Acoustic emission sensor

An acoustic emission sensor and preamplifier technology, which is applied in the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc. The effect of improving sensitivity, eliminating interference, and improving response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

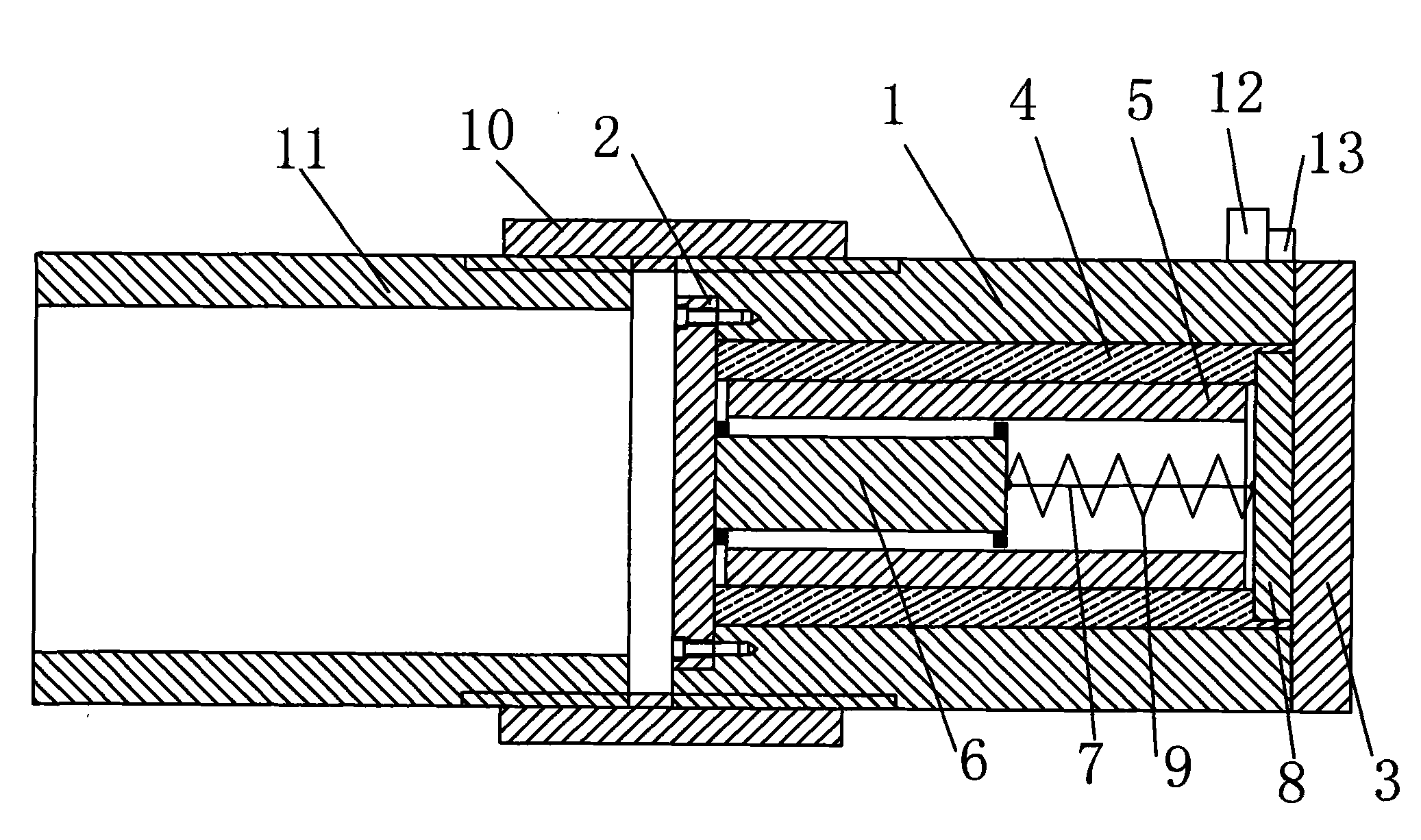

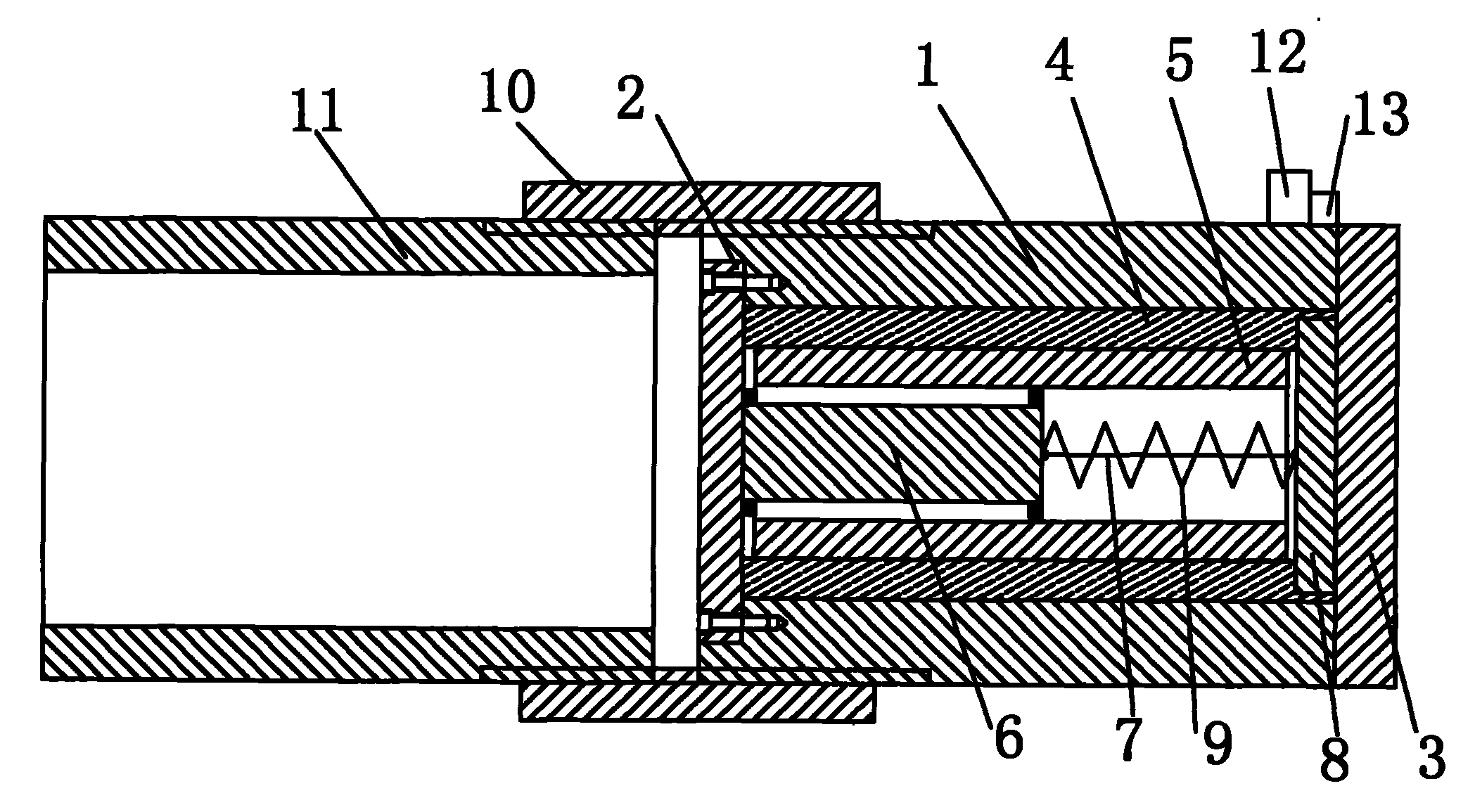

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] As shown in the figure, the acoustic emission sensor of the present invention includes a housing 1, a front cover 2, a rear cover 3, a filling sleeve 4, a piezoelectric element sleeve 5, a piezoelectric element 6, a wire 7, and a preamplifier 8 , Spring 9, connecting sleeve 10, fixing sleeve 11, power connector 12 and signal output terminal 13.

[0021] One end of the housing 1 is fixed with a front cover 2, and the housing 1 is a cylinder made of hard aluminum alloy. One end surface of the housing 1 has an annular groove along the center, and the front cover 2 is a circular thin plate whose diameter and thickness match the diameter and thickness of the groove on the end surface of the housing 1, that is, the front cover 2 Pressed in the groove, the plane of the front cover 2 and the end surface of the housing 1 are in the same horizontal plane. The front cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com