Method for preparing marsh gas by fermenting steam-exploded wood fiber straws

A technology of lignocellulosic and steam-exploded straw, which is applied in fermentation, waste fuel, etc., and can solve the problems of lignocellulosic straw inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

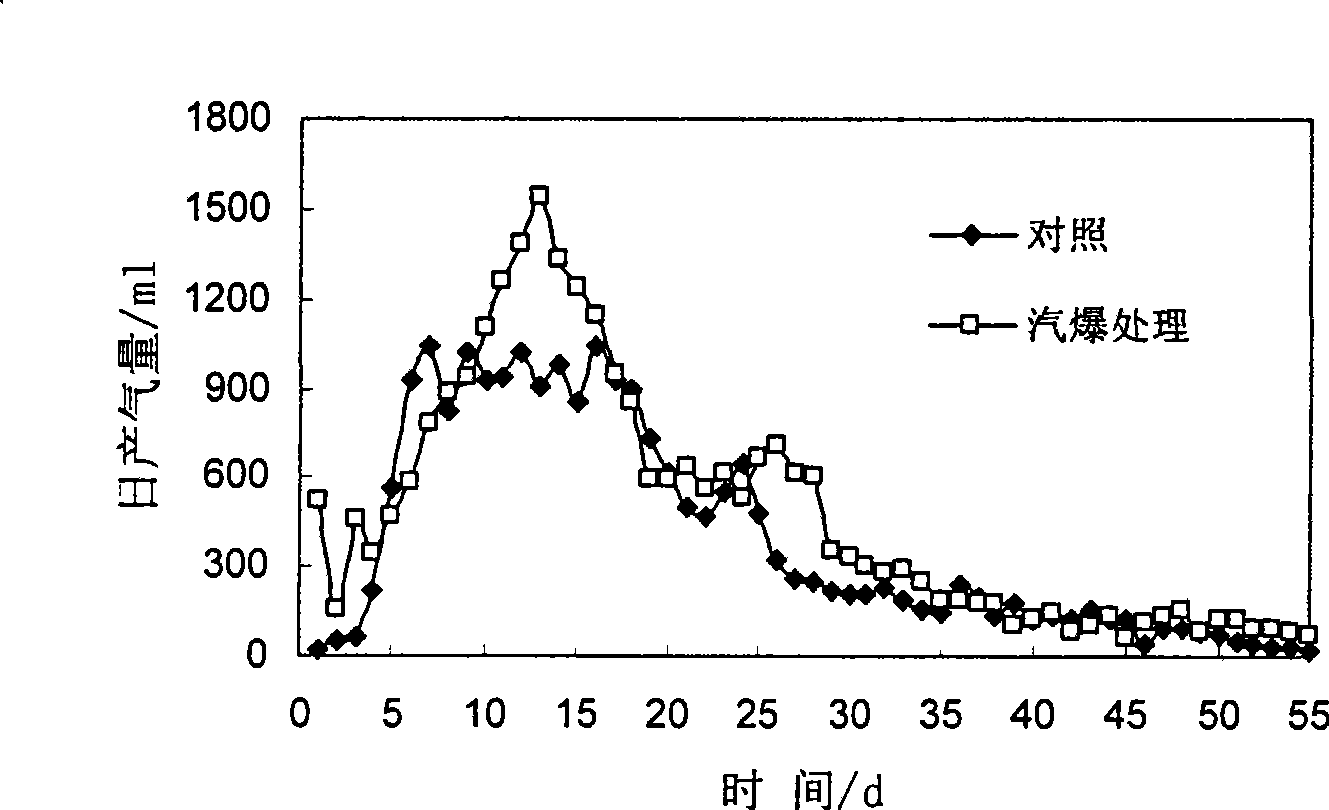

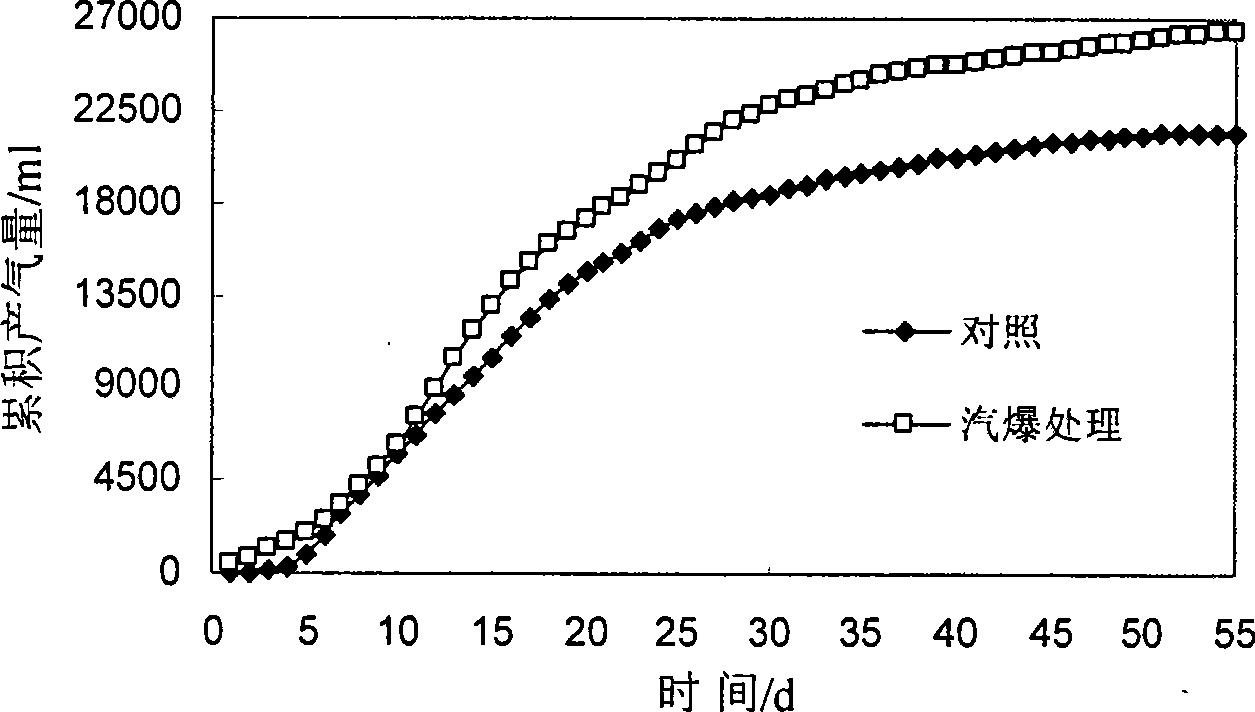

Embodiment 1

[0017] Spartina alterniflora was treated with steam explosion as the fermentation raw material. The steam explosion equipment was produced by Henan Hebi Zhengdao Technology Co., Ltd. The opening time of the explosion valve of this equipment was 0.00875s, the steam explosion condition was 1.5MPa, and the pressure maintenance time was 90s. The experiment was carried out by batch fermentation, using 2500mL faucet tank as the anaerobic reactor, the total weight of the material was 1500g, the TS concentration was 6%, the inoculum concentration was 45%, the fermentation period was 55d, and the experiments were performed in parallel. At the beginning of the test, fill the reactor with nitrogen for 2 minutes to drive away the air in the reactor, seal it with a rubber stopper, put it into the incubator, set the temperature in the incubator to 35°C, and collect the biogas by drainage method. Shake the reactor manually every day to stir the materials in the reactor; check the airtightness...

Embodiment 2

[0020] Corn stalks treated with steam explosion were used as fermentation raw materials. The steam explosion equipment was produced by Henan Hebi Zhengdao Technology Co., Ltd. The opening time of the explosion valve of this equipment was 0.00875s, the steam explosion condition was 2.0MPa, and the pressure maintenance time was 90s. The test was carried out by batch fermentation, using a 1000mL jar as an anaerobic reactor, with a total material weight of 500g, a TS concentration of 6%, an inoculum concentration of 45%, and a fermentation period of 60 days. Two experiments were performed in parallel. At the beginning of the test, fill the reactor with nitrogen for 2 minutes to drive away the air in the reactor, seal it with a rubber stopper, put it into the incubator, set the temperature in the incubator to 35°C, and collect the biogas by drainage method. Shake the reactor manually every day to stir the materials in the reactor; check the airtightness of the reaction device regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com