Preparation method of concentrated chicken-juice flavorings and flavorings produced using the method

A technology for seasoning and concentrating chicken, which is applied in the directions of food preparation, application, food science, etc., can solve the problems of ignoring the rich nutrition and low utilization efficiency of concentrated chicken juice, so as to improve the utilization rate of raw materials, ensure hygiene, and ensure simplicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

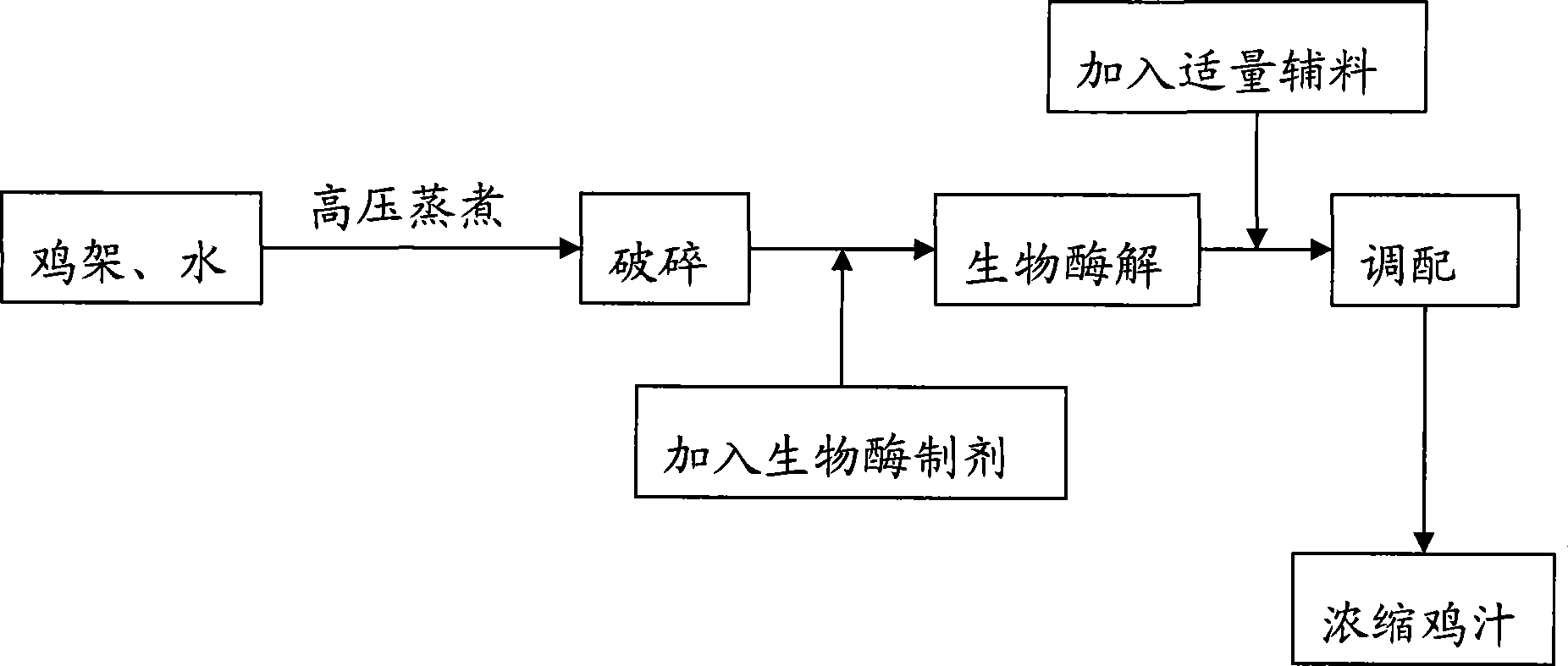

Method used

Image

Examples

Embodiment 1

[0028] Select 17kg of fresh and high-quality chicken frames, wash them and put them into a horizontal high-pressure cooking tank, add 35kg of water, cook them under high pressure at 0.15MPa for 30 minutes, and then use a crushing and beating machine to crush the cooked chicken frames into chicken bone slurry; Pour the chicken bone slurry into a jacketed pot that can scrape the sides and bottom, can be stirred, can display and control temperature, and can be dumped, and add 52g of high-efficiency and specific compound protease, including 39g of endonuclease and 13g of exopeptidase , then enzymatically hydrolyze the mud for 2.5 hours at 54°C and pH 6, and the Brix value (soluble solids) of the enzyme liquid quality control is 8% to 10%; Mesh and 100 mesh sieves are graded and filtered to remove bone grains, and the obtained filtrate is poured into a stirring and temperature-controllable batching tank, and 10% by weight of salt is added as an auxiliary material. The temperature is...

Embodiment 2

[0030] Select 18kg of fresh and high-quality chicken racks, wash them and put them into a horizontal high-pressure cooking tank, add 54kg of water, cook them under high pressure at 0.16MPa for 60min, and then use a crushing and beating machine to crush the cooked chicken racks into chicken bone slurry; Pour the chicken bone slurry into a jacketed pot that can scrape the sides and scrape the bottom, can be stirred, can display and control the temperature, and can be dumped, and add 210g of high-efficiency and specific compound protease, in which the ratio of endonuclease and exopeptidase is the same as above , then enzymatically hydrolyze the mud for 3.5 hours at 58°C and pH 7, and the Brix value (soluble solids) of the enzyme liquid quality control is 8% to 10%; the enzymolyzed mud is passed through 60 mesh, 80 Mesh and 100 mesh sieves to remove bone grains, then pour the obtained filtrate into a stirring and temperature-controllable batching tank, add 10% salt as an auxiliary ...

Embodiment 3

[0032] Select 20kg of fresh and high-quality chicken frames, wash them and put them into a horizontal high-pressure cooking tank, add 50kg of water, cook them under high pressure at 0.15MPa for 50min, and then use a crushing and beating machine to crush the cooked chicken frames into chicken bone slurry; Pour the chicken bone slurry into a jacketed pot that can be scraped and scraped, can be stirred, can display and control temperature, and can be poured, and add 140g of high-efficiency and specific compound protease, in which the ratio of endonuclease and exopeptidase is the same as above , then enzymatically hydrolyze the mud for 3 hours at 54°C and pH 6, and the Brix value (soluble solids) of the enzyme liquid quality control is 8% to 10%; pass the enzymatically hydrolyzed mud through 60 mesh and 80 mesh respectively , 100-mesh sieve to remove the bone grains, then pour the obtained filtrate into a stirring and temperature-controllable batching tank, add 10% salt as an auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com