Adsorption-heatpump coupling drying system

A technology of drying system and heat pump system, applied in the directions of heat pump, drying gas arrangement, local stirring dryer, etc., can solve the problem of large cooling capacity consumption, achieve the effect of wide application range, increase speed and improve material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

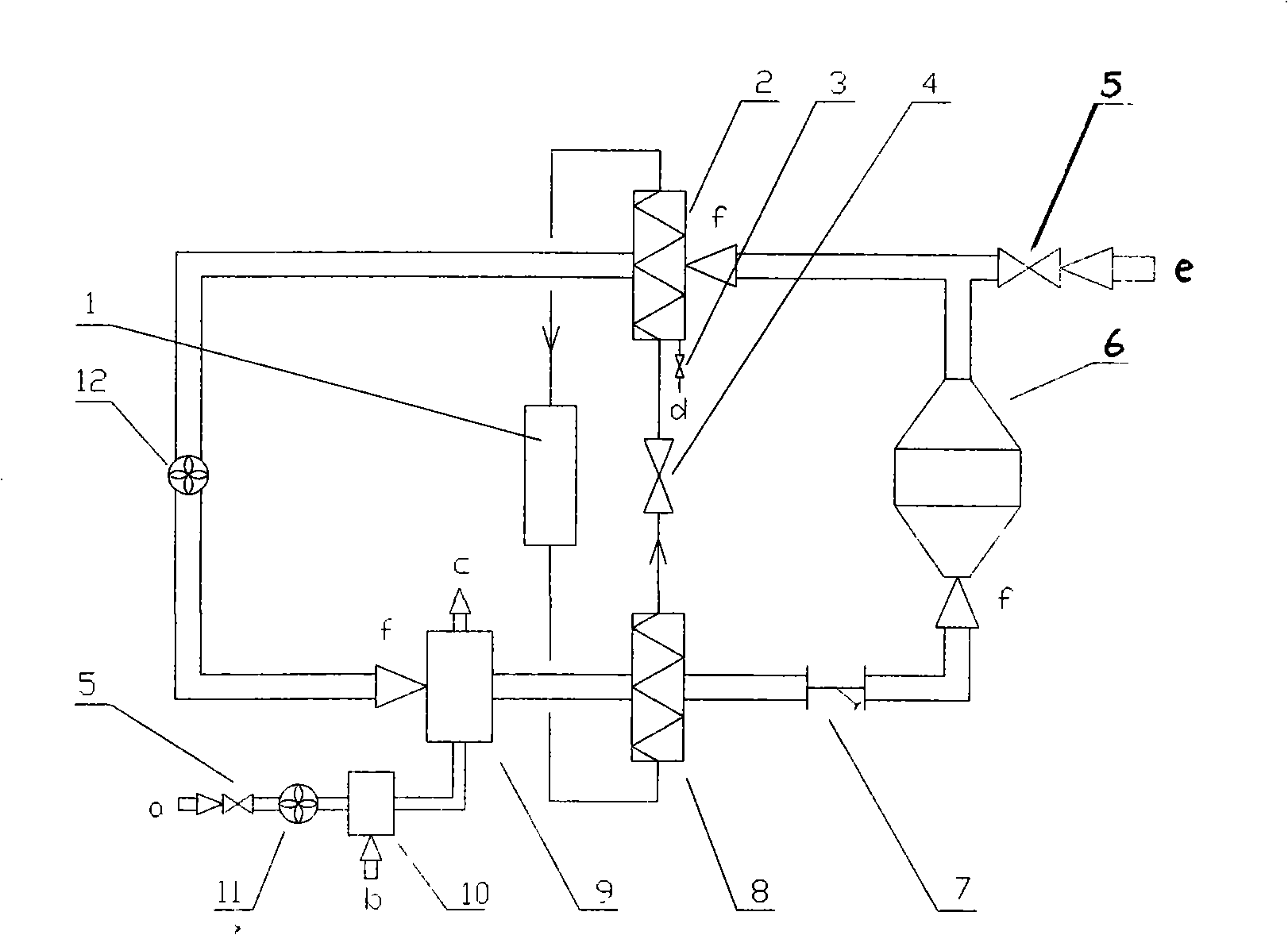

[0028] The present invention can be combined with figure 1 practice, but does not limit the scope of use of the present invention.

[0029] Combined with the specific components in the accompanying drawings, the application process of the adsorption-heat pump coupled drying system is as follows.

[0030] After the drying medium gas f of the drying system dries the materials in the drying box 6, the temperature of the gas decreases and the humidity increases, and is sent to the evaporator 2 of the heat pump system by the drying fan 12 to cool and dehumidify, and the moisture in the gas is condensed to remove, and the condensed moisture d is discharged from the drying system through the drain valve 3, the temperature of the cooled gas is further reduced, and becomes a low-temperature, low-humidity gas, which is sent to the adsorption dehumidifier 9 for further adsorption and dehumidification, the humidity of the gas is further reduced, and the dew point is as low as 40°C. The ...

Embodiment 2

[0035] 10kg of fresh shiitake mushrooms (with a moisture content of about 90%) are dried through processes such as sorting, cleaning, sterilizing pretreatment, and draining. The drying process conditions are as follows: the drying medium is air, the temperature of the drying medium is 60° C., and the relative humidity is 2%. During the drying process, the high-humidity air temperature at the outlet of the drying box 6 is 45°C, and the relative humidity is 90%; the air flow is cooled by the evaporator 2 of the heat pump system to remove a large amount of moisture. 96%; the airflow is further adsorbed and dehumidified by the adsorption dehumidifier 9, the temperature rises to 30°C, and the relative humidity drops to 10%; the airflow is finally further adjusted to a temperature of 60°C and a relative humidity of 2% through the condenser 8 of the heat pump system , enter drying box 6 and carry out mushroom drying. Dry the shiitake mushrooms until the water content is 15%, stop dr...

Embodiment 3

[0037] 5kg of fresh tangerines (moisture content about 80%) are dried through operations such as finishing, cleaning, and draining. The drying process conditions are as follows: the drying medium is carbon dioxide, the temperature of the drying medium is 50° C., and the relative humidity is 5%. Dry to a moisture content of 3%, stop drying. The orange peel obtained after drying maintains bright color and strong smell, and saves energy by 50-55% compared with freeze-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com