Method for producing gas hydrate and device thereof

A gas hydrate and production device technology, applied in the direction of using atmospheric pressure to chemically change substances, chemical methods for reacting liquids and gaseous media, chemical instruments and methods, etc., can solve problems that do not involve gas hydrate Problems such as rapid and continuous production equipment and production process, low gas storage density of hydrate, complex operation process and equipment, etc., can save storage and transportation costs, improve gas separation efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

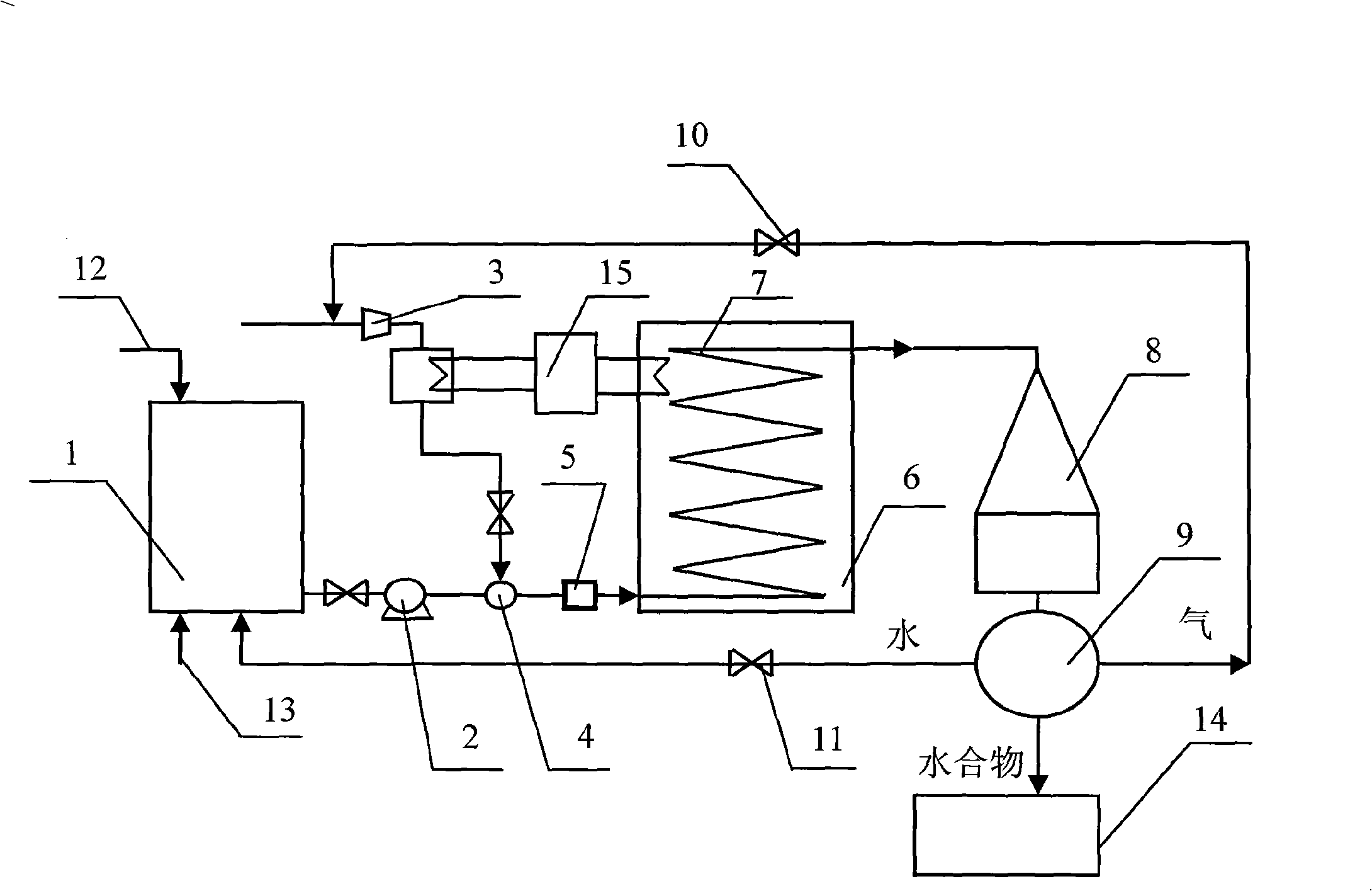

[0015] The gas hydrate production device adopted in the present invention is as figure 1 As shown, all parts of the device are insulated with thermal insulation materials. Water has a volume of 0.54m 3 The low temperature water tank 1 is kept at a temperature of 1-5°C, and an appropriate amount of hydrate formation accelerator is added through the dosing pipe 12. The accelerator consists of 5% cyclopentane and dodecylbenzenesulfonate with a concentration of 1200ppm in the total solution mass fraction. Sodium acid is prepared, and the mixture solution is called "rich water". The "rich water" is boosted to 8MPa with the booster pump 2, and the flow rate is 0.7L / min. The natural gas cooled to 2°C is mixed with the "rich water" at a molar ratio of 1:100 through the gas-liquid mixer 4. The bubble-like gas-liquid two-phase flow is formed through the spiral bubble generator 5, which increases the gas-liquid contact area and accelerates mass transfer. The ascending spiral coil pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com