Special-shaped blank continuous casting machine tundish and conversion method of different casting blank section thereof

A special-shaped billet continuous casting and tundish technology, which is applied to the tundish process field of special-shaped billet continuous casting in iron and steel metallurgy, can solve the problems of increasing the tundish cladding and the inability to convert the tundish, achieves fast construction, and solves the problem of sizing nozzles. The effect of steel penetration accident and reduction of production preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

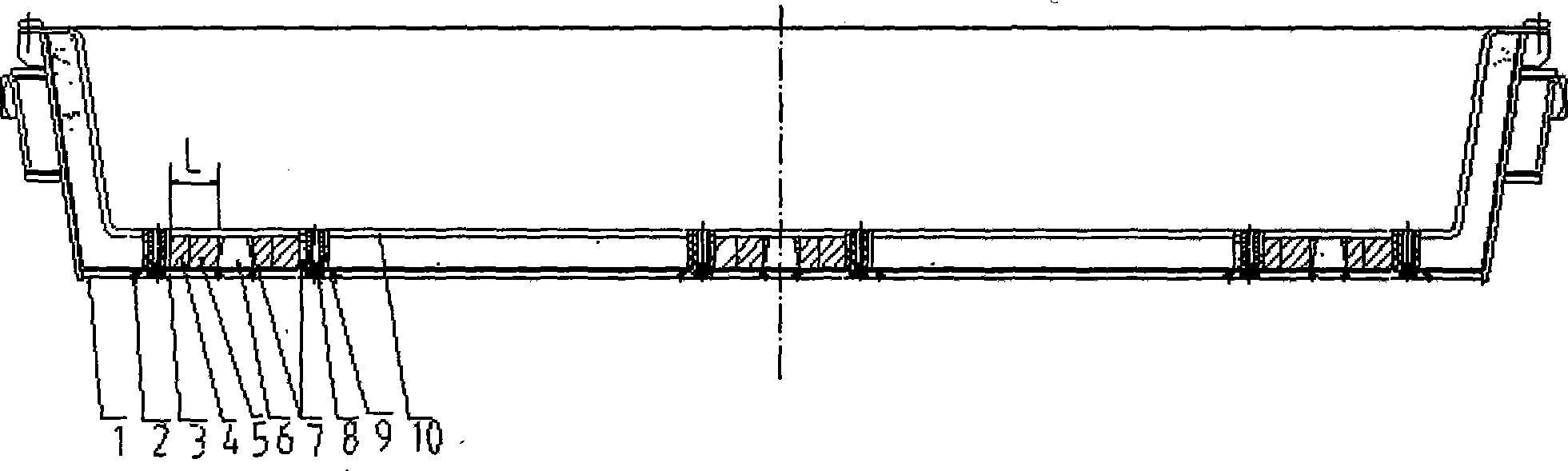

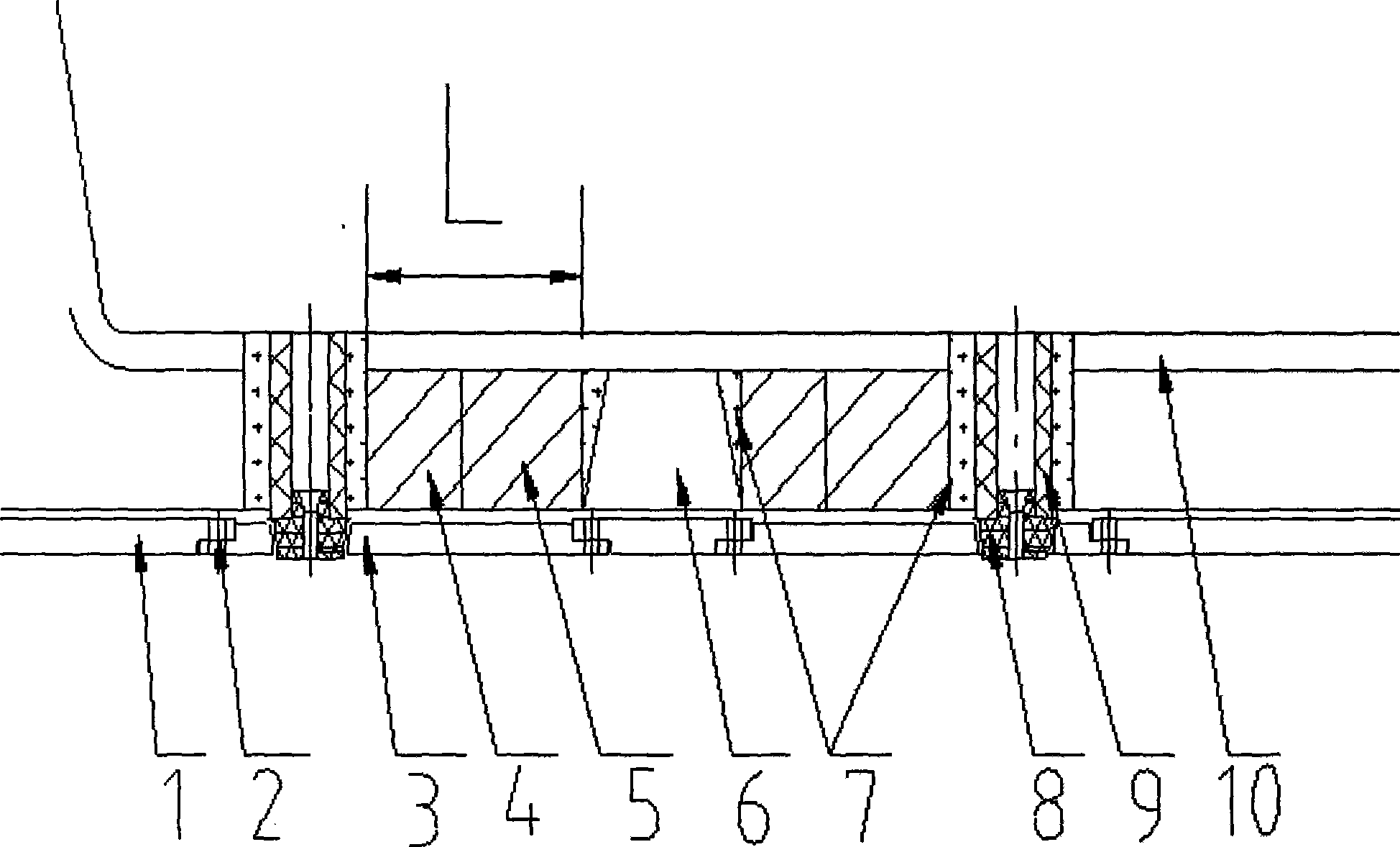

[0038] A continuous casting tundish for special-shaped slabs for different slab sections, comprising a tundish shell 1, a connecting plate 3, a magnesium prefabricated block, a tundish permanent lining 6, a sizing nozzle 8, a sizing nozzle seat brick 9, The working lining 10 of the tundish, the sizing nozzle 8 is installed and positioned through the sizing nozzle positioning hole 12 on the connecting plate 3, and the connecting plate 3 is fixedly connected to the cladding 1 with 8 M24 hexagonal bolts 2; the upper part of the sizing nozzle 8 is set Calibrated nozzle seat brick 9, two prefabricated blocks are installed in the space between the calibrated nozzle seat brick 9 and the permanent