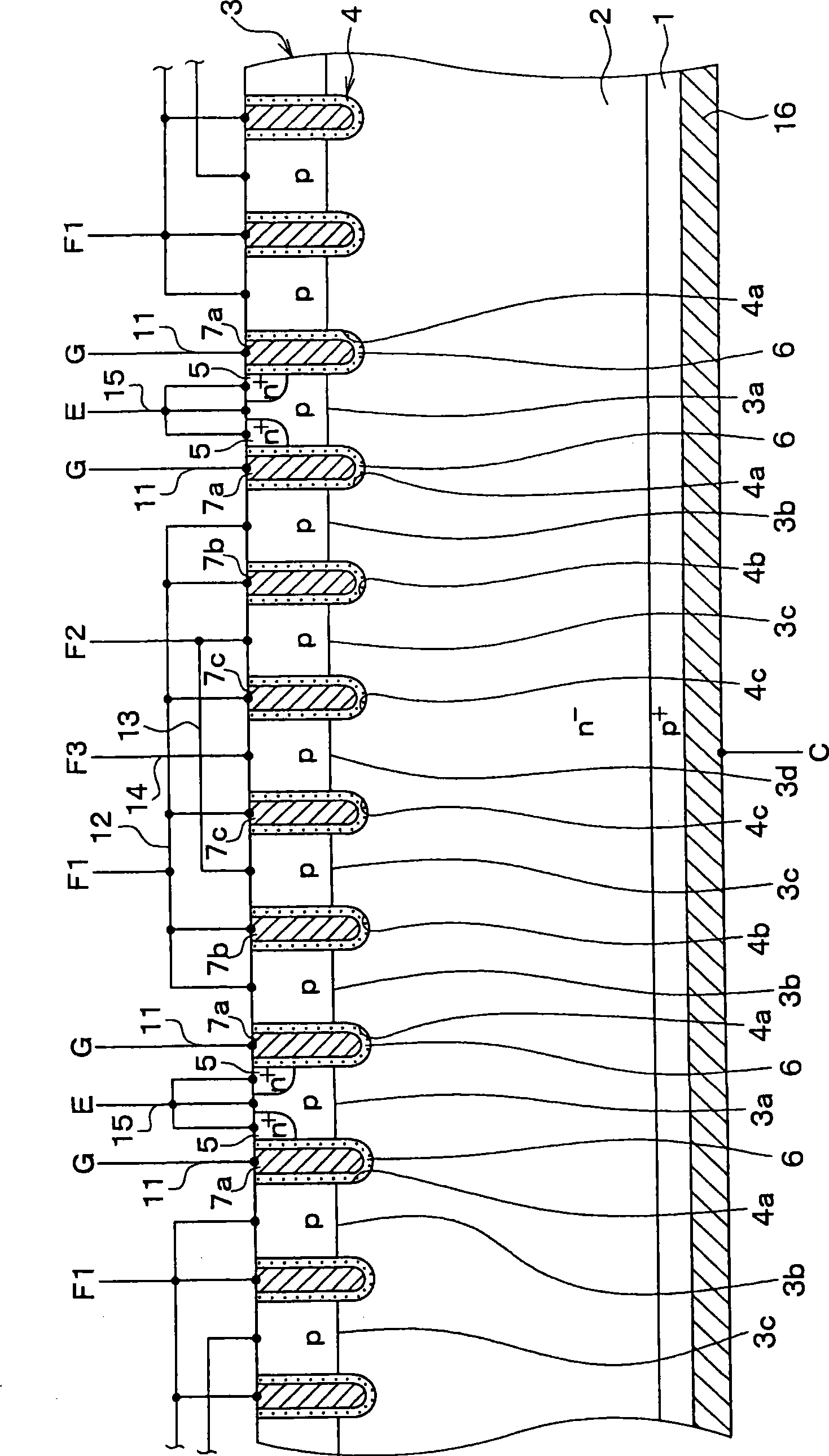

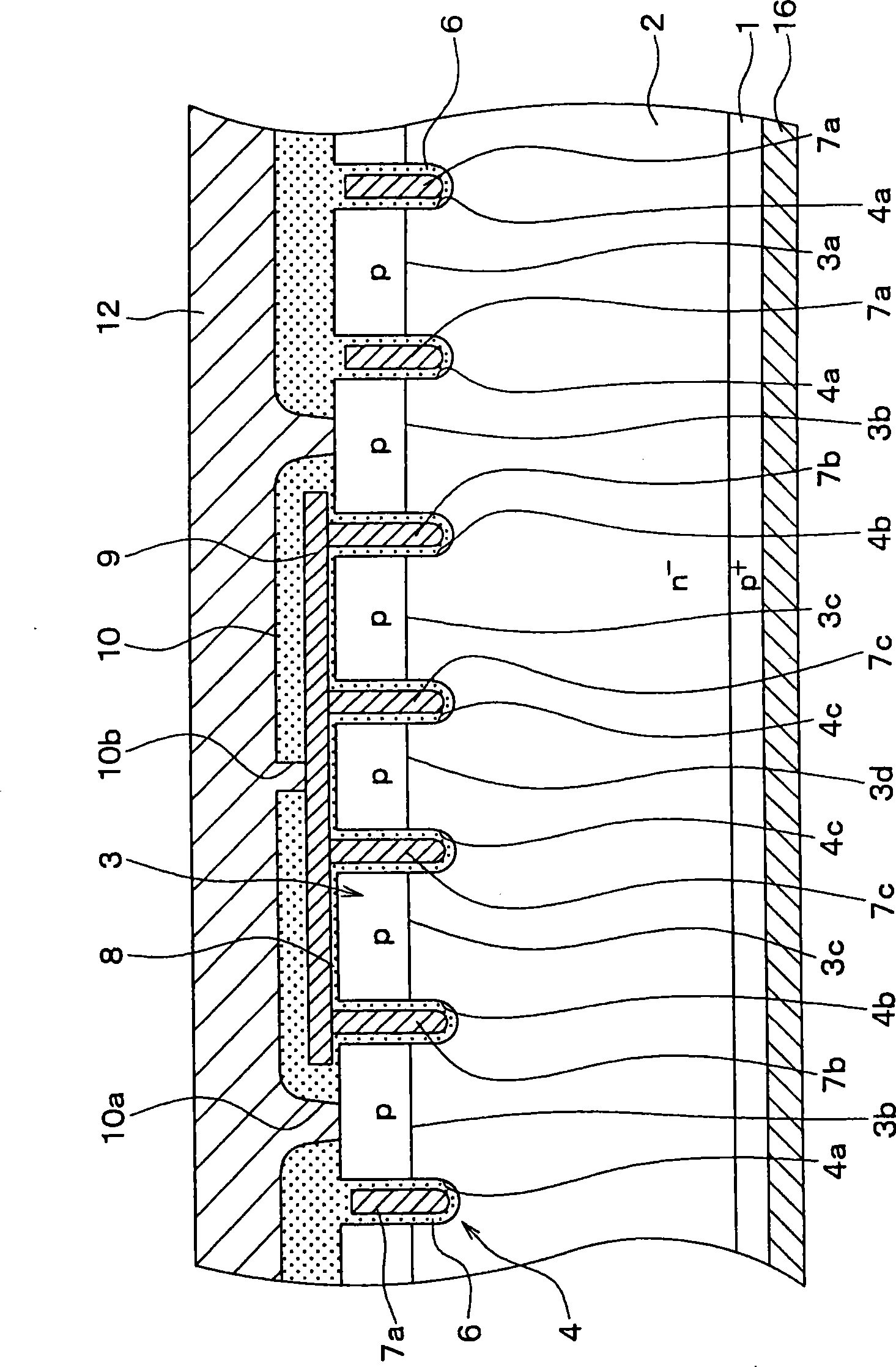

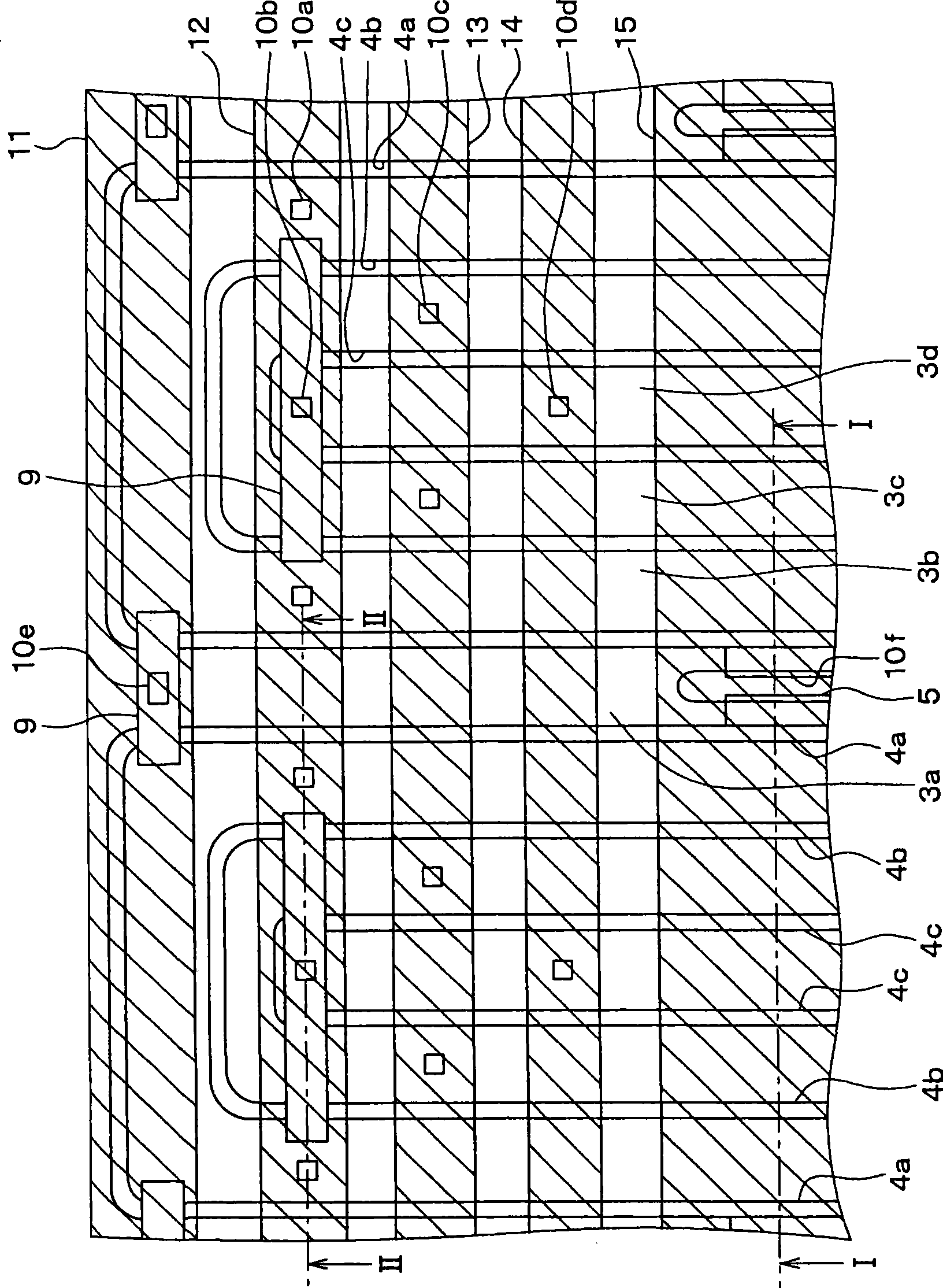

[0064] figure 1 shows along the image 3 A semiconductor device with an IGBT intercepted by the line I-I in . figure 2 shows along the image 3 The device intercepted by the line II-II. although image 3 Not a sectional view, but image 3 There are shaded areas in , to facilitate understanding of the structure.

[0065] In P with a major surface + The IGBT is formed in the substrate 1. Substrate 1 has a high impurity concentration. N is formed on the main surface of the substrate 1 by an epitaxial growth method - Type drift layer 2. Drift layer 2 has a lower impurity concentration than substrate 1 .

[0066] P-type base region 3 having a predetermined thickness is formed in a surface portion of drift layer 2 . A plurality of trenches 4 are formed on the substrate 1 such that each trench 4 penetrates the base region 3 and reaches the drift layer 2 . Base region 3 is divided into a plurality of base portions by trenches 4 . Specifically, grooves are provided at pr...

