Inverted cup-type drop test bed cradle

A test-bed and cup-type technology is applied in the field of landing gear dynamic test devices, which can solve the problems of adjustable stiffness, high structure height, and heavy weight of the hanging basket structure without considering the problems of space-saving height, adjustable stiffness in all directions, The effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

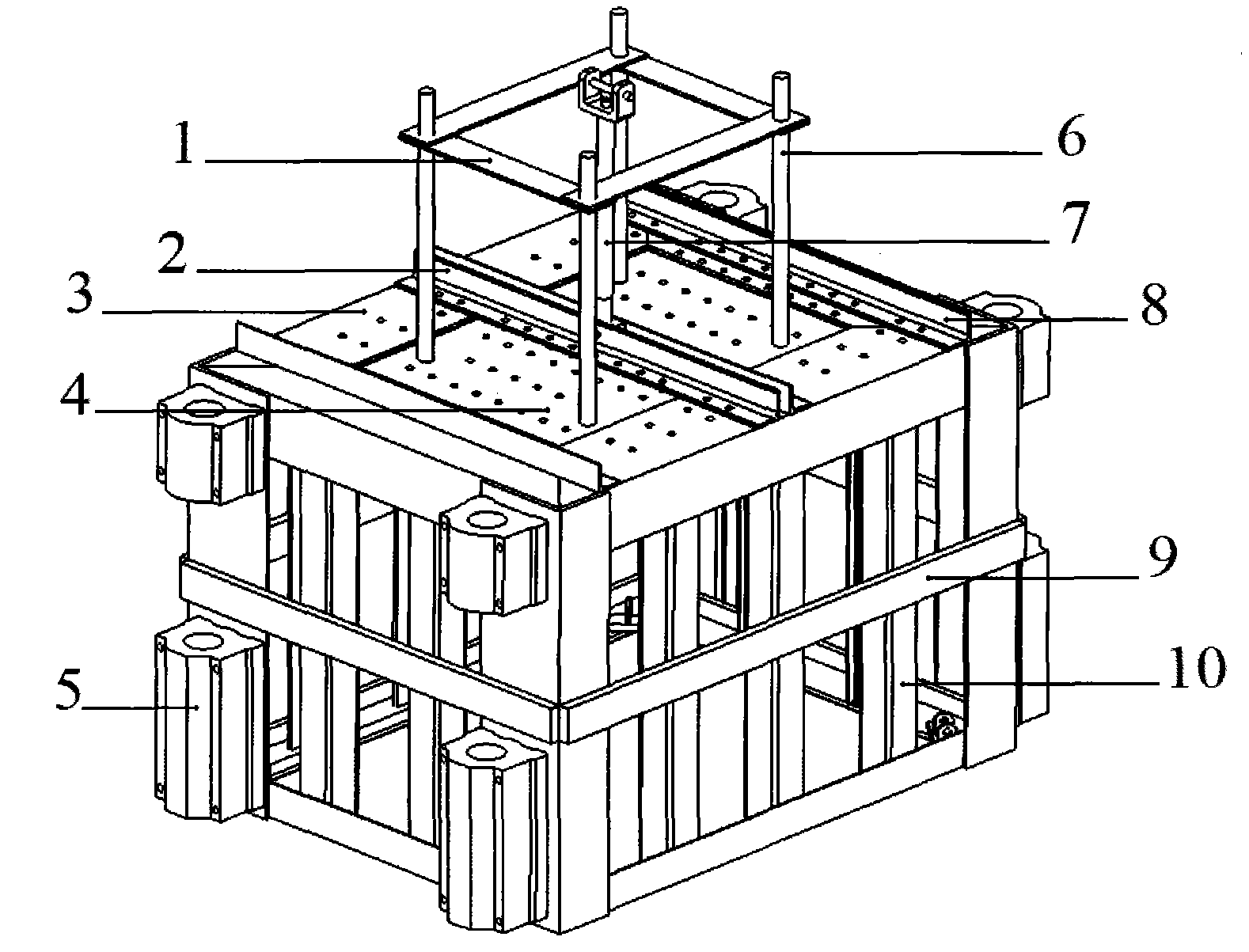

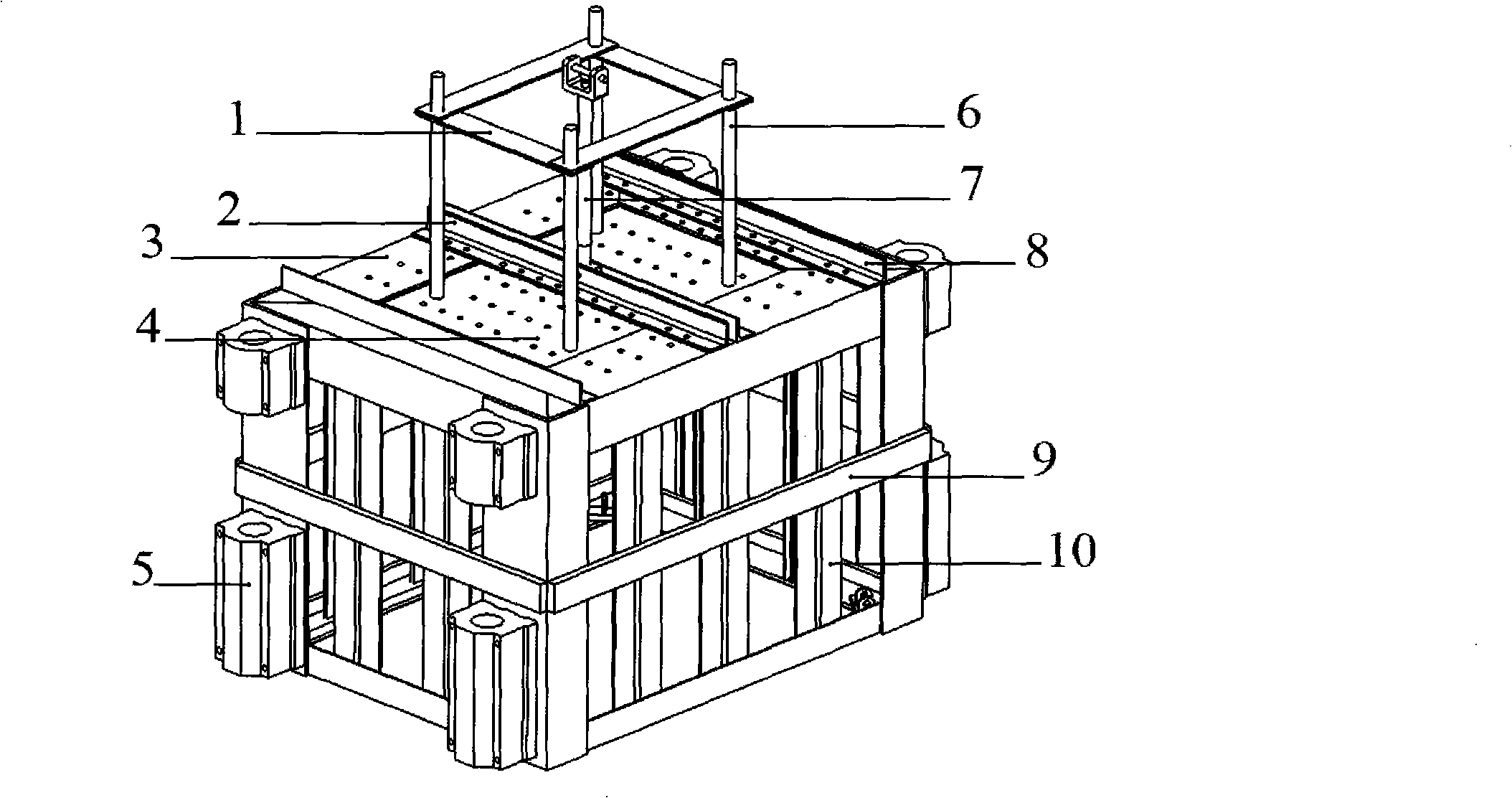

