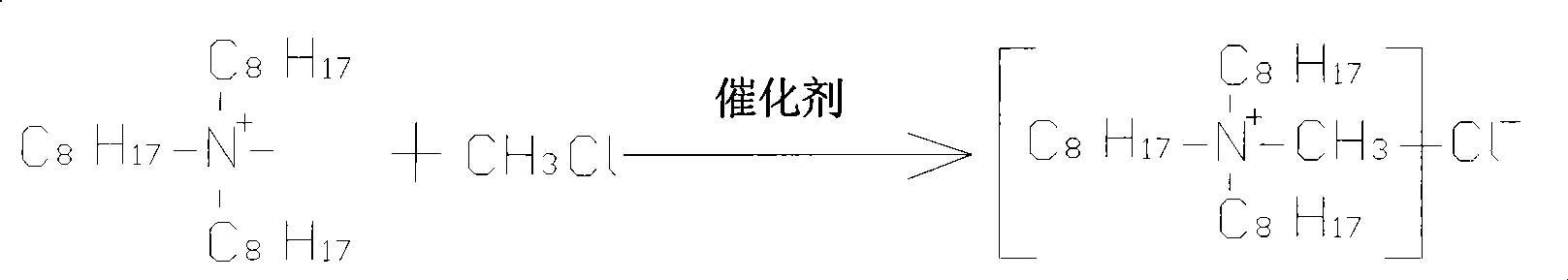

Production process of tri-n-octyl methyl ammonium chloride

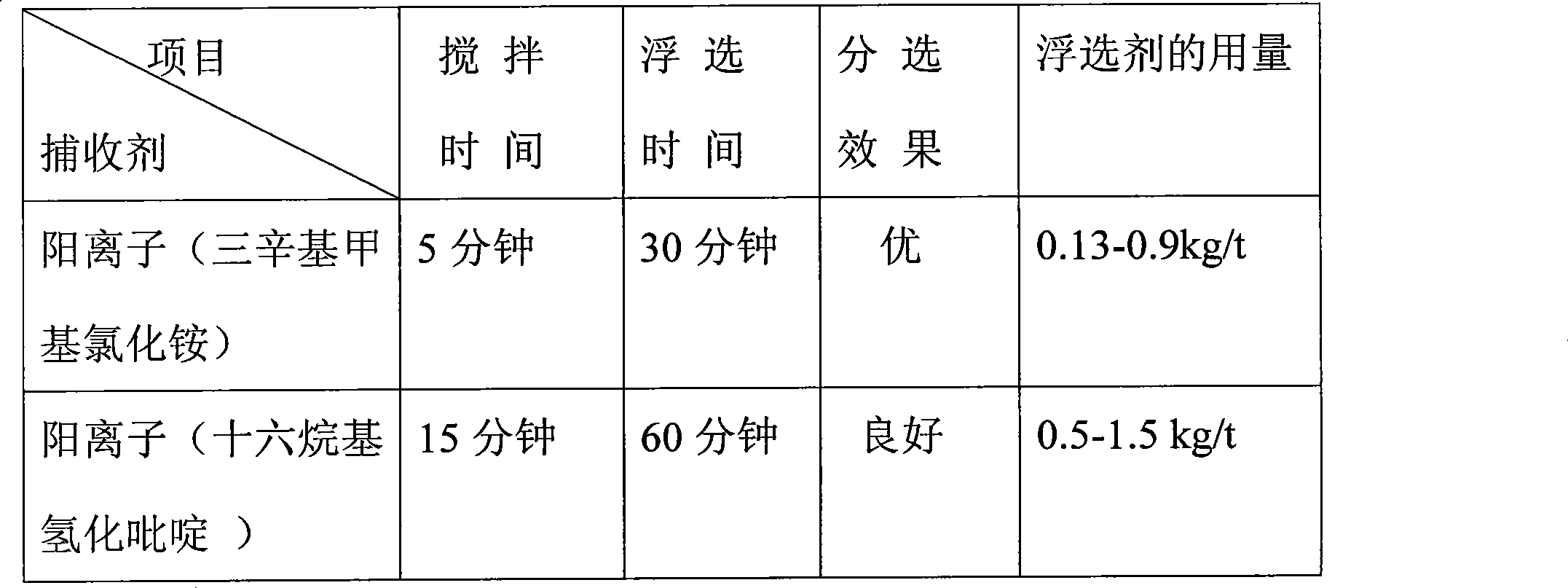

A technology of trioctylmethyl ammonium chloride and production process, which is applied in the production process field of trioctylmethyl ammonium chloride, and can solve the problem of limited production of trioctylmethyl ammonium chloride and poor separation effect Ideal, unable to meet the needs and other problems, to achieve the effect of good sorting effect, small footprint and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 3.01 moles of trioctylamine and 3.02 moles of methyl chloride in the ratio of 0.047 moles of basic catalyst: add 9.13 moles of industrial ethanol at a reaction temperature between 80-90°C, react for 10-12 hours, and keep warm for 1.5- 2.5 hours, and then evacuate and select temperature to generate finished product packaging, at this time analyze the specifications of the main product.

[0016] Appearance: light yellow transparent liquid, content 74.3%

[0017] PH value: 6.8, free amine: 1.7% The product is qualified

Embodiment 2

[0019] 3.17 moles of trioctylamine and 3.22 moles of methyl chloride in the ratio of 0.048 moles of basic catalyst: add 9.13 moles of industrial ethanol at a reaction temperature between 80-90°C, react for 10-12 hours, and keep warm for 1.5- 2.5 hours, and then evacuate and select temperature to generate finished product packaging, at this time analyze the specifications of the main product.

[0020] Appearance: light yellow transparent liquid, content 74.6%

[0021] PH value: 6.7, free amine: 1.8% The product is qualified

Embodiment 3

[0023] 3.33 moles of trioctylamine and 3.34 moles of methyl chloride in the ratio of 0.049 moles of basic catalyst: add 9.13 moles of industrial ethanol at a reaction temperature between 80-90°C, react for 10-12 hours, and keep warm for 1.5- 2.5 hours, and then evacuate and select temperature to generate finished product packaging, at this time analyze the specifications of the main product.

[0024] Appearance: light yellow transparent liquid, content 75.4%

[0025] PH value: 6.6, free amine: 1.6% The product is qualified.

[0026] Trioctyl ammonium chloride methyl (T811c) is a cationic surfactant, especially trioctyl methyl ammonium chloride, which is used as a collector and metal extractant for mineral raw materials, and as a phase transfer catalyst. High solubility in water, strong selectivity, insensitive to alkaline medium, and particularly good stability, corrosion resistance, non-toxic characteristics. As a flotation agent, trioctylmethylammonium chloride is especial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com