Deformable aerofoil cover with changeable rigidity

A variable stiffness and skin technology, applied in the aerospace field, can solve the problems of poor skin's ability to receive aerodynamic loads, low overall wing carrying capacity, etc., to achieve high overall carrying capacity, improve various performance, and low requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

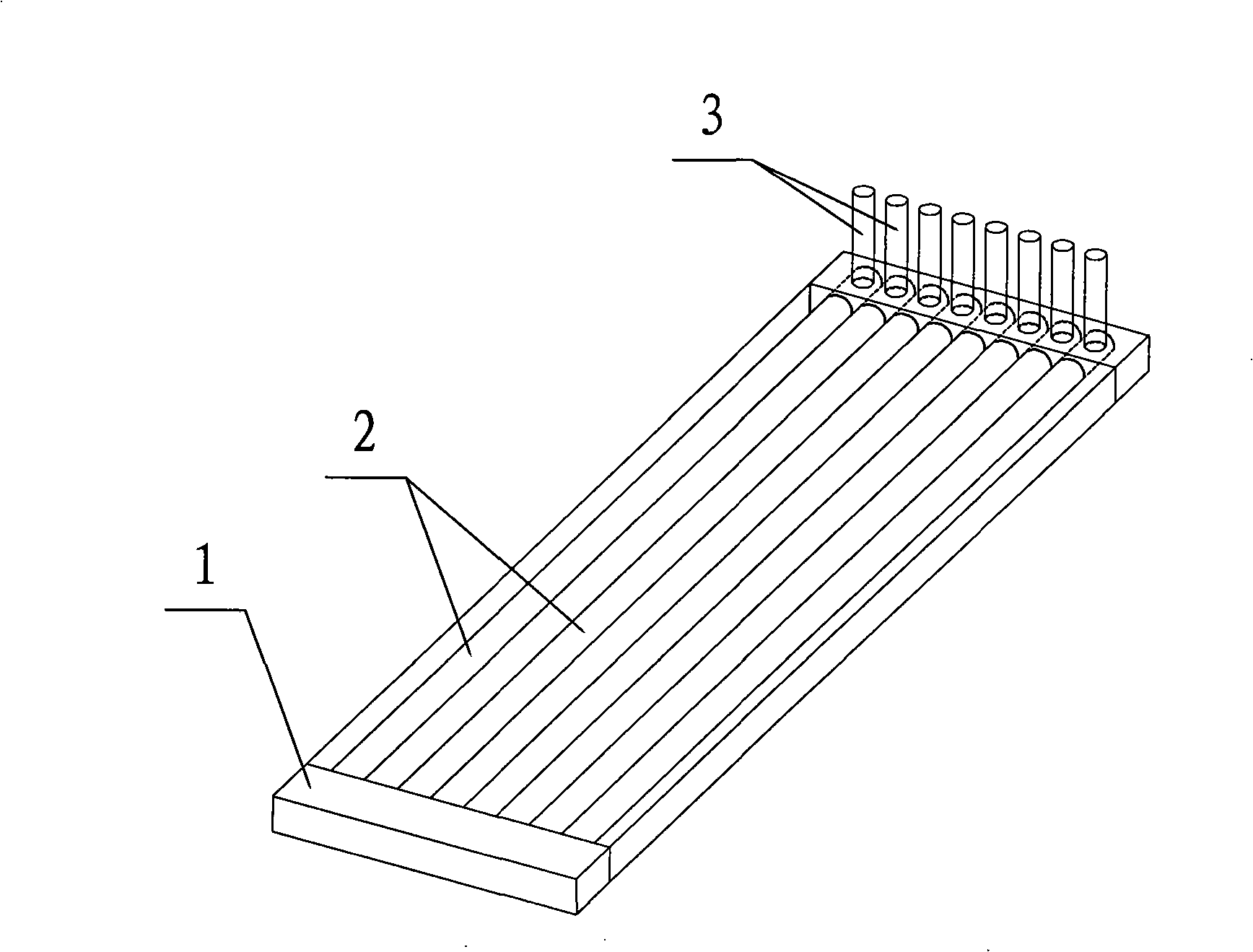

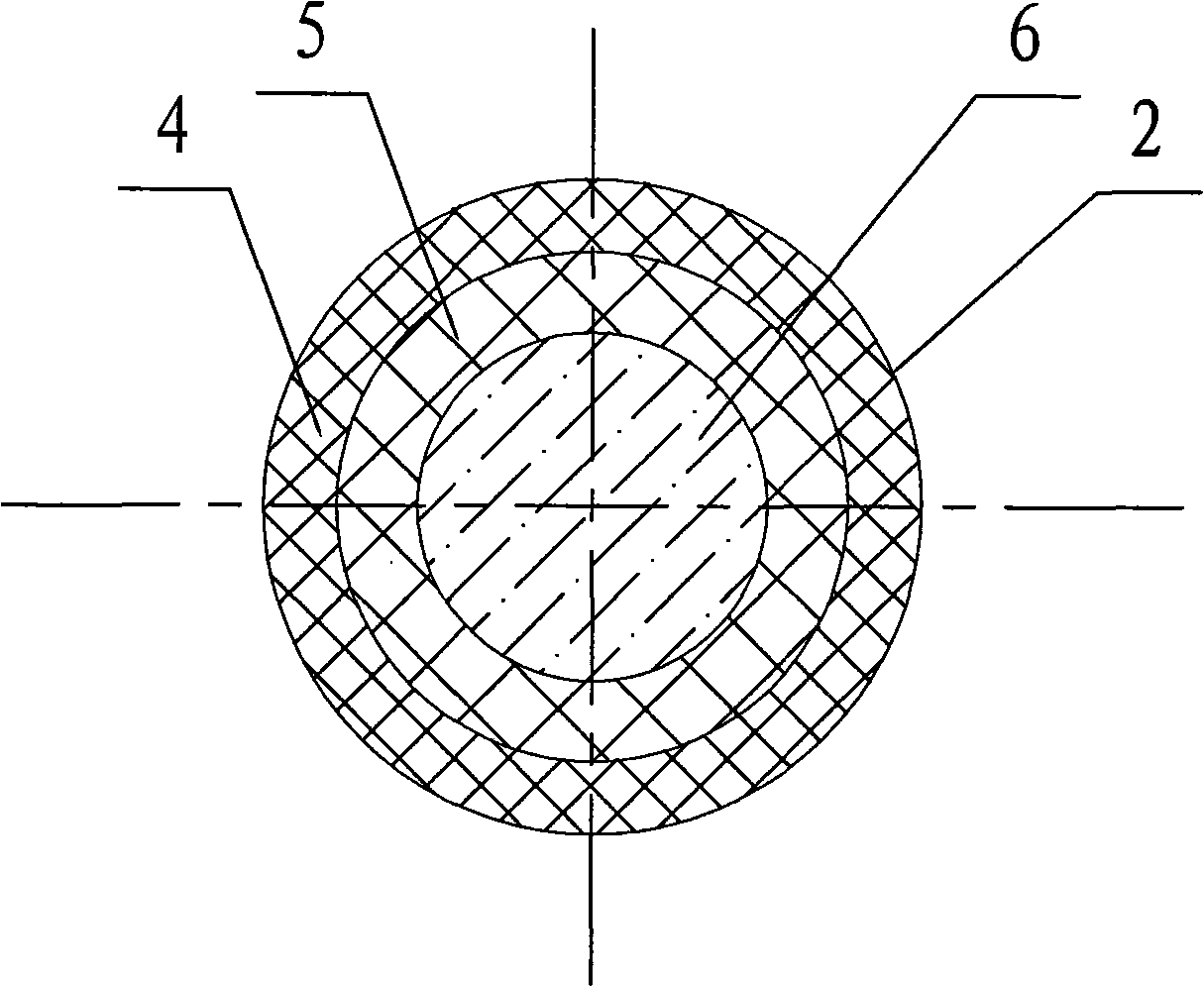

[0009] Specific implementation mode one: combine Figure 1 ~ Figure 2 Describe this embodiment, a deformed wing skin whose stiffness can be changed in this embodiment is composed of a silicon rubber skin base 1, a plurality of variable stiffness reinforcing tubes 2 and a plurality of control valves 3, and the plurality of variable stiffness reinforcing tubes The tubes 2 are embedded in the silicone rubber skin matrix 1 in parallel, and each control valve 3 is arranged on the outer surface of the silicone rubber skin matrix 1 and communicates with the corresponding variable stiffness reinforcing tube 2, and each variable stiffness reinforcing tube 2 has two The ends are all closed, and each of the variable stiffness reinforced pipes 2 is composed of a composite material outer layer 4, an inner liner pipe 5 and a working fluid 6, and the composite material outer layer 4 is wrapped on the outer surface of the inner liner pipe 5, The working fluid 6 is filled in the lining pipe 5 ...

