Remote-control device for carrier wave of electric welding machine

A technology of remote control device and electric welding machine, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of built-in battery of wireless remote control, special remote control cable required for wired remote control, large environmental interference, etc., to achieve power consumption Small, easy to install and use, good anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

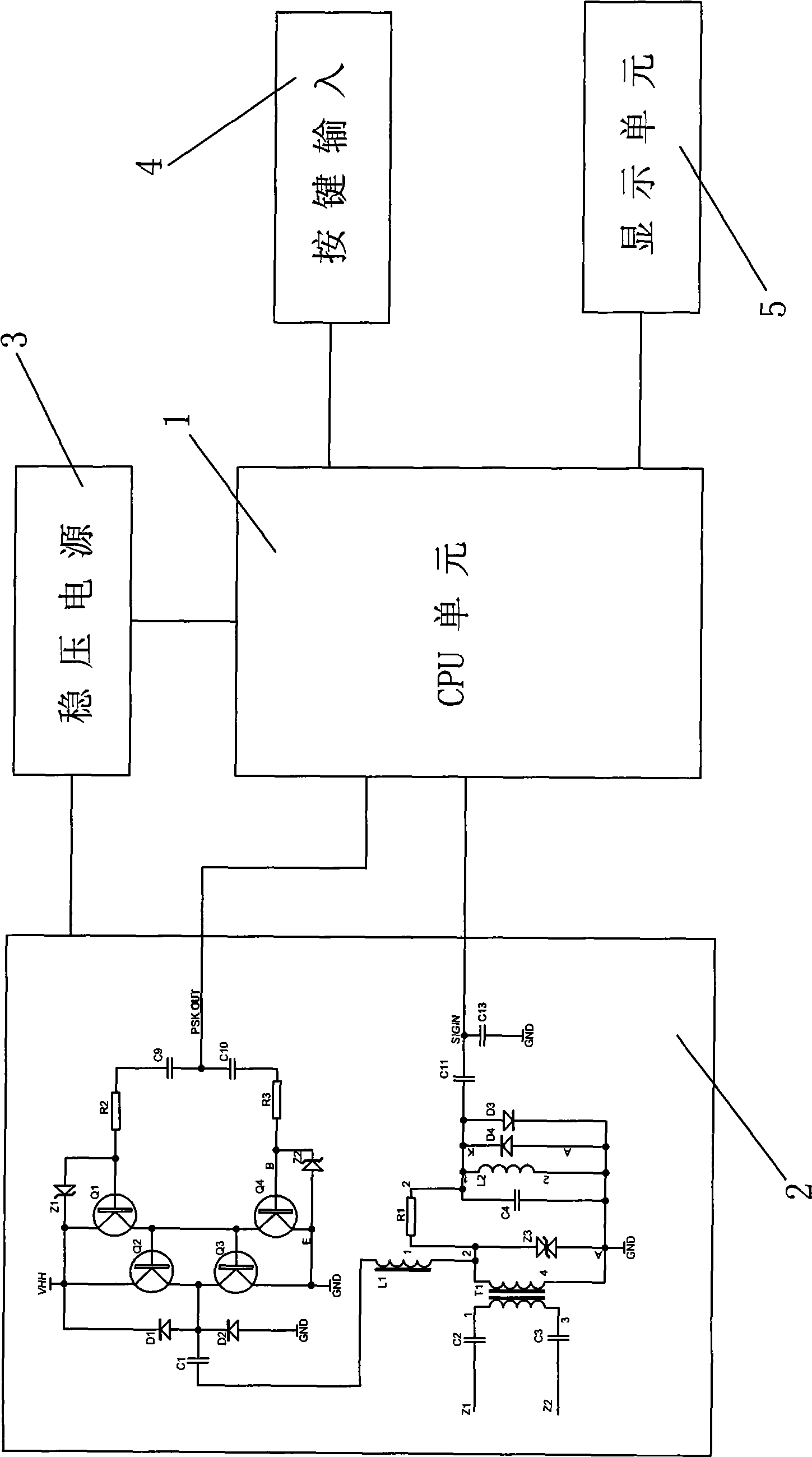

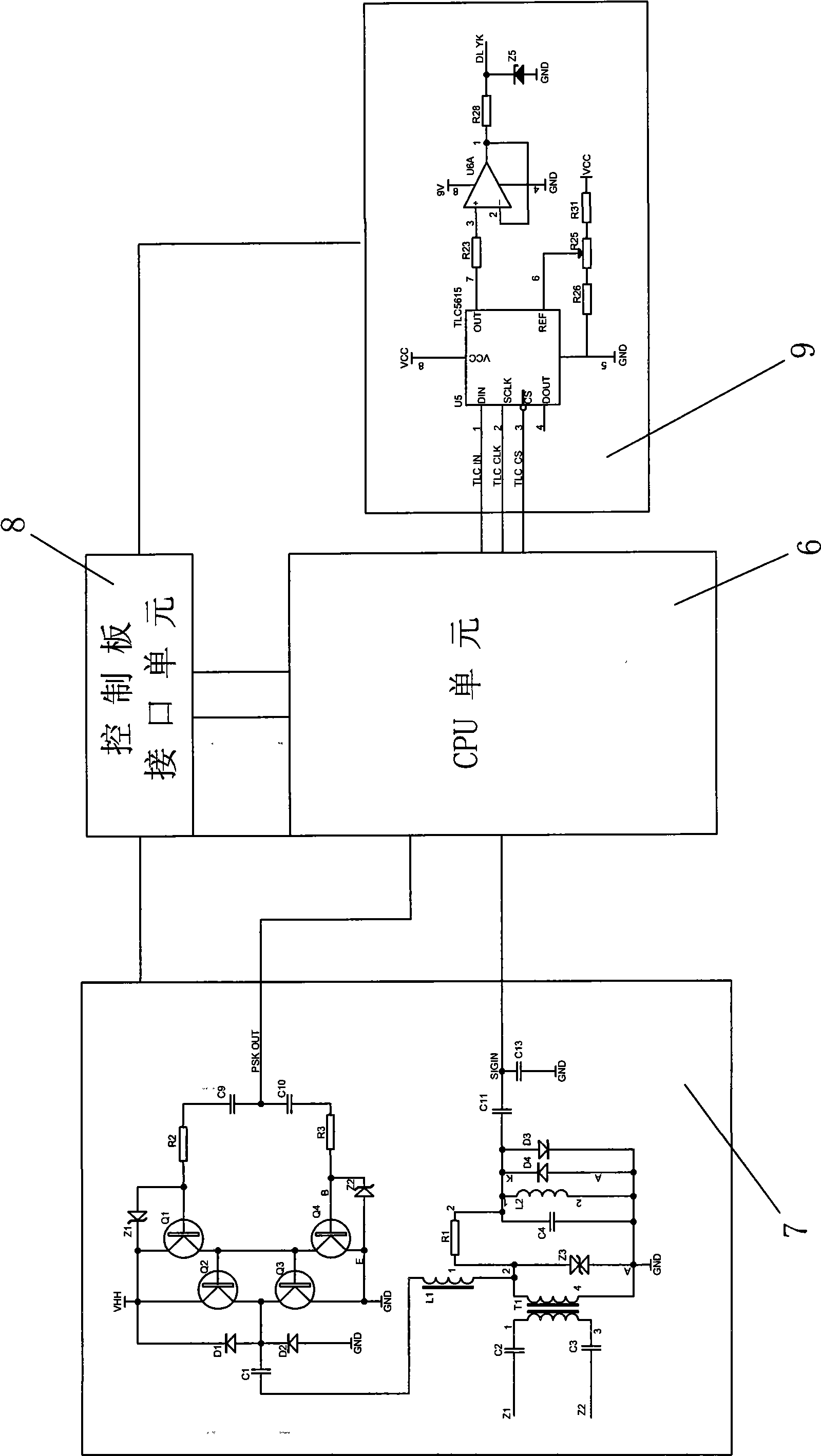

[0017] The invention is a carrier remote control device for an electric welding machine, which includes a main control board of the electric welding machine and a welding cable of the electric welding machine, and is characterized in that:

[0018] 1) There is a carrier wave remote control (hereinafter referred to as the remote control) of the electric welding machine, which is composed of a display unit, a key unit, a carrier transceiver drive unit, a regulated power supply unit, and a CPU unit with modulation and demodulation for setting , sending and receiving and displaying welding parameters, the two output connecting lines of the carrier sending and receiving drive unit of the remote control are connected with the welding clamp and the ground wire clamp of the welding cable of the electric welding machine,

[0019] 2) There is a carrier receiver (hereinafter referred to as the receiver) placed inside the welding machine, which is connected by a carrier transceiver drive u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com