BOPP extinction film without anti-adhesion agent and production method thereof

An anti-blocking agent and matting film technology, applied in chemical instruments and methods, flexible coverings, packaging, etc., can solve the problems of affecting matting effect, uneven distribution of matting materials, increasing cost, etc., to improve matting effect and matting. Good effect, the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

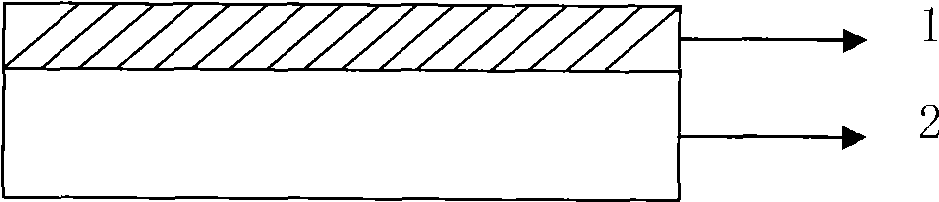

[0020] Such as figure 2 As shown, the BOPP matting film of the present invention has a double-layer structure, consisting of a matting layer 1 and a transparent layer 2, and the components of the transparent layer 2 contain 1.5%wt antistatic agent by weight percentage, and the rest are biaxially stretched grade polypropylene resin; The composition of matting layer 1 is 100%wt matting material. Among them, the transparent layer is corona treated.

[0021] Using biaxially stretched polypropylene resin and matting material to form a two-layer structure film after co-extrusion and biaxial stretching; the matting material melt extruded from two auxiliary extruders is extruded to the same matting layer through a die adapter . It is processed into a transparent layer with a thickness of 10-18 μm and a matte layer with a thickness of 2-4 μm.

Embodiment 2

[0023] Such as figure 2 As shown, the BOPP matting film of the present invention has a double-layer structure, consisting of a matting layer 1 and a transparent layer 2, and the components of the transparent layer 2 contain 2.5%wt antistatic agent by weight percentage, and the rest are biaxially stretched grade polypropylene resin; The composition of matting layer 1 is 99%wt matting material and 1% smoothing agent, and both sides of the film are corona treated.

[0024] Using biaxially stretched polypropylene resin and matting material to form a two-layer structure film after co-extrusion and biaxial stretching; the matting material melt extruded from two auxiliary extruders is extruded to the same matting layer through a die adapter . It is processed into a transparent layer with a thickness of 10-18 μm and a matte layer with a thickness of 2-4 μm.

Embodiment 3

[0026] Such as figure 2 As shown, the BOPP matting film of the present invention has a double-layer structure, consisting of a matting layer 1 and a transparent layer 2, and the components of the transparent layer 2 contain 2%wt antistatic agent by weight percentage, and the rest are biaxially stretched grade polypropylene resin; The composition of matting layer 1 is 100%wt matting material.

[0027] Using biaxially stretched polypropylene resin and matting material to form a two-layer structure film after co-extrusion and biaxial stretching; the matting material melt extruded from two auxiliary extruders is extruded to the same matting layer through a die adapter . It is processed into a transparent layer with a thickness of 10-18 μm and a matte layer with a thickness of 2-4 μm. Both sides of the film are corona treated.

[0028] In the above three examples, since the matting layer of the BOPP matting film is relatively rough, when the matting surface touches the non-matt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com