Light trapping structure for thin film solar cell

A technology of thin-film solar cells and light-trapping structures, applied in the field of light-trapping structures, can solve the problems of inconspicuousness, complicated preparation process, and high cost of solar cells, and achieve the effects of easy processing and production, large light-trapping efficiency, and high light-trapping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

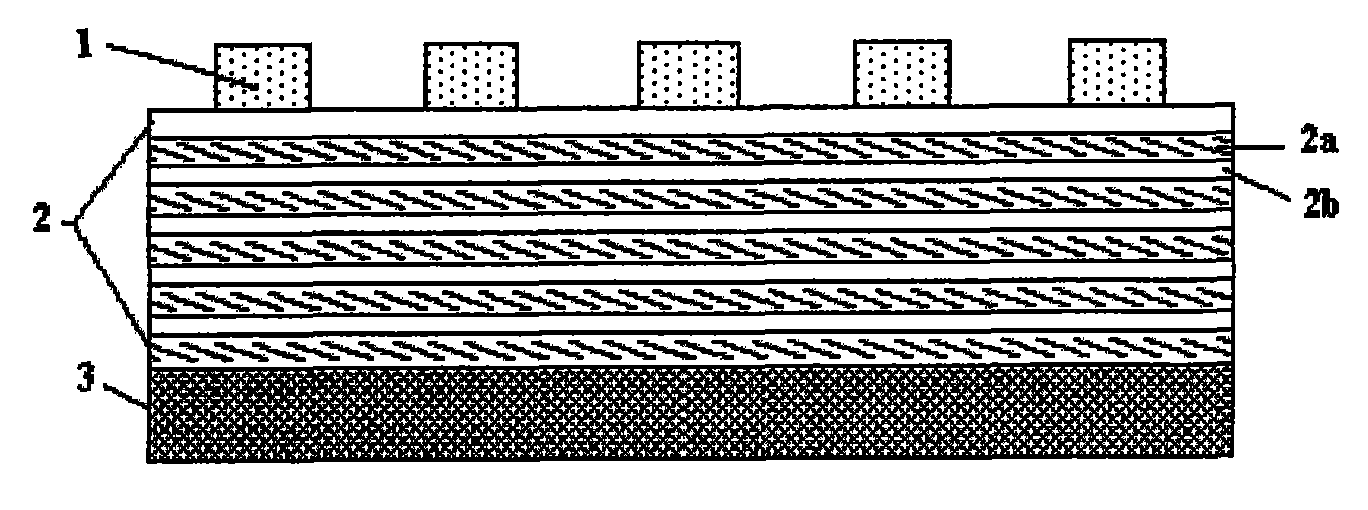

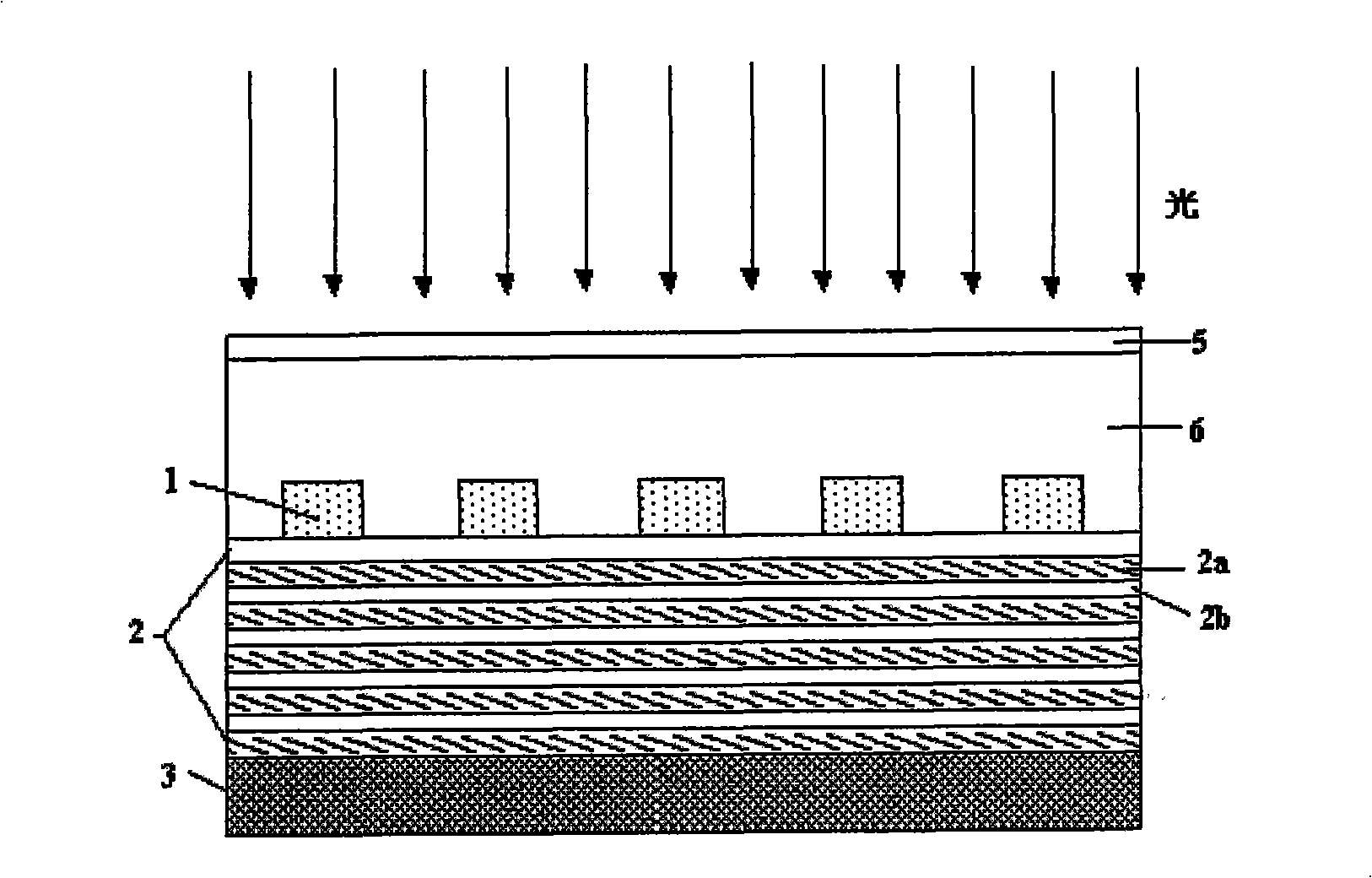

[0027] Such as image 3 As shown in , a light-trapping structure of the present invention is applied to the backlight surface of a thin-film silicon solar cell. In the figure, 1 is a diffraction grating, 2 is a distributed Bragg reflector (DBR), 2a and 2b are two material layers with different refractive indices that constitute the DBR, 3 is a metal reflector, 5 is an ITO anti-reflection coating, 6 It is a thin film silicon layer; wherein, the diffraction grating 1, the distributed Bragg reflector (DBR) 2 and the metal reflector 3 jointly constitute a light trapping structure of the present invention. In this embodiment, the constituent material of the diffraction grating 1 is indium tin oxide (ITO), the constituent material of the distributed Bragg reflector (DBR) 2 is 2a: doped a-Si, 2b: ITO, and the composition of the metal reflector 3 The material is Ag. The light-trapping structure of the present invention thus obtained is conductive.

