Industrial intelligent digital continuous monitoring analysis method and system

An analysis method and analysis system technology, applied in the field of automation control, to achieve the effect of good compatibility, high performance, easy expansion and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

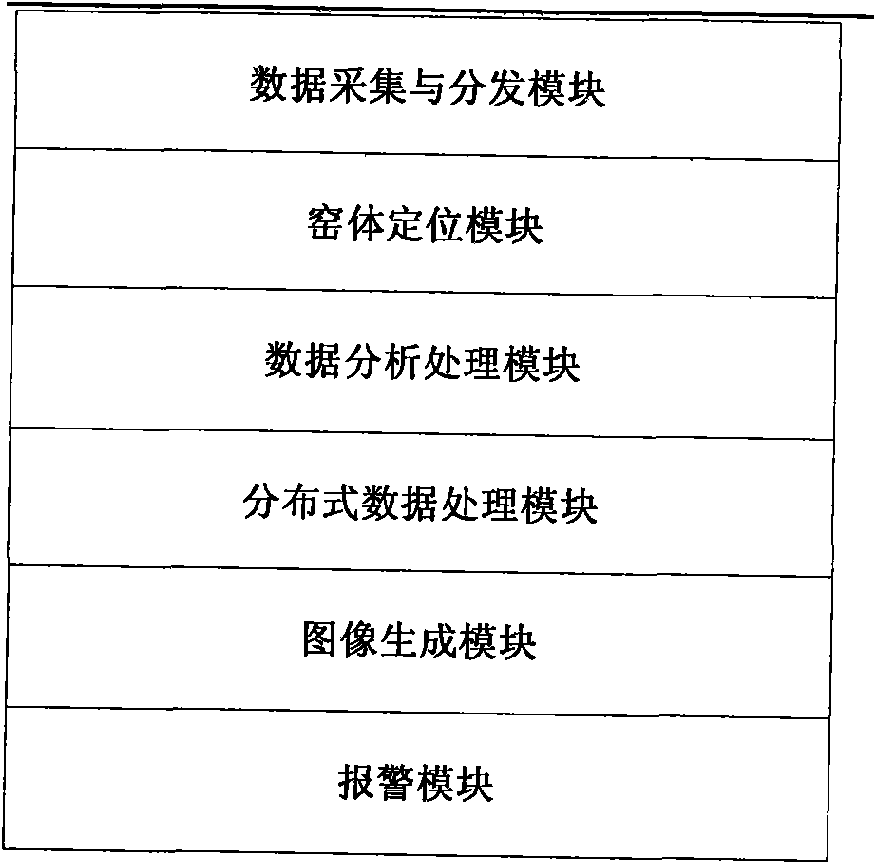

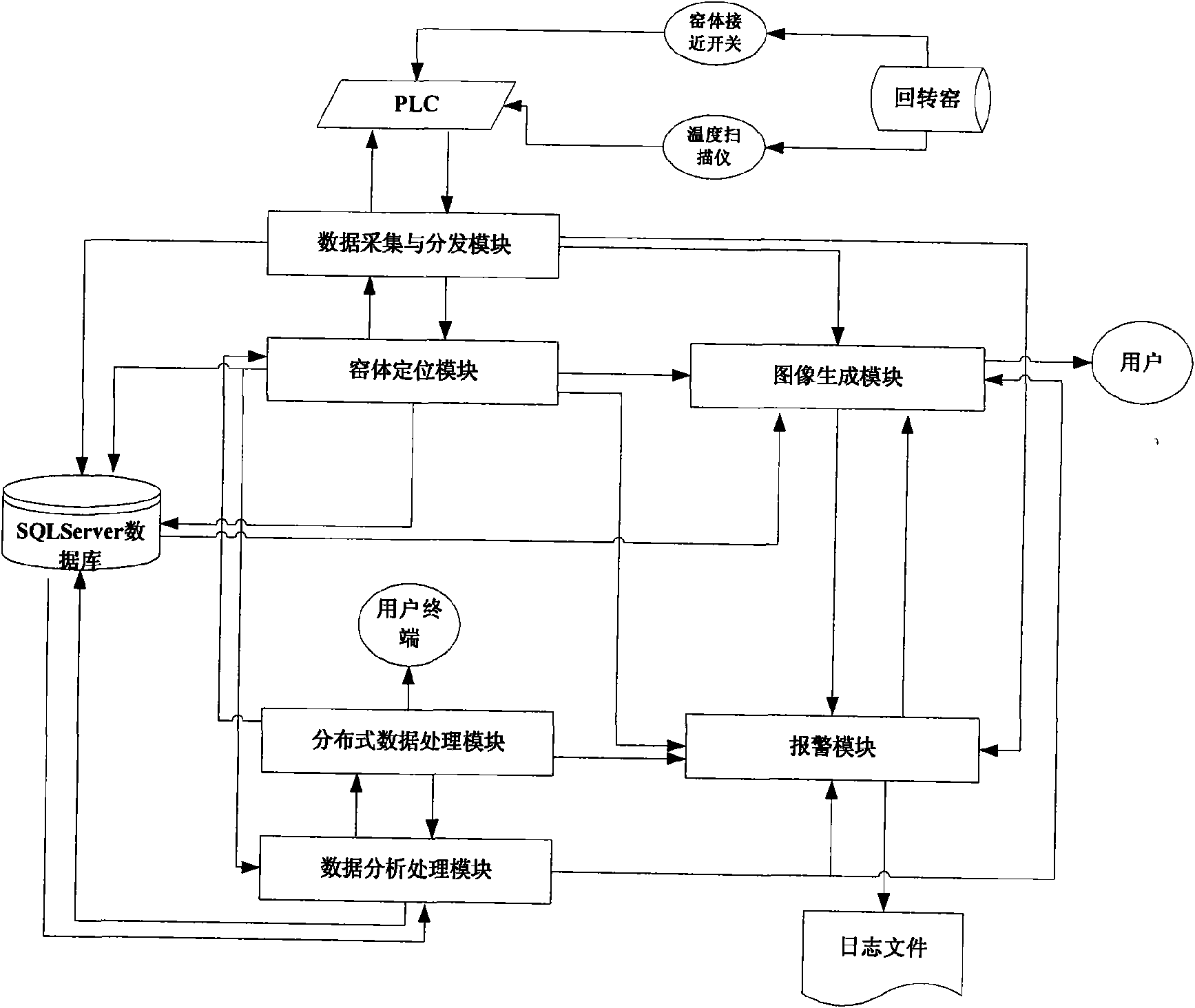

[0039]The system operation is divided into two parts: the server program and the client program; except the SOKET service program of the distributed data processing module and the terminal program are different, the functions of other modules are the same, and the server program can be used alone without adding the client , all functions of the server are all enabled by default; the client program can be configured according to user needs, including whether to add a database, whether to connect to a PLC, whether to display an alarm, etc. Both the server and the client program feed back information to the user, system alarm and receive user data settings through the user interface. First of all, the server runs on the monitoring server, and all functions are turned on. The server always monitors the entire surface of the kiln body, and provides complete database records and historical data recording functions; the client can be distributed in multiple computers in different loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com