Bisamide quaternary ammonium salt sheet softening agent, preparation and uses thereof

A quaternary ammonium salt and softener technology, which is applied in the field of bisamide quaternary ammonium salt paper softener and its preparation, can solve the problems of poor water absorption of paper, and achieve the effects of speeding up the speed, shortening the reaction time, and easily obtaining raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

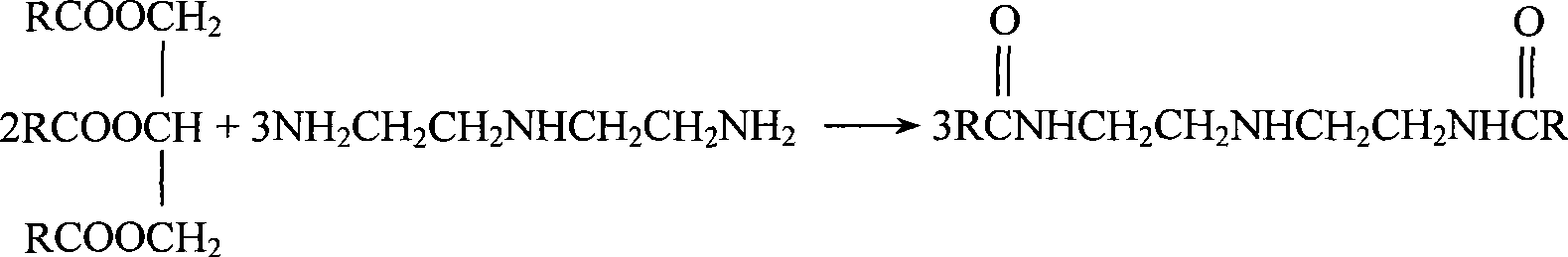

Method used

Image

Examples

Embodiment 1

[0022] Add 130 g of glyceryl stearate into a three-necked flask equipped with a stirrer and a thermometer, heat to 60° C. to dissolve, add a p-toluenesulfonic acid catalyst accounting for 1.2% of the mass fraction of the raw material, and stir at a speed of 120 r / min. After the temperature was raised to 130°C, 33g of diethylenetriamine was added dropwise. After the dropwise addition of diethylenetriamine, the temperature was gradually raised to 150°C, and the temperature was kept for 2.5 hours. The water was separated by a water separator to obtain an intermediate.

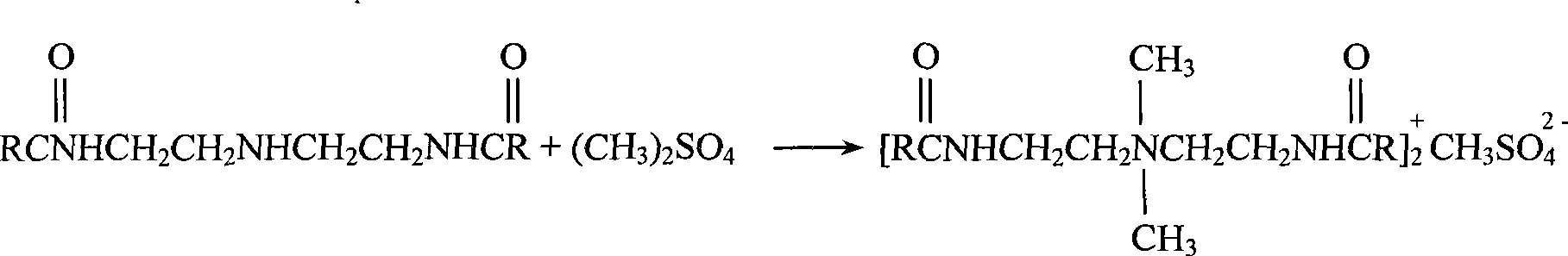

[0023] Put 146g of the obtained intermediate into a three-necked flask, and raise the temperature to 95°C; gradually add 32g of dimethyl sulfate dropwise, keep it warm for 1 hour, and cool down to obtain a light yellow block product, which is the bisamide quaternary ammonium salt paper softener .

[0024] The appearance of the softener is a light beige paste solid with a special smell, and the cationic degree is 0...

Embodiment 2

[0026] Add 150g of glyceryl stearate into a three-necked flask equipped with a stirrer and a thermometer, heat to 60°C to dissolve, add a p-toluenesulfonic acid catalyst accounting for 1.4% of the mass fraction of the raw material, stir and heat up to 130°C, drop Add 44g of diethylenetriamine, after the dropwise addition of diethylenetriamine, gradually raise the temperature to 150°C, and keep it warm for 2 hours; pass through a water separator to separate water to obtain an intermediate.

[0027] Put 173g of the above-mentioned intermediate into a three-necked flask, and heat up to 95°C; gradually add 39g of dimethyl sulfate dropwise, keep the temperature for 1.5h, and cool the discharge to obtain a light yellow block product, which is the soft bisamide quaternary ammonium salt paper agent.

[0028] The appearance of the softener is a light beige paste solid with a special smell and a cationic degree of 0.6.

Embodiment 3

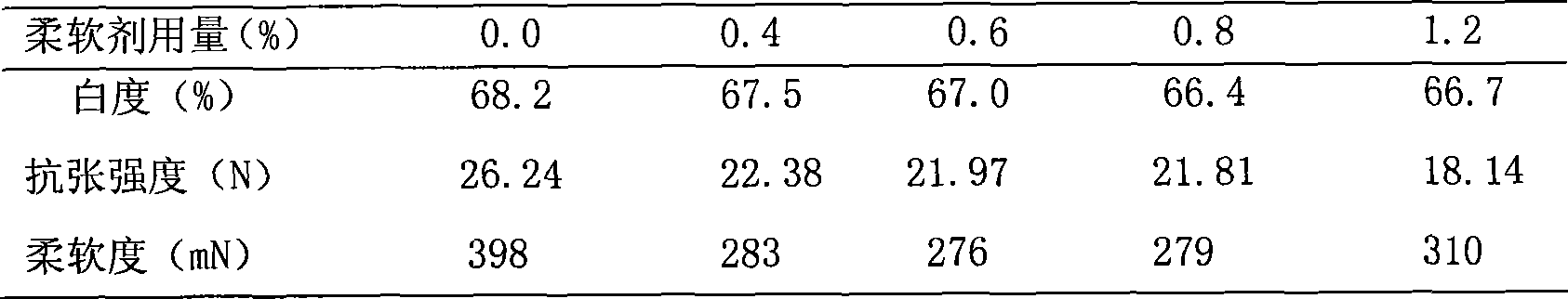

[0030] Application of bisamide quaternary ammonium salt paper softener

[0031] The pulp used in the papermaking experiment was 100% bleached wheat straw pulp provided by a paper mill, with a beating degree of 30°SR. Before the experiment, it was simply sieved to remove impurities such as pulp and slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com