Method for dissembling and processing waste and old circuit board for reuse of component

A technology for waste circuit boards and processing methods, applied in the fields of production, maintenance and waste recycling, can solve the problems of damage to chip reliability, plastic-packaged IC chip reliability damage, plastic-packaged IC chip delamination, etc., to avoid appearance size and The destruction of performance, the effect of ensuring reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

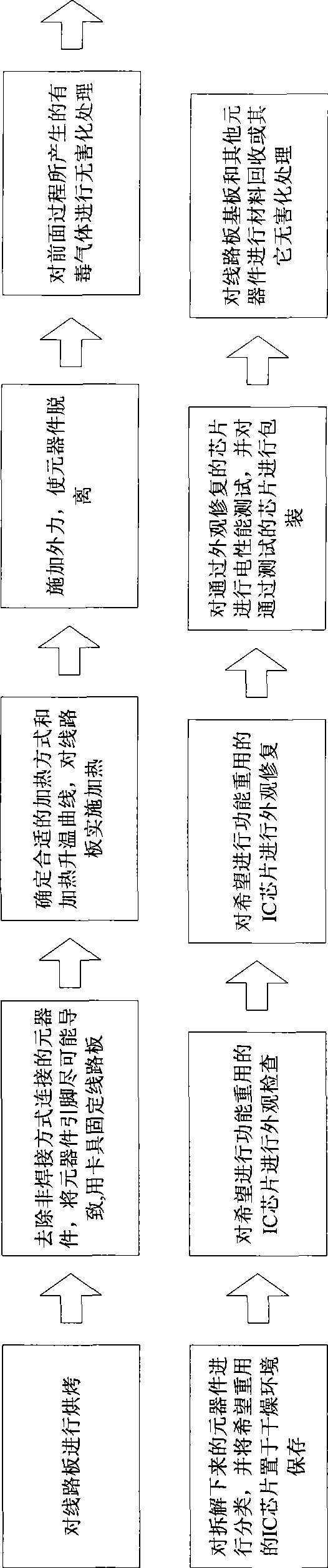

Method used

Image

Examples

Embodiment

[0044] Example: Disassembly process of a circuit board with components on one side

[0045]1) Take a piece of waste computer motherboard, on which there are a large number of aluminum electrolytic capacitors distributed, it is judged that it should be baked at low temperature, put it into a blast drying oven, put a desiccant in the drying oven, and set the temperature in the drying oven to 80 ℃, bake for 6 days, take out;

[0046] 2) Remove the components connected by non-welding methods such as buckle connection and thread connection on the circuit board, and guide the pins of the plug-in components to be removed on the circuit board as straight as possible so that they are basically perpendicular to the circuit board substrate, and use clamps Fixed circuit board;

[0047] 3) The circuit board is heated by infrared radiation and heat convection. The circuit board is gradually heated from room temperature to 150-160°C within 1.5-2 minutes and kept warm for 60s. Then, the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com