Hoisting mechanism for crane

A lifting mechanism and crane technology, applied in the direction of spring mechanism, hoisting device, etc., can solve problems such as low safety, safety accidents, and ignorance of the working status of the lifting mechanism, so as to ensure safety and avoid accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

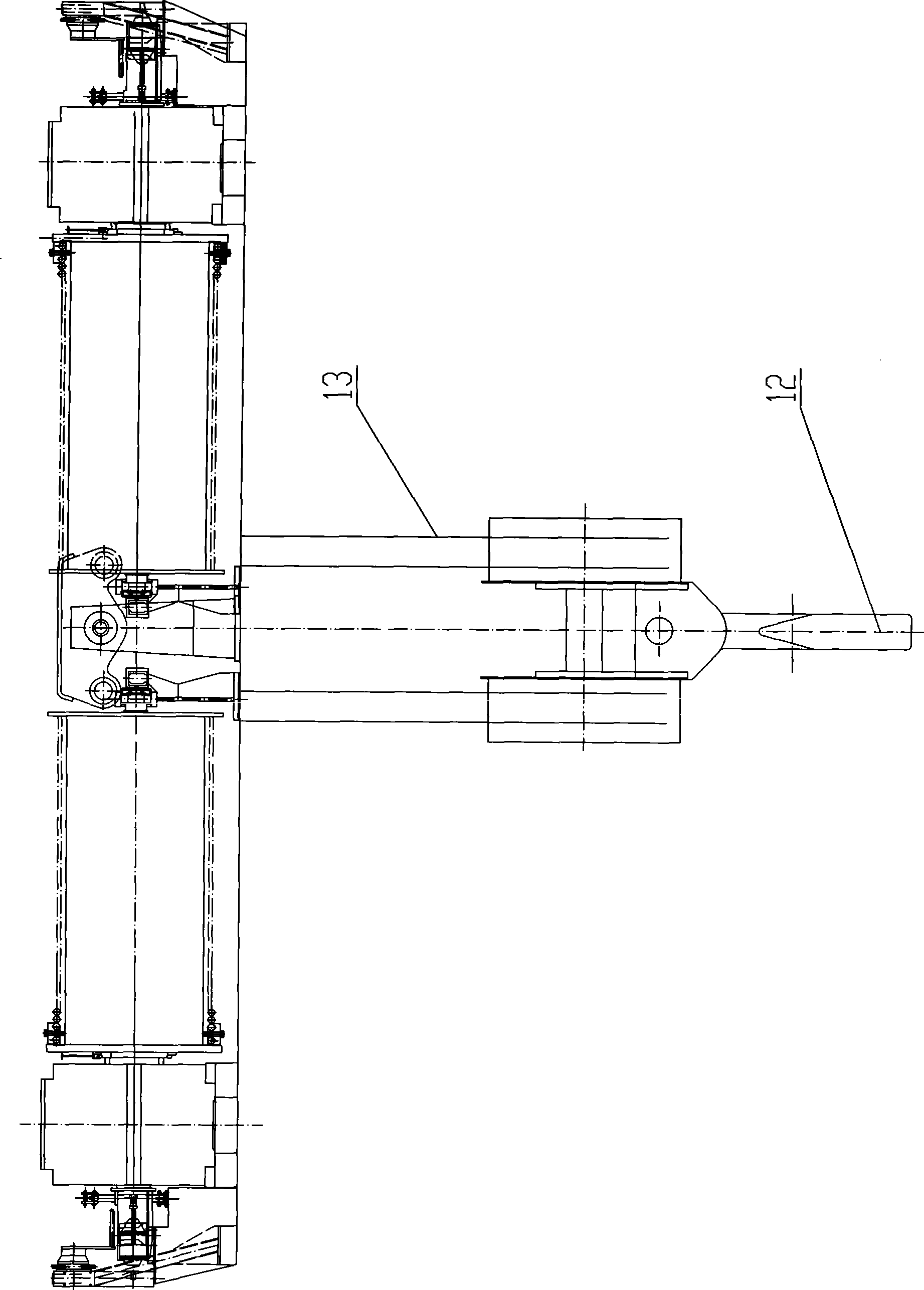

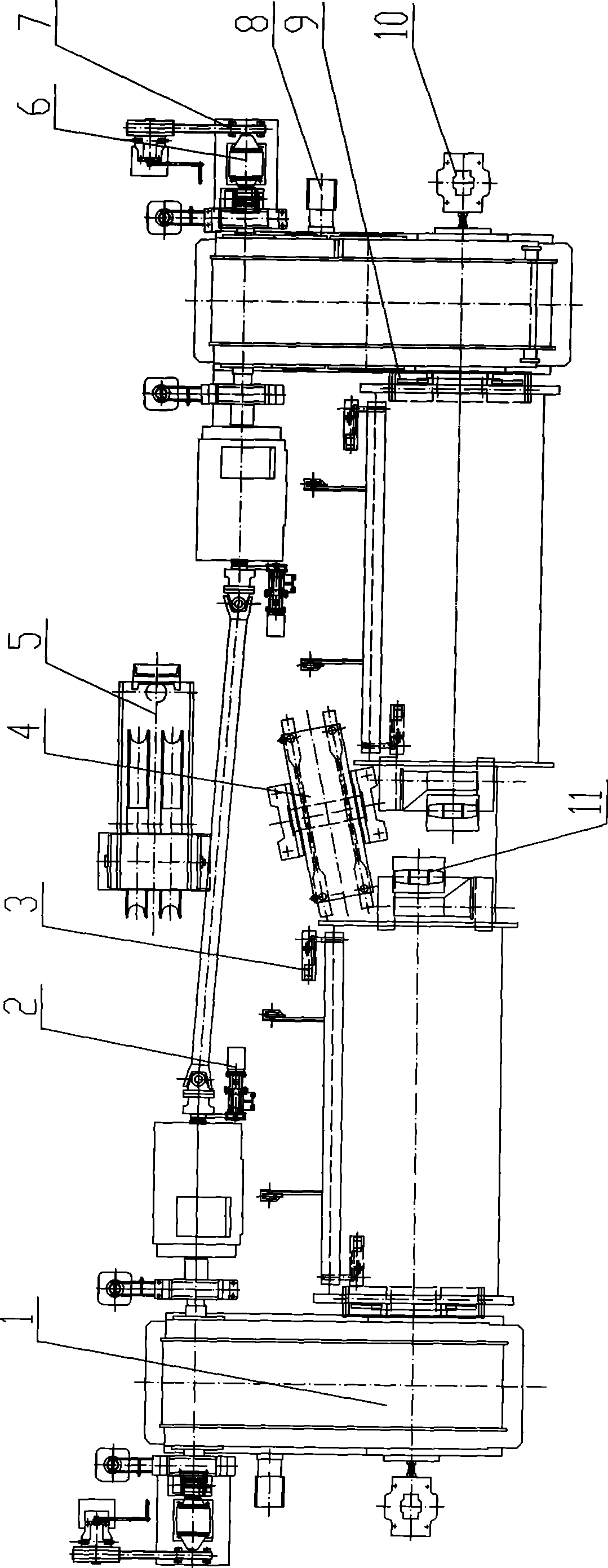

[0025] Such as figure 1 and figure 2 As shown, the present invention consists of a lifting drive system 1, a speed measuring device 2, a wire rope winding monitoring device 3, a balance beam device 4, a fixed pulley block assembly 5, a clutch device 6, a manual mechanism 7, an overspeed protection device 8, and a broken shaft protection device 9. Composed of a fire-off limiting device 10, a lifting limiting device 11, a hook pulley block 12, a wire rope 13 and other accessories.