lining 6, the gap between the calibrated nozzle seat brick 9 and the tundish permanent lining 6 and the small magnesia prefabricated block and The gaps between the permanent linings 6 of the tundish are filled and compacted with magnesium ramming material 7 .

[0039] Through three combinati...

Embodiment 2

[0055] Other is with embodiment 1, and difference is:

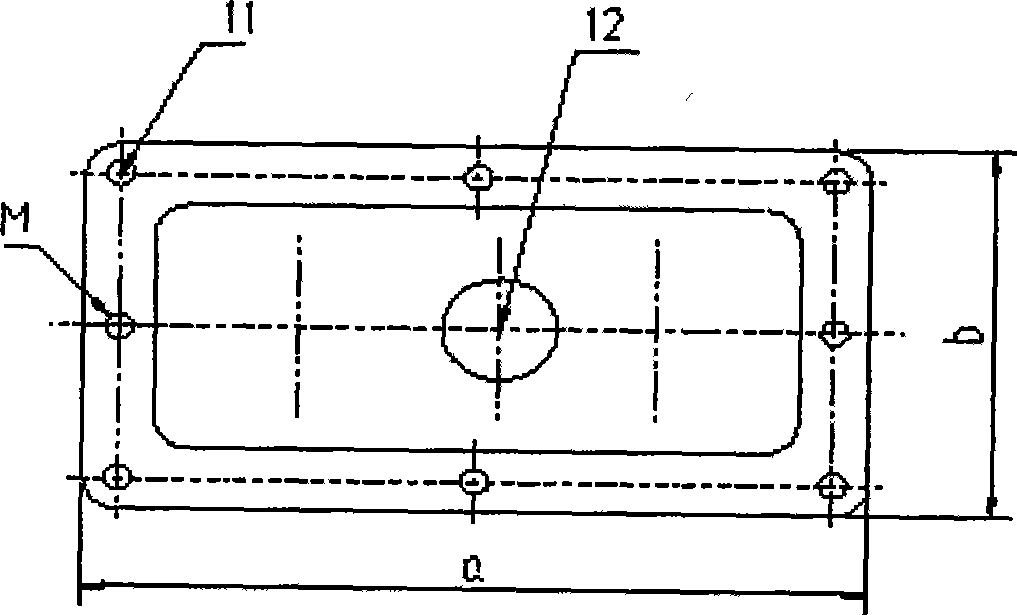

[0056] The connecting plate has a "convex" longitudinal section structure, a rectangular cross section, a length a of 360 mm, a width b of 250 mm, a total thickness c of 40 mm, and a "convex" platform thickness h of 25 mm. There is a positioning hole for the sizing nozzle on the top, the longitudinal section structure of the positioning hole is trapezoidal, the cross section shape is circular, the upper hole diameter R is 102mm, the lower hole diameter r is 92mm, and 8 M24 hexagonal bolt holes are designed around the lower part of the "convex" platform .

[0057] Each sizing nozzle adopts a connecting plate, and the distance between the two connecting plates is 150-180mm. The permanent lining is poured between the connecting plates, and each connecting plate is connected and fixed with the cladding by bolts.

[0058] The small magnesia prefabricated block 4 and the large magnesia prefabricated block 5 are composed of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com