Gasifying device for liquid fuel or solid fuel aqueous slurry

A solid fuel and gasification device technology, which is applied in the direction of granular/powdered fuel gasification, joint combustion relief, and production of combustible gas, which can solve the problem of difficult and accurate measurement of coal powder, increase cycle gas compression work consumption, and gasification reaction It is difficult to increase the pressure and other problems, so as to achieve uniform gas residence time, improve sensible heat utilization efficiency, and improve coal gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

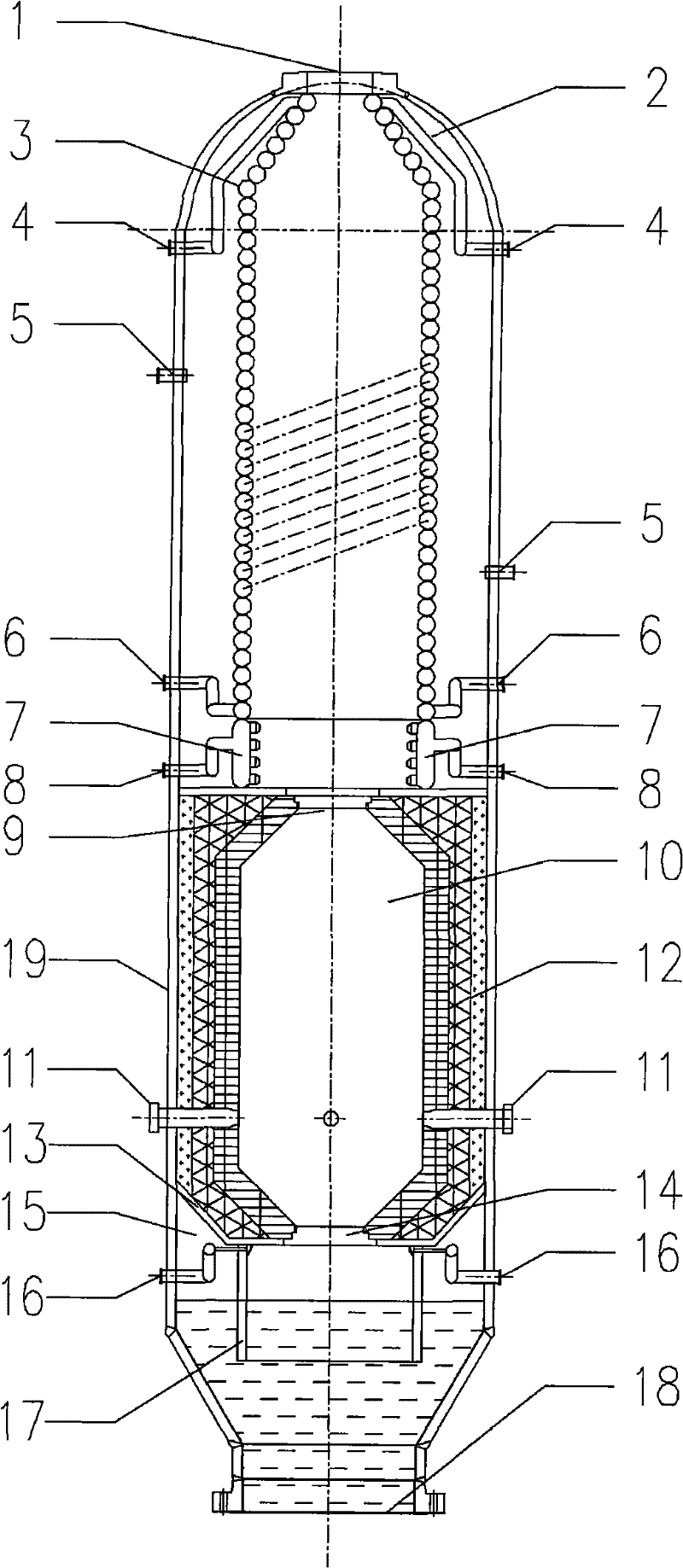

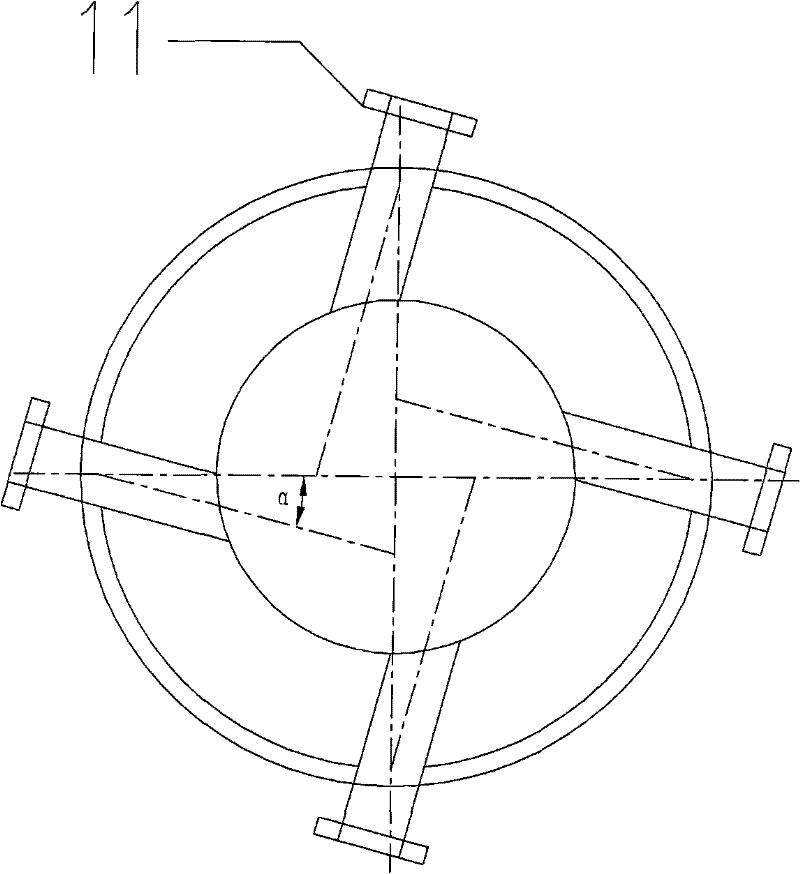

[0027] like figure 1 As shown, a gasification device for liquid fuel or solid fuel water slurry, the gasification furnace shell 19 of the gasification device is an upright cylinder, and