Kettle

A technology for boiling kettles and kettle bodies, which is applied to water boiling utensils, heating devices, and special materials for cooking utensils. control, high heat transfer rate, and the effect of utilizing electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

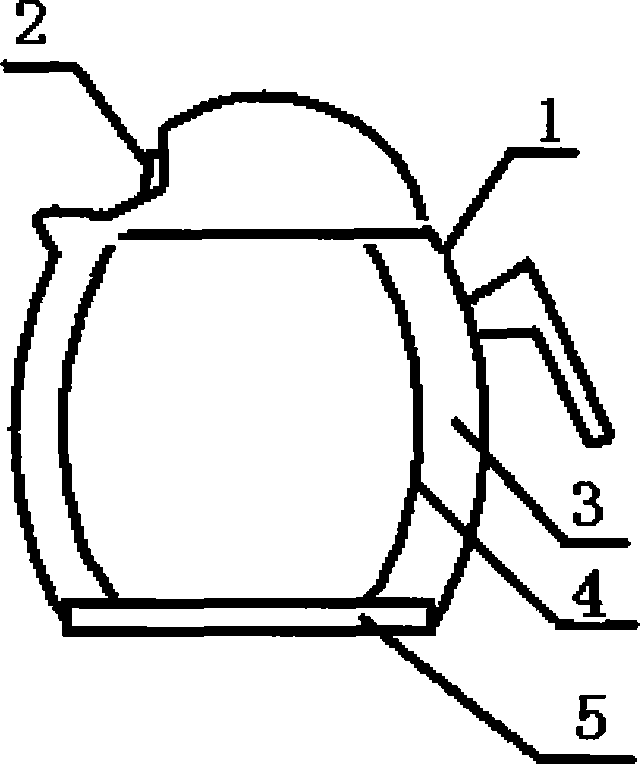

[0009] Below in conjunction with the accompanying drawings the present invention is further described: the heating element 2 of the kettle is made of carbon crystal material, and the carbon crystal heating element is installed at the bottom of the kettle, and the inner wall 4 of the kettle is made of carbon fiber composite glass material, and the outer wall 1 of the kettle is Stainless steel insulation layer, vacuum insulation layer 3 between the inner and outer walls of the kettle. When electric heating, carbon crystals quickly absorb heat and transfer heat to water to heat the water. The inner wall 4 of carbon fiber composite glass material can achieve long-term insulation performance.

[0010] Applying the present invention to the production of boiling kettles, utilizing the characteristics of heat insulation and heat preservation of carbon fiber and infrared heating of carbon crystals, it is applied to boiling kettles. Due to its high heat transfer rate and good heat preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com