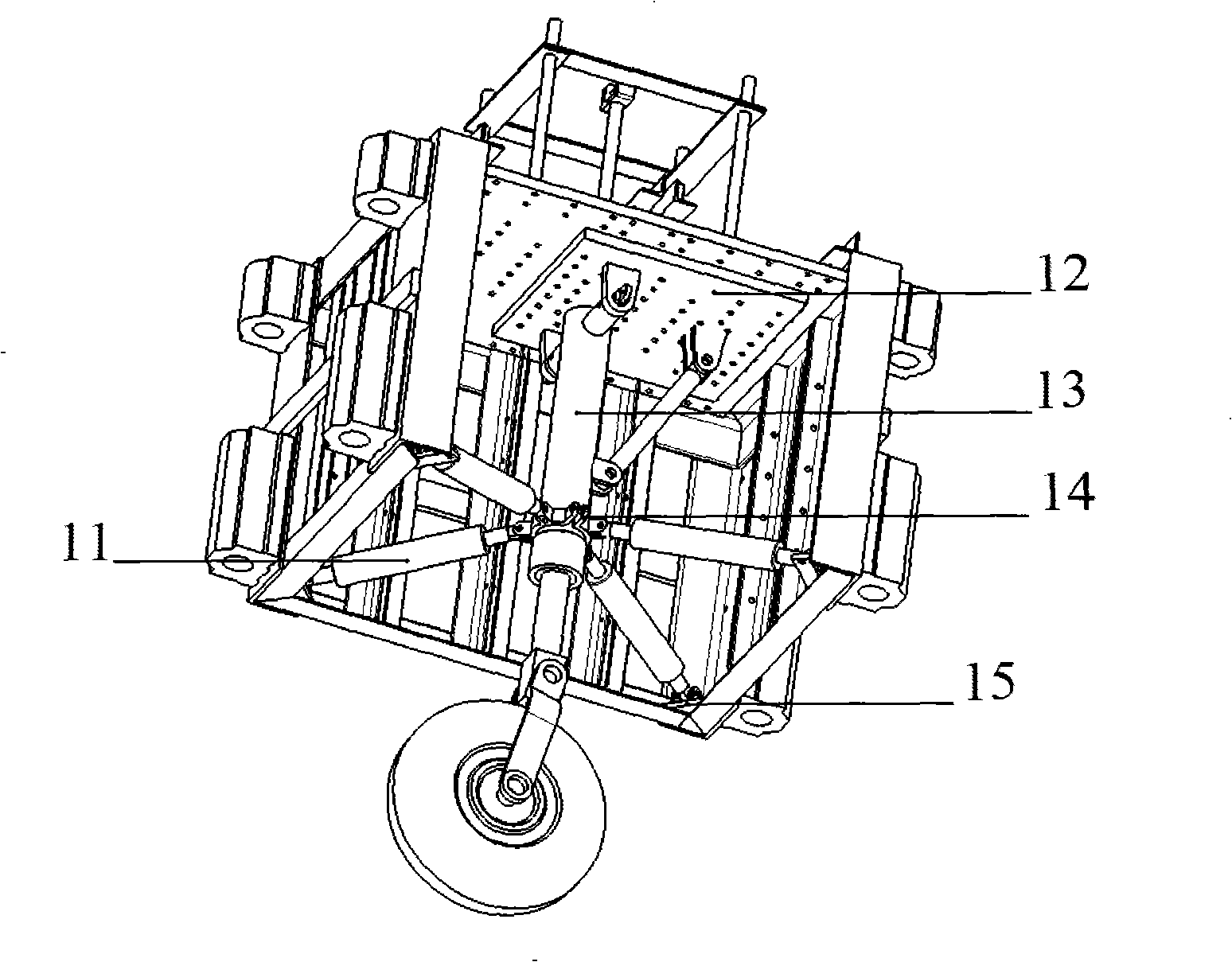

[0030] As shown in Figure 1, this embodiment is mainly composed of a coaming plate 1, a fixing piece 2, an unequal angle steel 3, a hanging basket top plate 4, a box-type linear bearing 5, a weight screw 6, a boom 7, a fixed angle steel 8, and reinforcement Rib plate 9, reinforced angle steel 10, lug support 15 etc. are formed. Among them, the unequal angle steel 3, the rib plate 9 and the reinforced angle steel 10 are welded to form a semi-closed box structure. Among the six sides of the box structure, the surrounding four sides are closed, and the top and bottom two sides are open. The wide sides of the unequal angle steel on the top of the box body and the top plate 4 of the hanging basket and the fixed angle steel 8 are connected by bolts, so that the top is closed. Among the four fixed angle steels on the top plate of the hanging basket, the middle two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com