Technique for using leather products industrial waste as fuel

A technology of industrial waste and process method, applied in the field of process where industrial waste of leather products is used as fuel, can solve problems such as unfavorable environmental protection, achieve energy saving, significant economic and social benefits, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

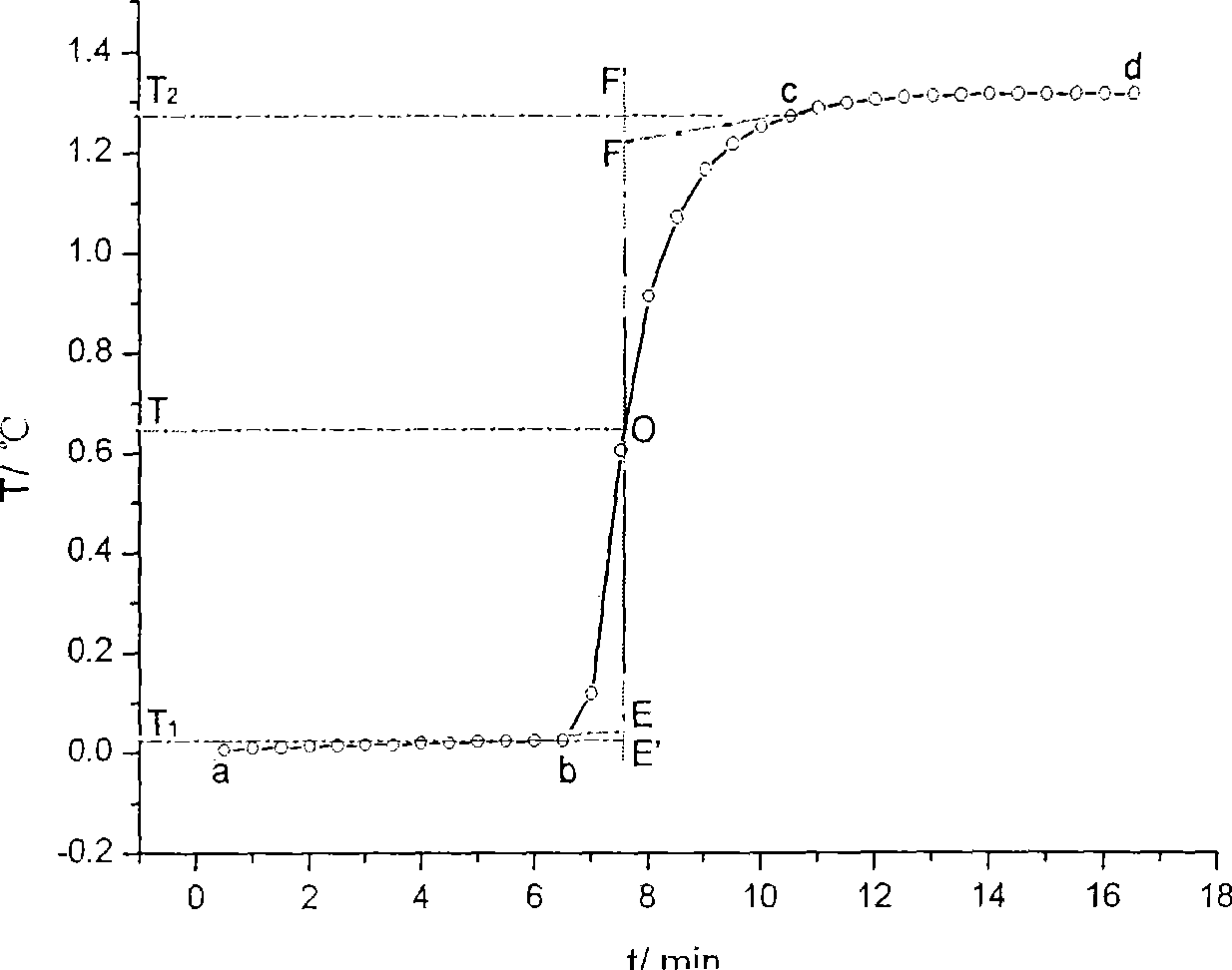

Image

Examples

Embodiment Construction

[0039] a. Put the industrial waste of leather products and coal into the pre-combustion zone of the industrial boiler according to the ratio of 1:1 and mix them to form a mixed fuel;

[0040] b. Combusting the above-mentioned mixed fuel in an industrial boiler. The industrial boiler includes a furnace body, which is divided into a pre-combustion zone, a combustion zone, and a burnout zone. The shell wall of the furnace body is composed of an inner wall and an outer shell, and a water clamp filled with circulating water set.

[0041] First, place the mixed fuel in the pre-combustion zone at a temperature of 550-650°C for anaerobic baking; then put the smoke generated after the mixed fuel is baked in the combustion zone for gasification at a temperature of 1150-1250°C ; Finally, the gasified flue gas is fully oxy-combusted in the burnout zone.

[0042] c. Use the heat recovery device to recover and convert the heat generated after incineration;

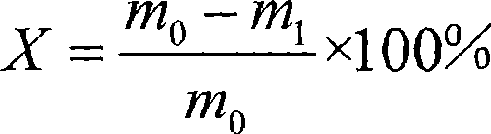

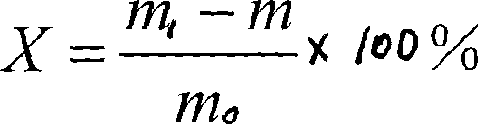

[0043] d. The chromium salt p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com