[0028] When the thickness of the...

Embodiment 2

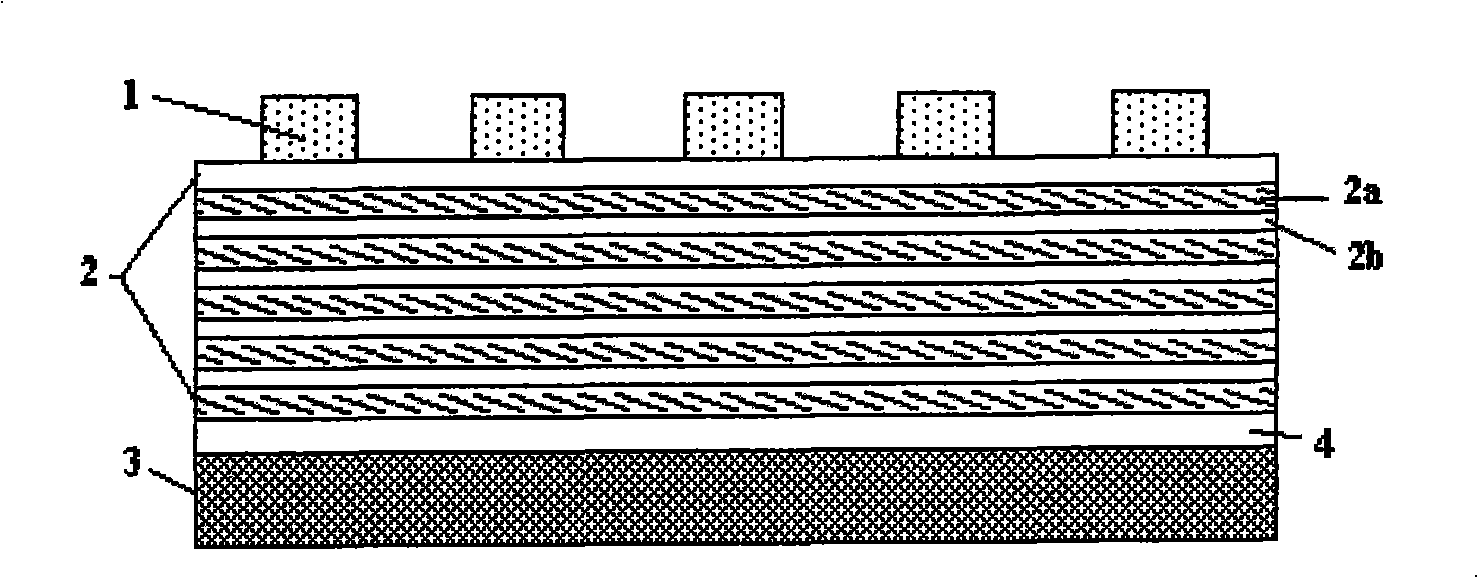

[0030] Such as Figure 5 As shown in , a light-trapping structure of the present invention is applied to the backlight surface of a thin-film silicon solar cell. In the figure, 1 is a diffraction grating, 2 is a distributed Bragg reflector (DBR), 2a and 2b are two material layers with different refractive indices that constitute the DBR, 3 is a metal reflector, 4 is a dielectric buffer layer, and 5 is ITO The anti-reflection coating, 6, is a thin film silicon layer; wherein, the diffraction grating 1, the distributed Bragg reflector (DBR) 2, the metal reflector 3 and the dielectric buffer layer 4 together constitute a light trapping structure of the present invention. In this embodiment, the constituent material of the diffraction grating 1 is indium tin oxide (ITO), the constituent material of the distributed Bragg reflector (DBR) 2 is 2a: doped a-Si, 2b: ITO, and the composition of the metal reflector 3 The material is Ag, and the constituent material of the dielectric buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com