Salad sauce powder

A salad dressing powder, glucose powder technology, applied in the application, food preparation, food science and other directions, can solve the problems of economic loss of manufacturers, threats to consumers' health, affecting product taste, etc., to improve oil holding capacity, good taste and Appearance, the effect of improving high temperature baking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

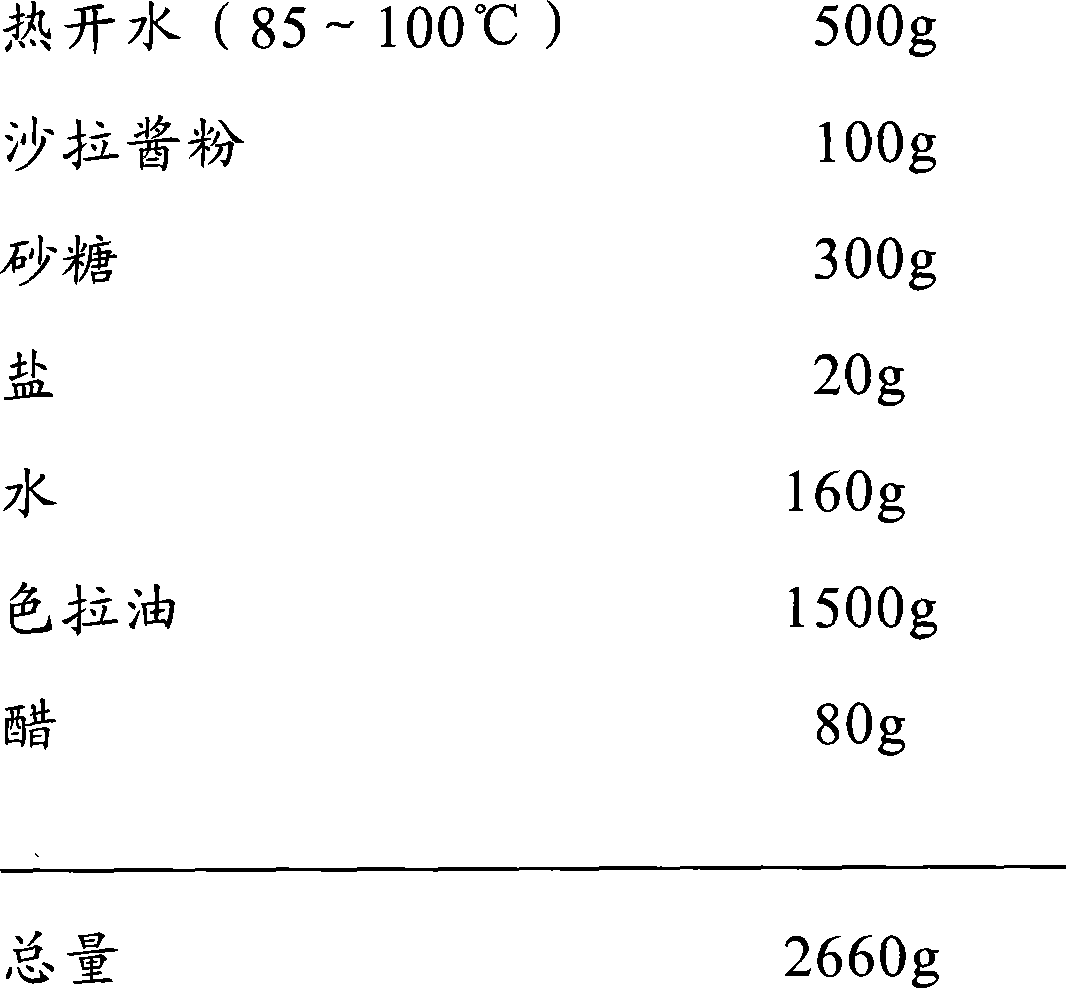

Image

Examples

Embodiment 1

[0068] Prepare raw materials according to the following weight percentages:

[0069] Dextrose Powder 16%

[0070] White sugar 10%

[0071] Acetylated Distarch Phosphate 40%

[0072] Starch acetate 10%

[0073] Sodium Carboxymethyl Cellulose 0.45%

[0074] Xanthan Gum 0.5%

[0075] Distilled Monoglyceride 1%

[0076] Sucrose Esters 1%

[0077] Polyglycerides 1%

[0078] Soy Protein 10%

[0079] Sodium Caseinate 10%

[0080] Potassium sorbate 0.05%

[0081] Wherein, the white granulated sugar is crushed and sieved through a 60-mesh sieve, and then the above-mentioned powders are mixed evenly.

Embodiment 2

[0083] Prepare raw materials according to the following weight percentages:

[0084] Glucose Powder 40%

[0085] White sugar 5.5%

[0086] Acetylated Distarch Phosphate 20%

[0087] Starch acetate 20%

[0088] Sodium Carboxymethyl Cellulose 0.25%

[0089] Xanthan Gum 0.25%

[0090] Distilled Monoglycerides 2.5%

[0091] Sucrose Esters 0.75%

[0092] Polyglycerol Esters 0.70%

[0093] Soy Protein 5%

[0094] Sodium Caseinate 5%

[0095] Potassium sorbate 0.05%

[0096] Wherein, the white granulated sugar is crushed and sieved through a 60-mesh sieve, and then the above-mentioned powders are mixed evenly.

Embodiment 3

[0098] Prepare raw materials according to the following weight percentages:

[0099] Dextrose Powder 24.5%

[0100] White sugar 10%

[0101] Acetylated Distarch Phosphate 25%

[0102] Starch acetate 25%

[0103] Sodium Carboxymethyl Cellulose 0.1%

[0104] Xanthan Gum 0.15%

[0105] Distilled Monoglycerides 4.2%

[0106] Sucrose Esters 0.5%

[0107] Polyglycerol Esters 0.5%

[0108] Soy Protein 5%

[0109] Sodium Caseinate 5%

[0110] Potassium sorbate 0.05%

[0111] Wherein, the white granulated sugar is crushed and sieved through a 60-mesh sieve, and then the above-mentioned powders are mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com