Polarization dual wavelength fiber-optical ultrashort pulse laser

An ultrashort pulse and fiber laser technology, applied in the field of optical information, can solve the problems of difficult to achieve passive mode-locked ultrashort laser pulse, small adjustment range, small spectral interval, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

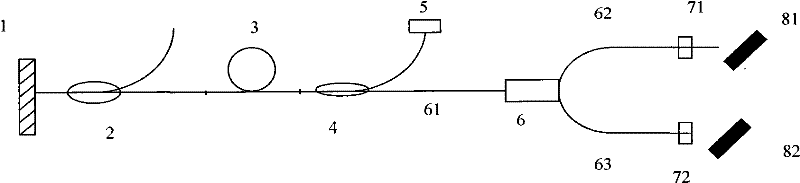

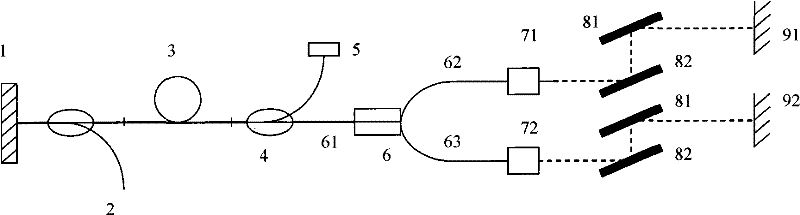

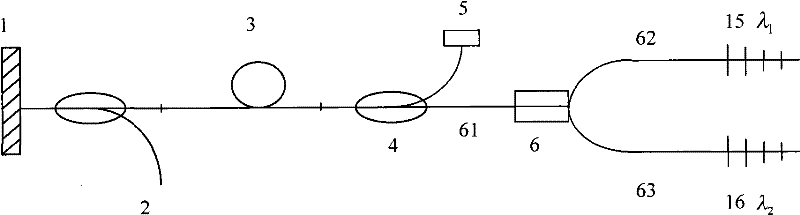

[0076] The cavity structure of a polarized dual-wavelength fiber ultrashort pulse laser provided in this embodiment adopts a section of polarization-maintaining rare-earth-doped gain fiber as the gain medium, and uses a polarization beam splitter (PBS) to separate laser beams with two different polarization directions As a long wave (λ 1 ) and shortwave (λ 2 ) laser oscillation tuning arm, the rare earth-doped fiber is doped with rare earth element Nd 3+ 、Pr 3+ , Yb 3+ 、Er 3+ and Tm 3+ Optical fiber; the optical fiber is one of ordinary single-mode polarization-maintaining rare-earth-doped optical fiber, multi-layer pumped rare-earth-doped large-core single-mode polarization-maintaining optical fiber or rare-earth-doped polarization-maintaining large-core single-mode photonic crystal optical fiber. Please refer to the attached Figure 1 to Figure 5 .

[0077] See attached figure 1 , the first cavity shape is to directly use a grating as a dual-wavelength laser cavity t...

Embodiment 2

[0083] The cavity structure of a polarization dual-wavelength fiber ultrashort pulse laser provided in this embodiment is to use a polarization beam splitter (PBS) to separate the light of two different polarization directions into long-wave (λ 1 ) and shortwave (λ 2 ) of the laser oscillation tuning arm, using two polarization-maintaining doped rare-earth fibers with different lengths, and the two dual-wavelength laser tuning arms as gain media. Rare earth doped fiber is doped with rare earth element Nd 3+ 、Pr 3+ , Yb 3+ 、Er 3+ and Tm 3+ Optical fiber; the optical fiber is one of ordinary single-mode polarization-maintaining rare-earth-doped optical fiber, multi-layer pumped rare-earth-doped large-core single-mode polarization-maintaining optical fiber or rare-earth-doped polarization-maintaining large-core single-mode photonic crystal optical fiber. Please refer to the attached Figure 6 ~ Figure 10 .

[0084] See attached Image 6 , the first cavity structure is: th...

Embodiment 3

[0090] The cavity structure of a polarized dual-wavelength fiber ultrashort pulse laser provided in this embodiment is characterized in that a section of rare earth-doped non-polarization-maintaining gain fiber is used as the gain medium, and a polarization beam splitter (PBS) divides two different The laser light in the polarization direction is regarded as the long wave (λ 1 ) and shortwave (λ 2 ) laser oscillation tuning arm. Rare earth doped fiber is doped with rare earth element Nd 3+ 、Pr 3+ , Yb 3+ 、Er 3+ and Tm 3+ Optical fiber; the optical fiber is an ordinary single-mode non-polarization-maintaining rare-earth-doped optical fiber, a multi-layer pumped rare-earth-doped large-core single-mode non-polarization-maintaining optical fiber or a rare-earth-doped non-polarization-maintaining large-core single-mode photonic crystal fiber A sort of. Please refer to the attached Figure 11 ~ Figure 12 .

[0091] See attached Figure 11 , the cavity of the first structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com