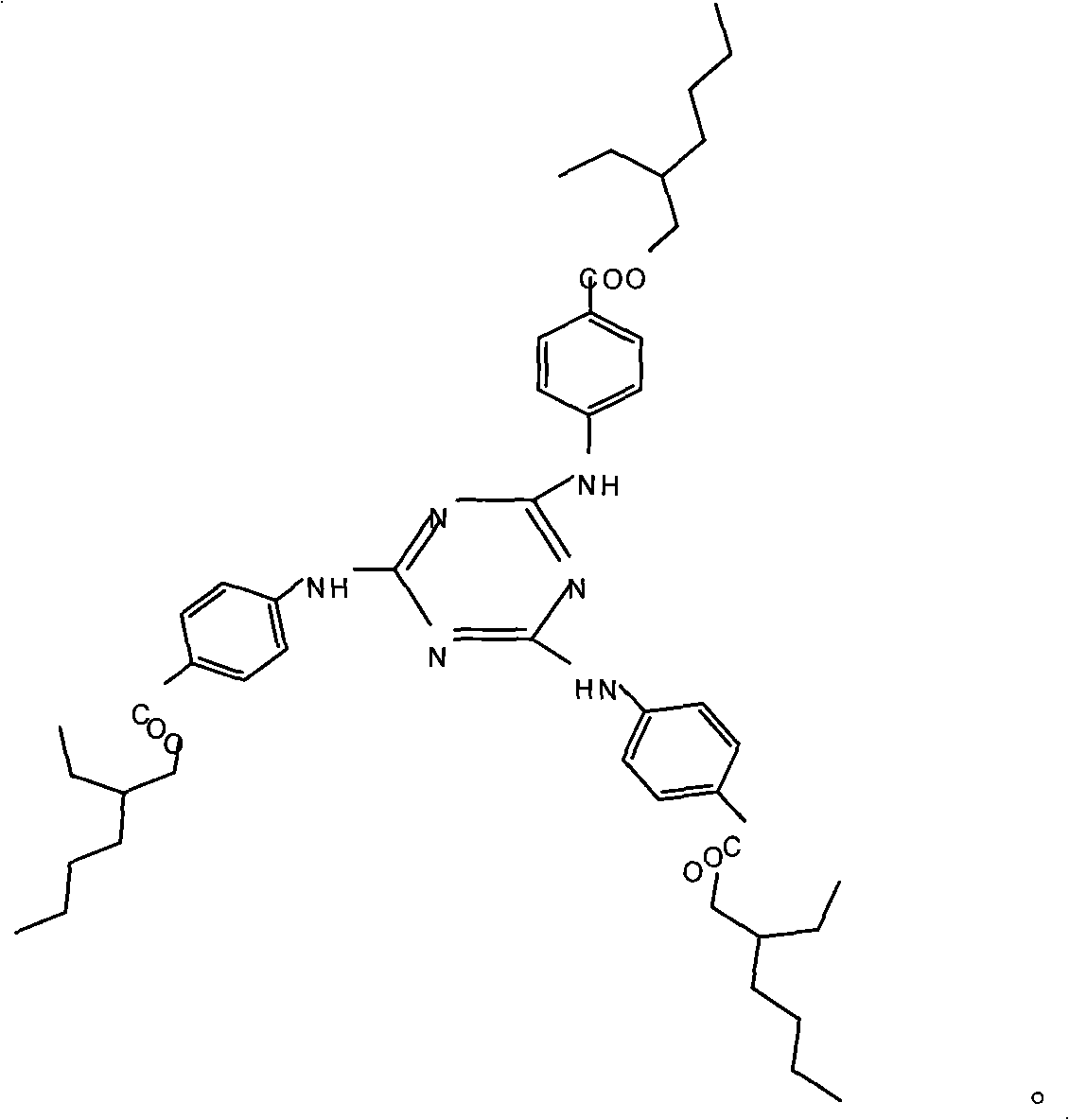

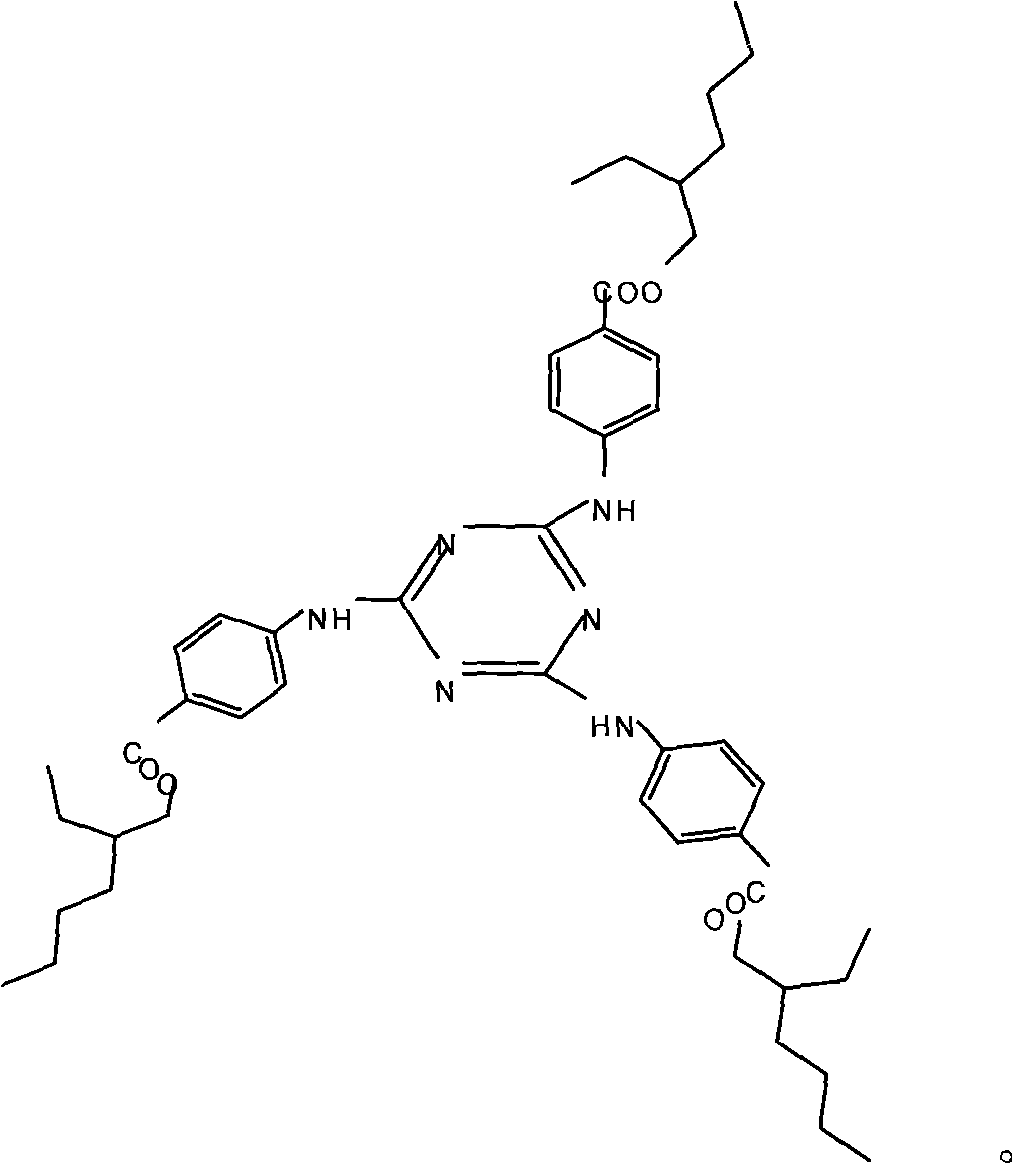

Preparation technology of octyl triazone and tautomer thereof

A technology of tautomers and octyl triazone, which is applied in the field of preparation technology of octyl triazone and its tautomers, can solve the problems affecting the production of octyl triazone and its tautomers Product yield, product yield needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Cyanuric chloride and isooctyl p-aminobenzoate are refluxed in xylene or ethylbenzene for 16 hours to remove the solvent, add three times the weight of ethanol to isooctyl p-aminobenzoate, and reflux to make it completely dissolved. , add water equivalent to 15% of the weight of ethanol, cool to room temperature under vigorous stirring, and two phases begin to appear. After stirring for several hours, the material gradually solidifies and precipitates, and then centrifuged, washed with petroleum ether, and dried to obtain the target product.

Embodiment 2

[0012] After cyanuric chloride and isooctyl p-aminobenzoate were refluxed in dimethylbenzene or ethylbenzene for 16h to remove the solvent, add three times the weight of methanol and ethanol mixed solution of isooctyl p-aminobenzoate Accounting for the mixed solution weight ratio is 20%), reflux, after making it completely dissolved, add water equivalent to 15% of the mixed solution gross weight, cool to room temperature under vigorous stirring and two phases appear, and the material slowly hardens after stirring for several hours. After solidification and precipitation, the target product was obtained by centrifugation, washing with petroleum ether, and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com