specific Embodiment approach 2

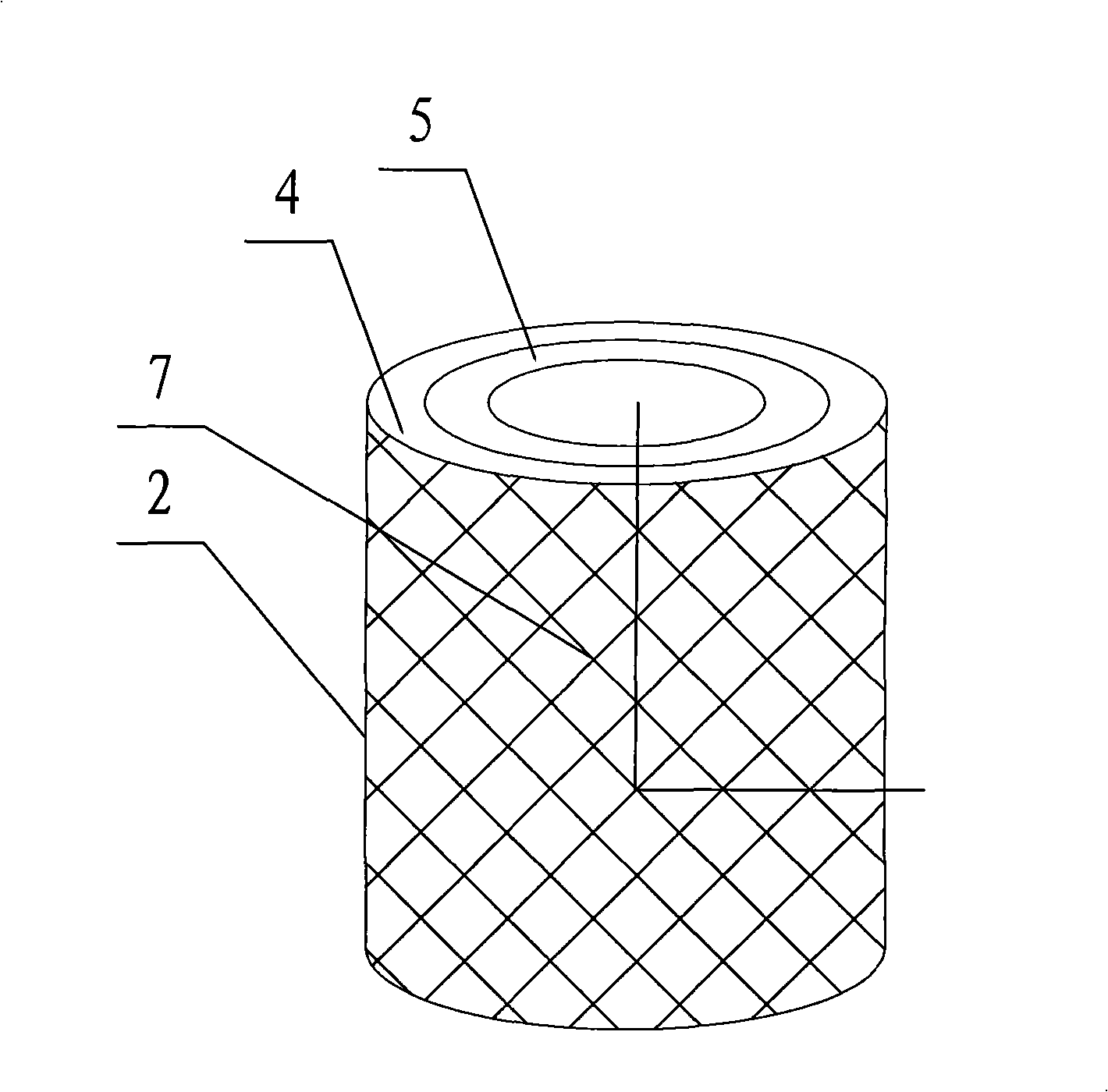

[0010] Specific implementation mode two: combination Figure 2 ~ Figure 3 To illustrate this embodiment, the outer layer 4 of the composite material in this embodiment is composed of a shape memory polymer matrix phase material and a reinforcement phase material; the reinforcement phase material accounts for 40% to 60% of the total volume of the outer layer 4 of the composite material; the reinforcement phase The fiber 7 of the material is compounded in the shape-memory polymer matrix phase material at an angle of 0°-90° to the radial direction of the variable-stiffness reinforced tube 2 . The shape memory polymer matrix material (SMP material) has a special memory function. When the SMP material is changed into a different shape layout, the SMP material molecules will reorganize to restore its original shape. The initial shape of the SMP material, That is to say that its "memory" shape is a rigid body, that is, a high modulus form. The SMP material used in the present inventi...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination image 3 To describe this embodiment, the fiber 7 of the reinforcing phase material of this embodiment is compounded in the shape memory polymer matrix phase material at an angle of 20°-40° to the radial direction of the variable stiffness reinforcing tube 2 . With such arrangement, the rigidity of the variable-stiffness reinforcing tube 2 is better. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com