Double-rotor four-stroke spark ignition internal combustion engine

A dual-rotor, four-stroke technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of low efficiency, low reliability and severe vibration of internal combustion engines, and achieve improved output power, high reliability and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following embodiments illustrate the dual-rotor four-stroke ignition internal combustion engine of the present invention without limitation in conjunction with the accompanying drawings. Those of ordinary skill in the art can also make various changes and modifications without departing from the spirit and scope of the present invention, so all equivalent technical solutions also belong to the category of the present invention, and its patent protection scope It is defined by the claims of this application.

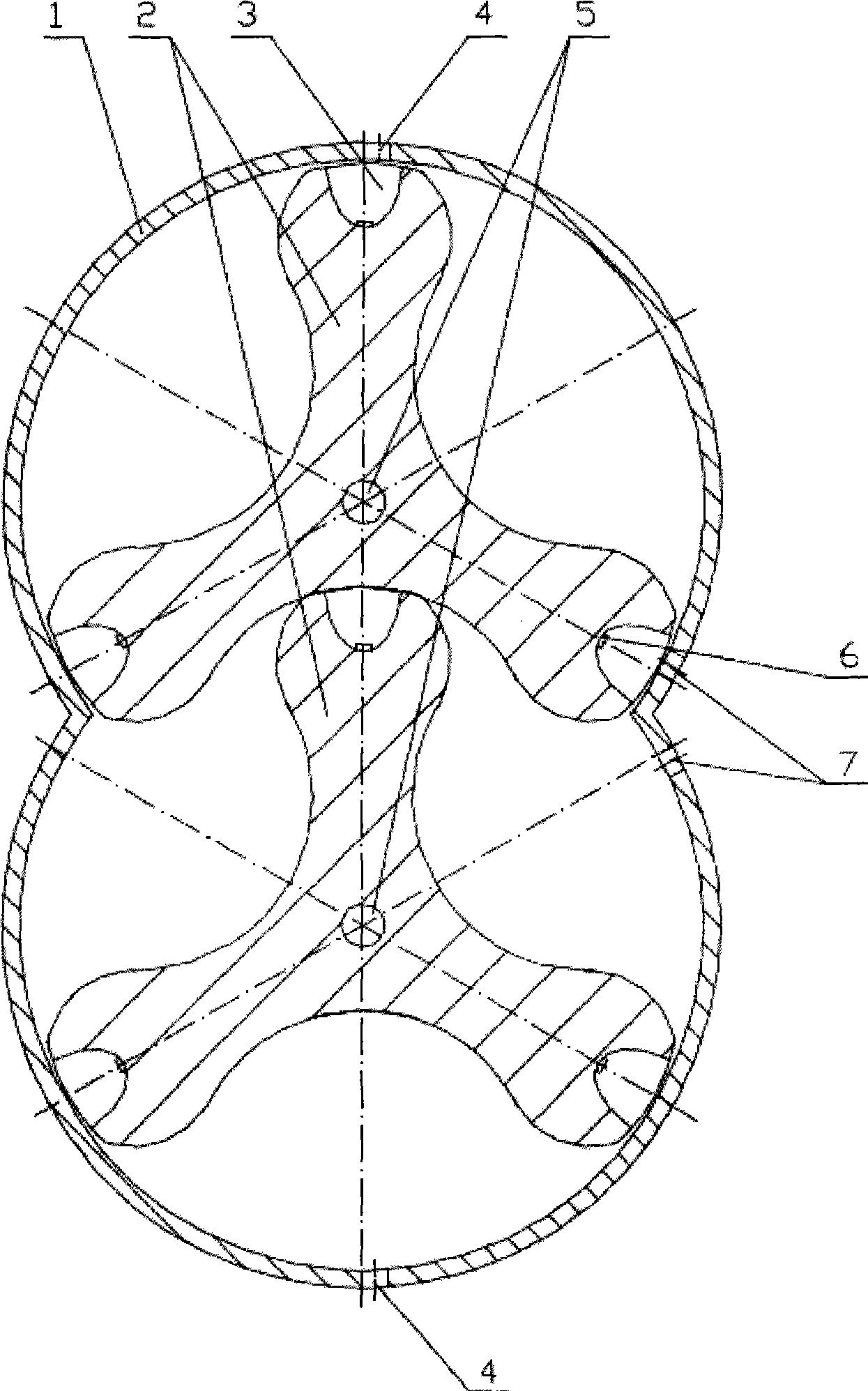

[0015] Such as figure 1 , 2 , 3, two three-lobed rotors 2 are installed side by side inside the cylinder block 1 of the internal combustion engine. The two ends of the long axis of the cylinder body 1 are respectively provided with two air inlets 4, and two air outlets 7 are opened on the right side rib. A concave combustion chamber 3 is provided at the end of the rotor blade, and when the internal combustion engine is working, the combustion chamber stores ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com