Method for optimizing operating parameter of frequency control drive system of direct air cooling blower fan

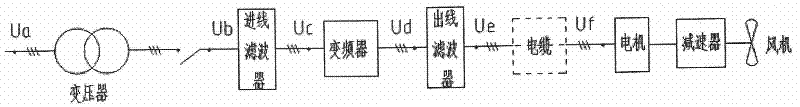

A technology of frequency conversion speed regulation and operation parameters, which is applied in the direction of machine/engine, mechanical equipment, non-variable capacity pump, etc., can solve the problem that the output torque of the motor cannot meet the design and operation requirements, cables, motor burning loss, large operating current, etc. problems, to achieve the effect of increasing the system power supply voltage, improving the operation stability, and reducing the load pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Some parameters of the direct air-cooled variable frequency speed regulation drive system of a power plant are as follows:

[0050] Motor (imported brand) technical parameters:

[0051] Rated power: Ped=110KW

[0052] Rated voltage: Ued=380VAC

[0053] Rated current: Ied=205A

[0054] Rated torque: T N =1051Nm

[0055] Rated speed: n ed =991rpm

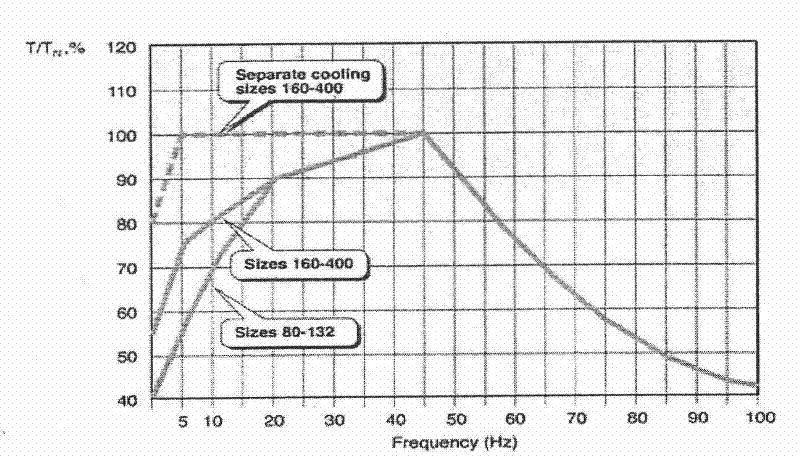

[0056] During the high temperature season in summer, the ambient temperature is high (≥35°C), the output of the air cooling system is insufficient, and the cooling effect is not good, which will lead to high back pressure of the steam turbine unit and threaten the normal operation of the unit.

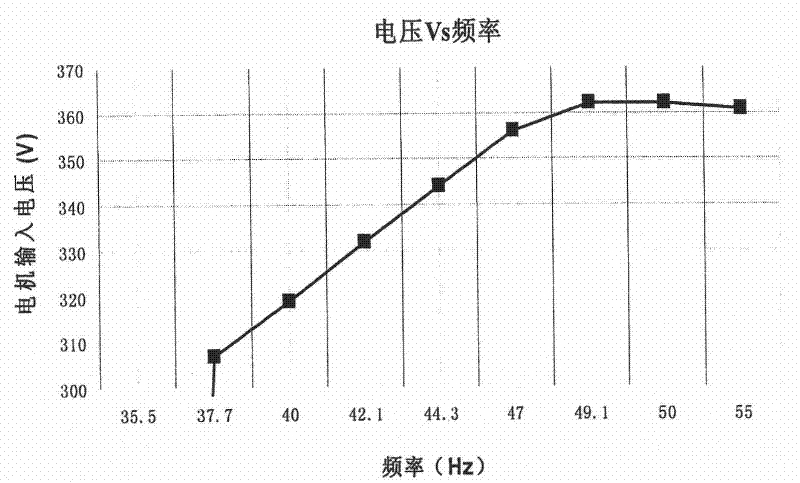

[0057] The normal operation parameter adjustment method is as follows (only considering the frequency converter):

[0058] Adjust the output frequency of the inverter to 55Hz, and the fan runs at 110% speed to improve the cooling effect.

[0059]In this state, the motor is running at constant power. Since the input voltage Uf of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com