Processing method for nano-pole forest

A processing method and nano-column technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems that it is difficult to control the high consistency of nanostructures, and the complexity of metal catalysts increases the process, so as to promote research and production development , Improve production efficiency and integration, reduce the effect of industrial production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

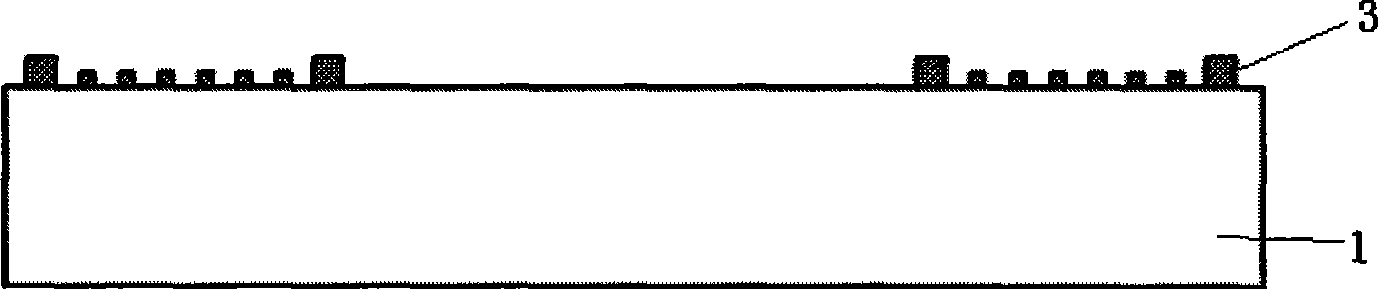

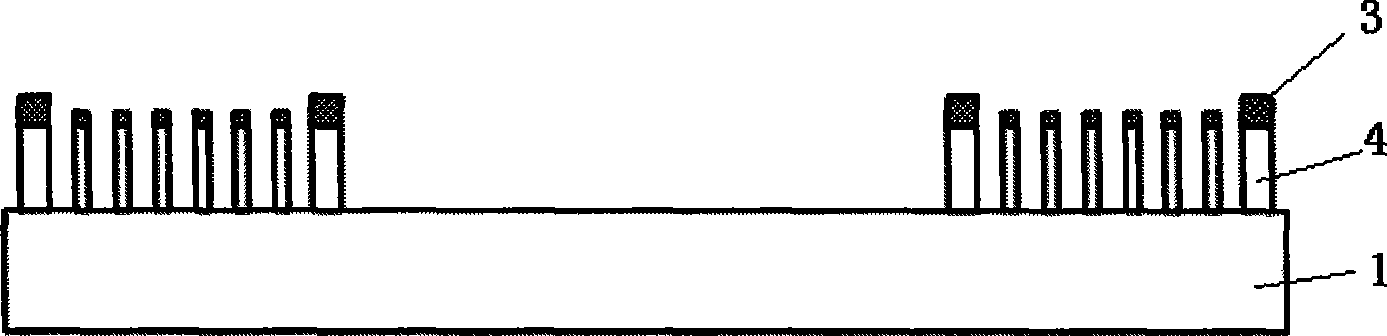

[0017] The invention utilizes the special physical and chemical properties of the oxygen plasma dry degumming process and the anisotropic dry etching technology in the traditional microelectronics process, and proposes a "bottom-up" and "top-down" nano Column Forest Parallel Processing Method.

[0018] Nano column forest parallel processing method of the present invention, its principle is:

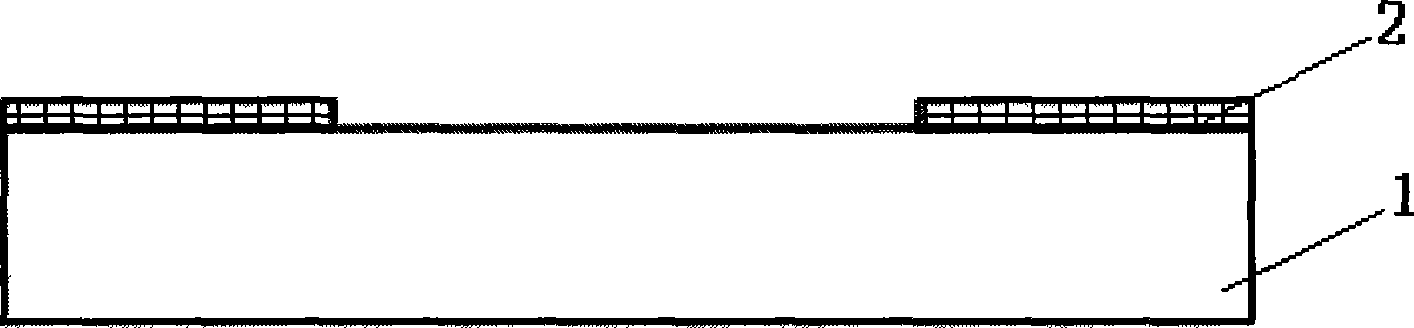

[0019] Such as figure 1 As shown, the photoresist 2 is spin-coated on the surface of the substrate 1, and then the photoresist is exposed by conventional optical lithography equipment, and the photoresist 2 is developed using a corresponding developer to remove the excess photoresist 2, On the substrate 1, only the pattern of the photoresist 2 at the position of the predesigned nano-pillar forest is left, that is, the shape corresponding to the nano-pillar forest....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com