Universal servocontrol platform device for motor-operating mechanism of high-voltage switch apparatus and method

A technology of operating mechanism and servo control, applied in the direction of AC motor control, electronic reversing motor control, power device inside the switch, etc., can solve the problems of complex operation, large overvoltage, non-replacement, etc., and achieve good control effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

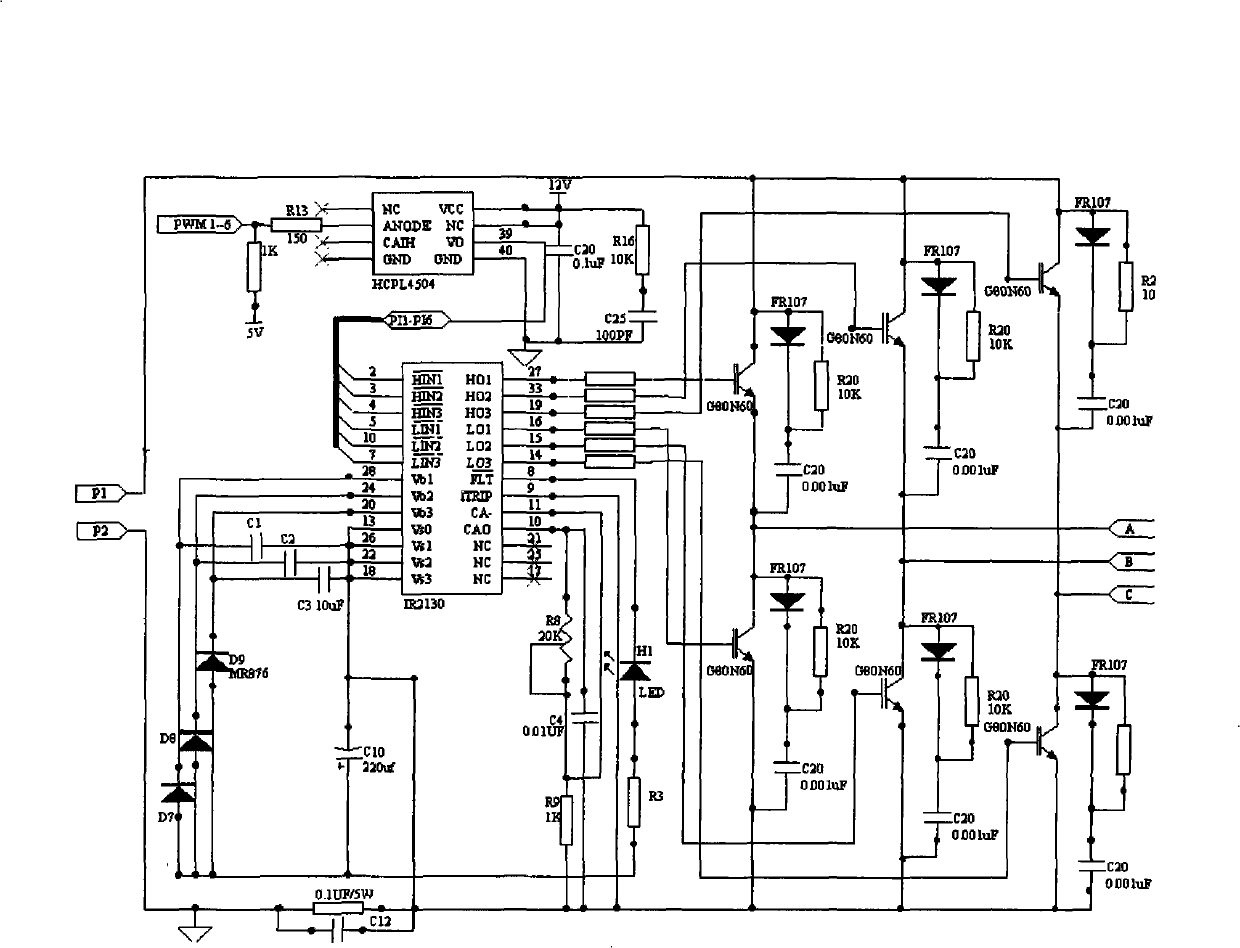

[0099] Embodiment 1: wherein the operating mechanism is a permanent magnet DC rotating motor, the model selected for the DSP chip is TMS320LF2407A, the model selected for the energy storage filter capacitor is 3300μF / 450V, the model selected for the isolation drive circuit is IR2130, and the selected model for the level conversion chip is The model is MAX3232, the model of the transfer bridge device 12 is RS232, the voltage dividing resistor is selected as 200Ω, the speed of the grating sensor 8 is 4.8m / s, and the resolution is 1μm.

