Klebsiella pneumoniae and method of preparing hydrogen and 2, 3-butanediol thereby

A Klebsiella and butanediol technology, applied in biochemical equipment and methods, microorganism-based methods, bacteria, etc., can solve problems such as environmental pollution, energy shortage, and urgency, and achieve high conversion efficiency and reaction conditions. Simple and easy, high production value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Method for preparing hydrogen and 2,3-butanediol using Klebsiella pneumoniae ECU-21

[0044] The formula of the fermentation medium is: glucose 10g / L, yeast powder 5g / L, peptone 10g / L, beef extract 6g / L, NaCl 5g / L, KH 2 PO 4 0.05g / L, K 2 HPO 4 0.05g / L, pH6.0~6.2; high temperature sterilization at 121℃ for 20min.

[0045] Take the slant strains stored at 4°C, pick a ring and inoculate it into a Erlenmeyer shaker flask containing 30ml of seed medium, and culture it statically at 37°C for 12 hours, then inoculate the seed medium with 5% inoculum to 600ml In the fermentation medium, the fermentation shaker flask was sealed with a rubber stopper, and then N 2Purge to form an anaerobic environment in the reactor, excess gas is discharged from the exhaust port, N 2 After the purge is completed, the air bag is used to connect the exhaust port. The hydrogen generated by the fermentation is collected by the air bag, and samples are taken from the sampling port at regular i...

Embodiment 2

[0047] Method for preparing hydrogen and 2,3-butanediol using Klebsiella pneumoniae ECU-21

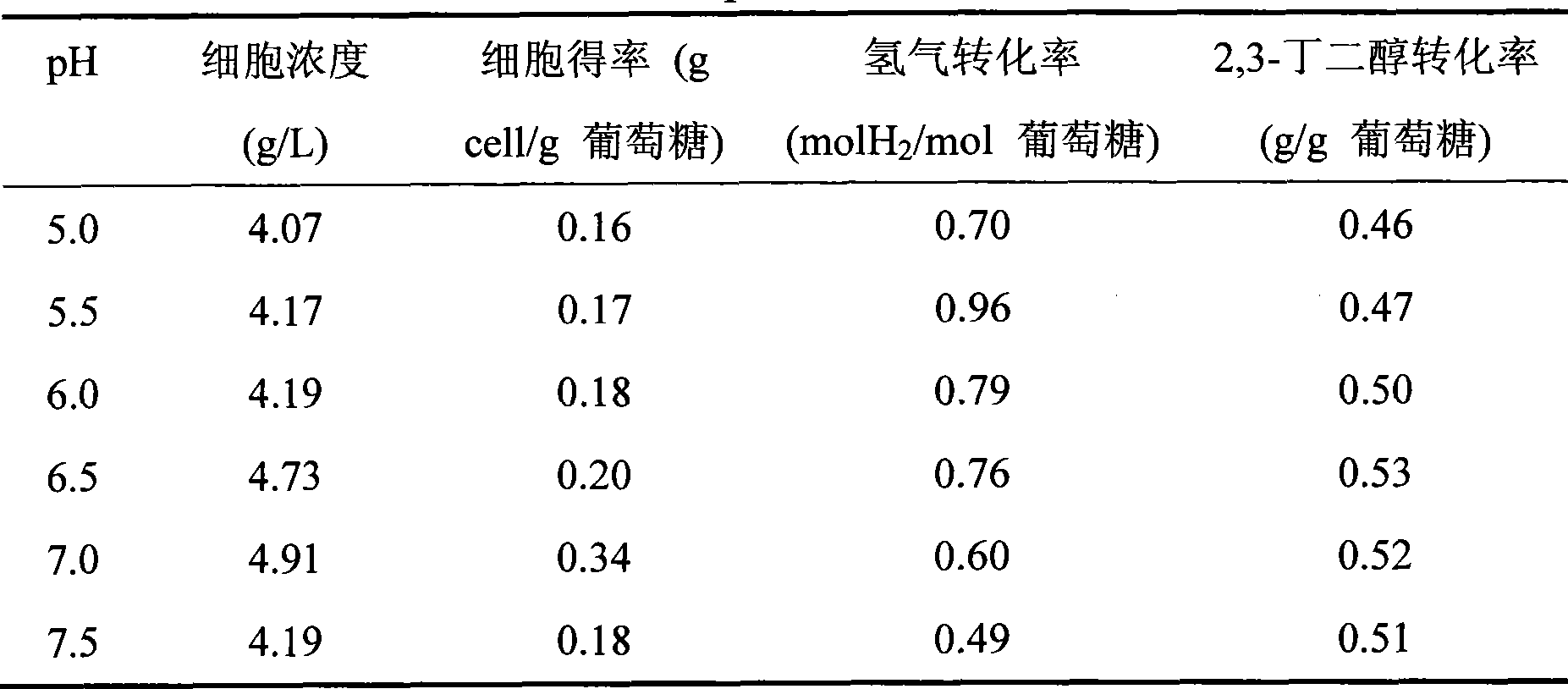

[0048] Fermentation medium formula: glucose 30g / L, yeast powder 5g / L, peptone 10g / L, beef extract 6g / L, NaCl 5g / L, phosphate buffer 200mM, adjust different pH to 5.0~7.5, 121℃ High temperature sterilization for 20min.

[0049] Take the slant strains stored at 4°C, pick one ring and inoculate them into the Erlenmeyer shaker flasks containing 30ml of medium, culture them at 37°C for 12 hours, and transfer them to 600ml flasks according to the inoculation amount of 5%. , in the fermentation media with different pH, use rubber stopper to seal the fermentation shake flask, pass N 2 The air in it is exhausted to form an anaerobic environment, and the excess gas is discharged from the exhaust port, N 2 After purging, a gas bag was used to connect the exhaust port to collect the hydrogen produced by fermentation. The culture temperature was kept at 37°C, and a magnetic stirrer was used to st...

Embodiment 3

[0053] Method for preparing hydrogen and 2,3-butanediol using Klebsiella pneumoniae ECU-21

[0054] The fermentation medium is the hydrolyzate obtained by enzymatic hydrolysis of corn stalks after steam expansion pretreatment. The main composition of the hydrolyzate is: glucose 60g / L; xylose 12g / L; cellobiose 4g / L; the hydrolyzate is diluted 6 times, Add yeast powder 5g / L, peptone 10g / L, beef extract 6g / L, NaCl 5g / L, phosphate buffer 200mM, pH 6.0-6.2, and sterilize at 115°C for 20min.

[0055] The seed culture medium is the same as that in Example 1. Get the slant strains preserved at 4°C, pick a ring and inoculate it into a triangular shaker flask with 30ml of seed culture medium, and cultivate it statically at 37°C for 12 hours, and inoculate at 5%. The amount was transferred to a 1L fermentation shaker flask filled with 600ml of fermentation medium, sealed with a rubber stopper, and passed through N 2 Exhaust the air in it, and the excess gas is discharged from the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com