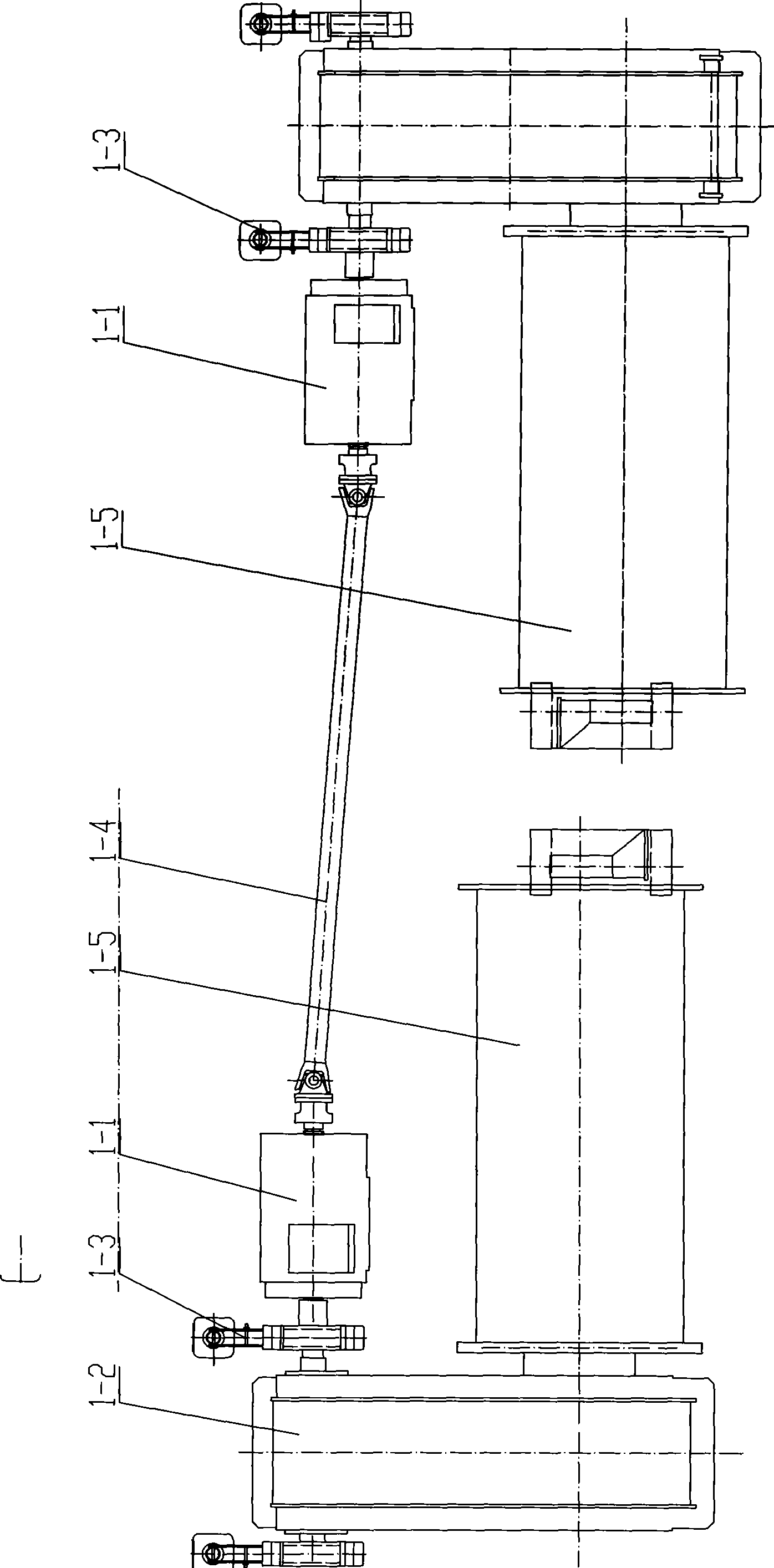

[0026] image 3 The middle lifting driving system 1 is composed of a motor 1-1, a speed reducer 1-2, a brake 1-3, a universal joint 1-4, a reel group 1-5 and the like.

[0027] The two motors are rigidly connected through the universal coupling 1-4, which ensures the synchronous rotation of the motors. The motor 1-1 drives the reel group 1-5 to rotate through the reducer 1-2. One end of two steel wire ropes 13 is fixed on the reel set 1-5, and the other end passes through the hook pulley set 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com