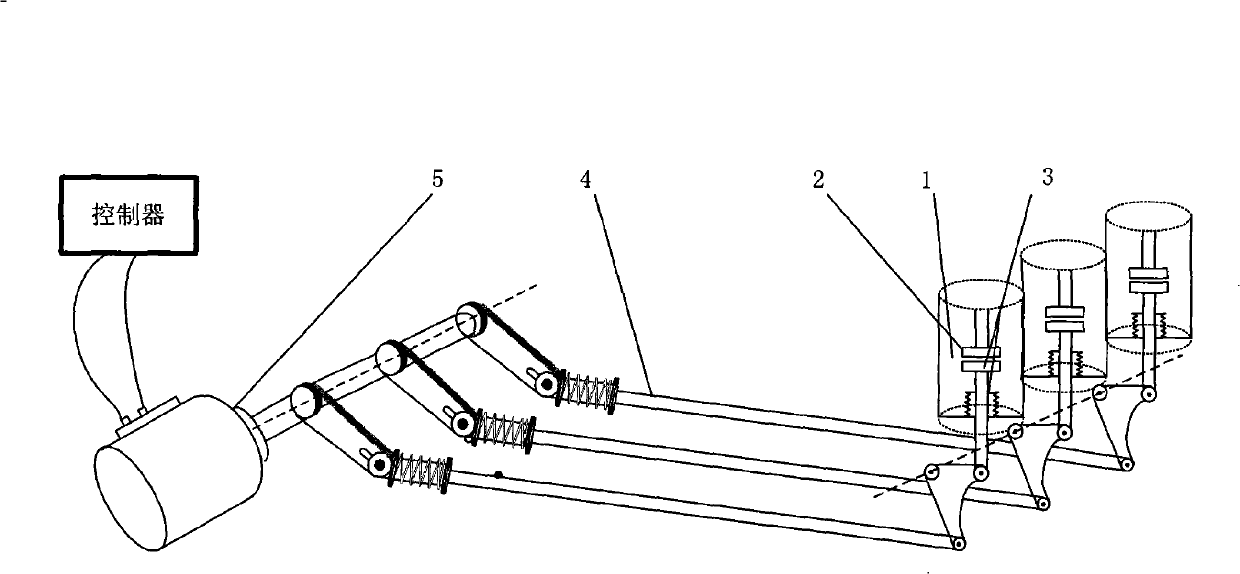

[0100] The device as figure 1 As shown, it includes an operating mechanism, a main circuit 10 and a control circuit 6. The operating mechanism includes a permanent magnet DC rotating motor 5, a connecting rod 4, a high voltage circuit breaker, a temperature sensor 13, a voltage sensor and a grating sensor 8, and the permanent magnet DC rotating The motor 5 is connected to the high-voltage circuit breaker through the connecting rod 4, and the main...

Embodiment 2

[0180] Embodiment 2: The operating mechanism is a permanent magnet DC linear motor, the motor is a permanent magnet DC linear motor with a position sensor, the model selected for the DSP chip is TMS320LF2407A, the model selected for the energy storage filter capacitor is 3300μF / 450V, and the isolated drive The selected model of the circuit is IR2130, the selected model of the level conversion chip is MAX3232, the model of the transfer bridge device 12 is RS232, the voltage dividing resistor is selected as 200Ω, the speed of the grating sensor 8 is selected as 4.8m / s, and the resolution is 1μm.

[0181] The device as Figure 13 As shown, it includes an operating mechanism, a main circuit 10 and a control circuit 6. The operating mechanism includes a permanent magnet DC linear motor 14, a connecting rod 4 and a high-voltage circuit breaker, a temperature sensor 13, a voltage sensor and a grating sensor 8. The motor passes through the connecting rod 4 Connect the high-voltage cir...

Embodiment 3

[0260] Embodiment 3: wherein the operating mechanism is a cylindrical linear induction motor, the motor is a permanent magnet DC linear motor with a position sensor, the model selected for the DSP chip is TMS320LF2407A, and the model selected for the energy storage filter capacitor is 3300μF / 450V, isolated The selected model of the driving circuit is IR2130, the selected model of the level conversion chip is MAX3232, the model of the transfer bridge device 12 is RS232, the voltage dividing resistor is selected as 200Ω, the speed of the grating sensor 8 is selected as 4.8m / s, and the resolution is 1μm.

[0261] The device as Figure 16 As shown, it includes an operating mechanism, a main circuit 10 and a control circuit 6. The operating mechanism includes a cylindrical linear induction motor 15, a connecting rod 4, a high-voltage circuit breaker, a temperature sensor 13, a voltage sensor and a grating sensor 8, and the motor passes through the connection. Rod 4 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com