no. 2 example

[0082] In the second embodiment, with Figure 1-4 The gate electrode 7a, the dummy gate electrodes 7b, 7c, and the first to third floating layers 3b-3d are connected to each other in a different manner compared to the device in .

[0083] Figure 5 A semiconductor device according to the second embodiment is shown. Image 6 for along Figure 11 The cross-sectional view of the device taken at the line VI-VI, Figure 7 for along Figure 11 A cross-sectional view of the device taken along line VII-VII, Figure 8 for along Figure 11 A cross-sectional view of the device taken along the line VIII-VIII, Figure 9 for along Figure 11 The cross-sectional view of the device taken at line IX-IX, while Figure 10 for along Figure 11 A cross-sectional view of the device taken along line X-X in . Figure 11 Not a cross-sectional view, but in Figure 11 Shading is drawn in to facilitate understanding of the drawings.

[0084] Such as Figure 5 As shown, the dummy gate electro...

no. 3 example

[0089] In the semiconductor device according to the third embodiment, the arrangement of the gate wiring 11, the first to third floating wirings 12-14, and the emitter electrode 15 is different from that according to the first and second embodiments.

[0090] Figure 12 A semiconductor device having the IGBT according to the present embodiment is shown. Figure 12 Not a cross-sectional view, but in Figure 12 Shading is partially drawn in the middle to facilitate understanding of the drawings. The first to third floating wirings are provided on both sides of the emitter electrode 15 so that they sandwich the emitter electrode 15 . Further, the gate wiring 11 is provided on both sides of the emitter electrode 15 and on the first to third floating wirings 12 - 14 such that the gate wiring 11 sandwiches the emitter electrode 15 and the first to third floating wirings 12 -14. The device also includes a gate pad 11a for connecting the gate wiring 11 and an external circuit, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com