Large-scale ring rolling machine proportion servo-control system

A servo control system and control system technology, applied in the direction of rolling mill control devices, use feedback control, metal rolling, etc., can solve the problems of unrealistic no-load simulated test run, difficult CNC automatic production, poor system controllability, etc., to achieve The load test is convenient and reliable, the conversion is flexible and convenient, and the effect of simplifying the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

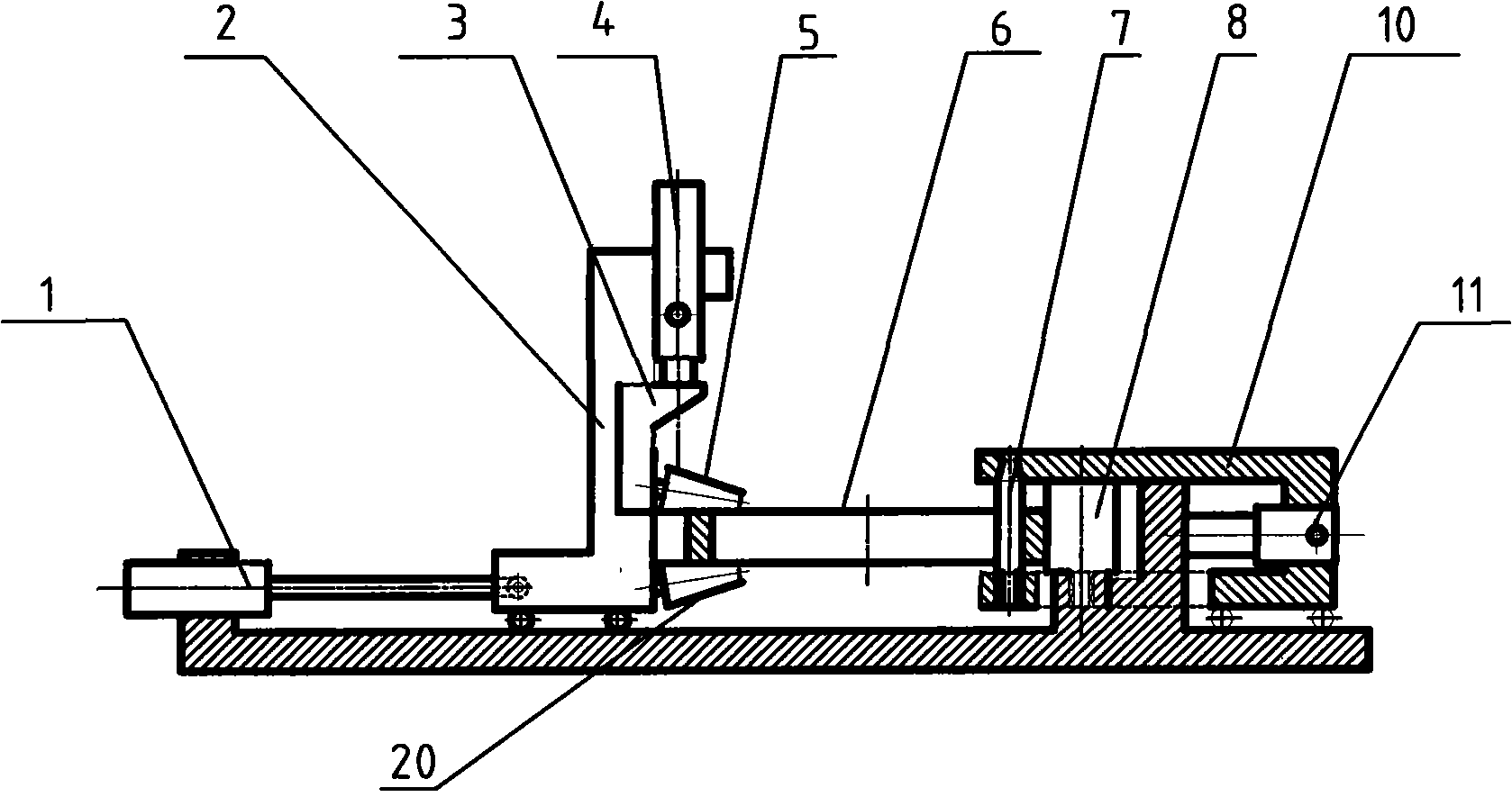

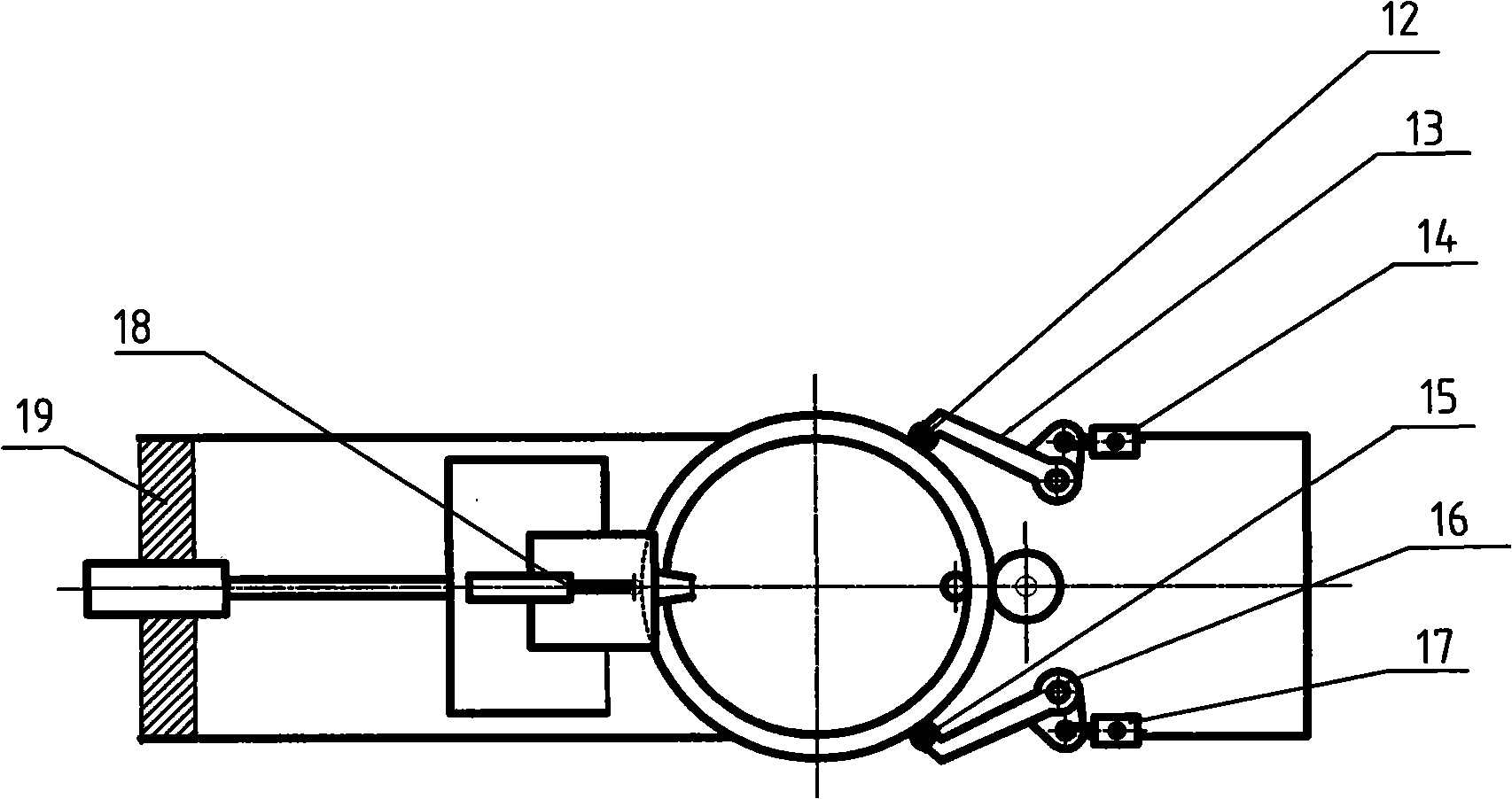

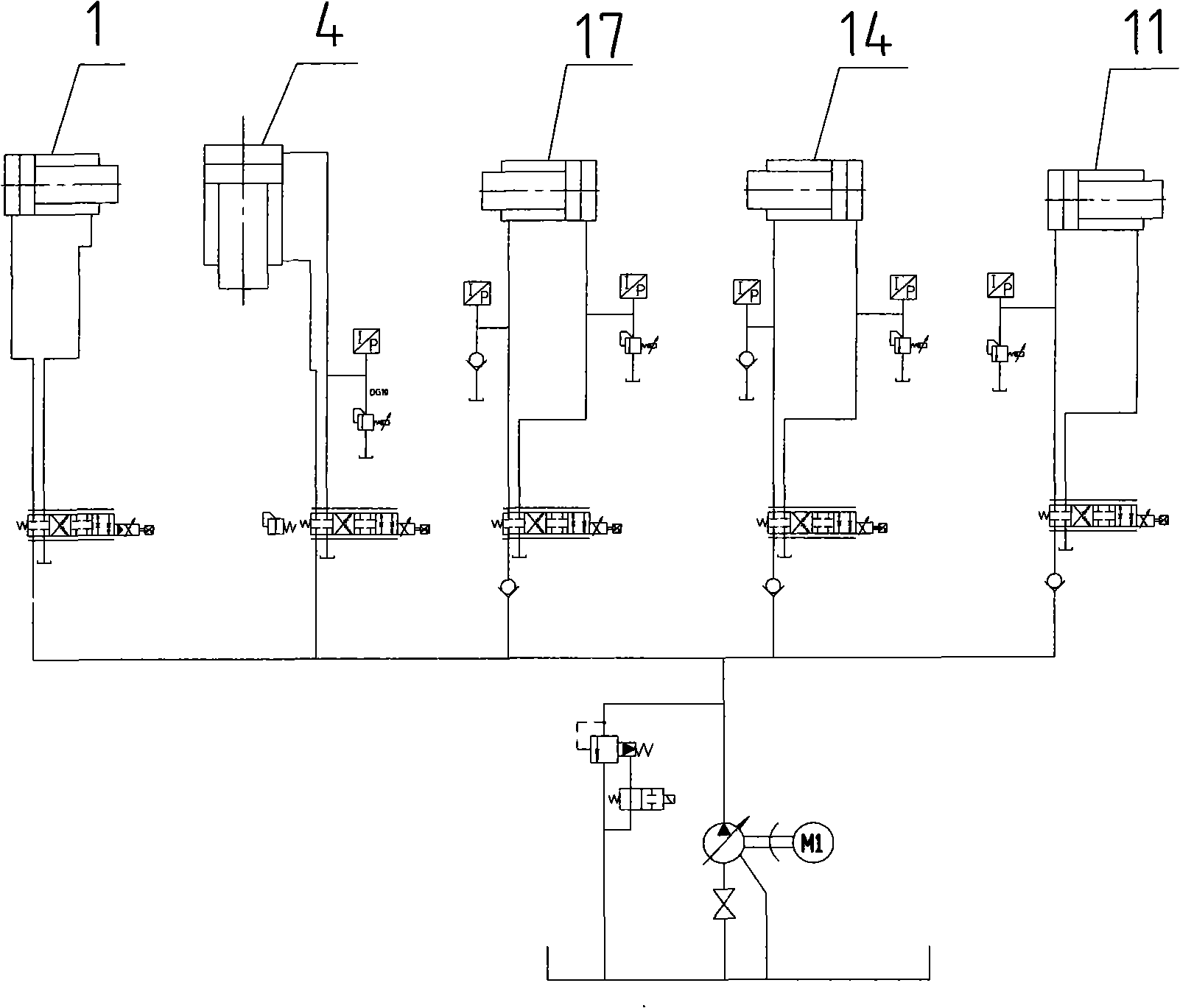

[0026] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a five-axis control system formed by a radial rolling control system, an axial rolling control system, a follower stand control system, a centering roll rolling control system, and a tapered roll speed control system. Rolling control system: including the radial rolling slider 10 that performs horizontal reciprocating motion in the guide rail of the bed. One end of the radial rolling slider 10 is connected with a radial rolling cylinder 11 that controls its movement. The other end of the slide block 10 is connected with the core roller 7 positioned at the inner side of the rolled ring 6; the follow-up frame control system: includes the mobile frame 2 and the mobile frame cylinder 1 for controlling its movement, and the mobile frame cylinder 1 Fixed on the frame 19, the measuring cylinder 18 on the mobile frame 2 controls the measuring roller to be close to the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com