the internal structure of the gasification furnace shell 19 is divided into three sections, from top to bottom The gas cooling chamber 2 , the gasification chamber 10 and the slag collection chamber 15 are respectively connected in the lower gasification furnace shell 19 coaxially.

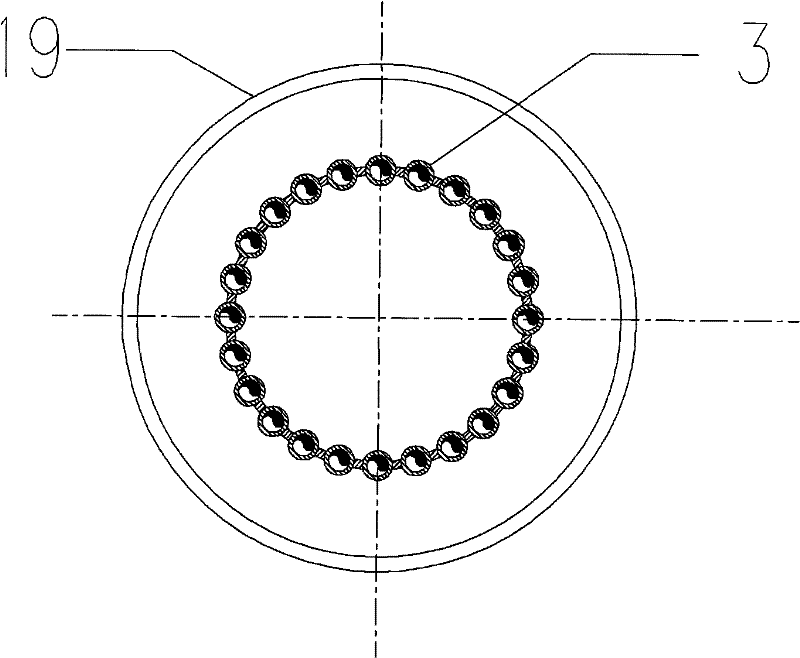

[0028] A water-cooled wall boiler 3 is installed in the gas cooling chamber 2, and the water-cooled wall boiler 3 can adopt coiled tubes or vertical bundled tubes or water jackets.figure 1 is the case where the water-cooled wall boiler 3 adopts coiled tubes, image 3 This is the case where the water-cooled boiler 3 adopts vertical bundled tubes, and the tubes are connected by welding, such as Figure 4~5 as shown, Image 6 This is the case where the water-cooled wall boiler 3 adopts a water jacket. The upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com