Wind power generation chimney

A technology of generators and round tubes, which is applied in wind power generation, wind power engines, wind power motor combinations, etc., can solve problems such as insufficiency, and achieve the effect of large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

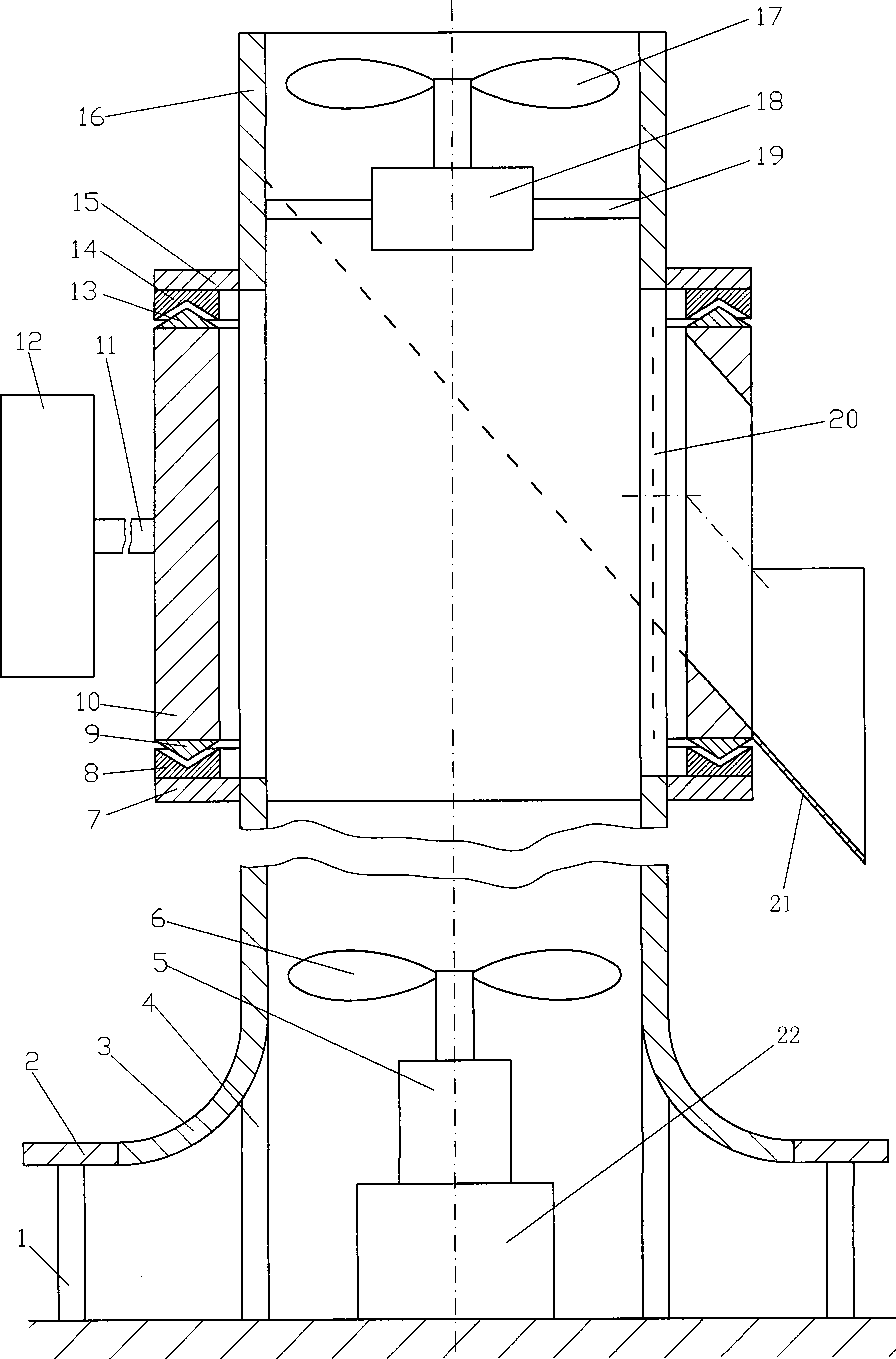

Embodiment 1

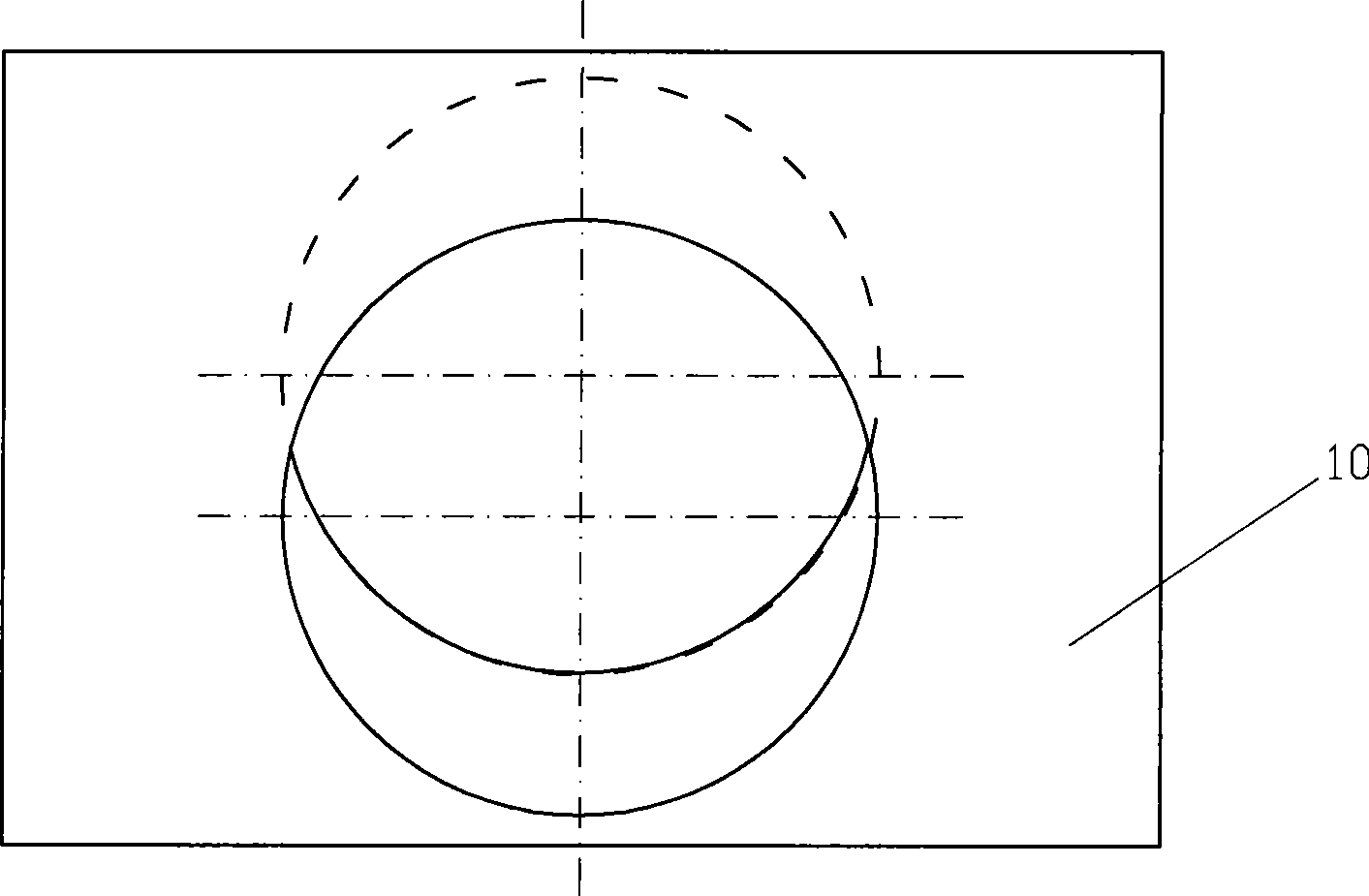

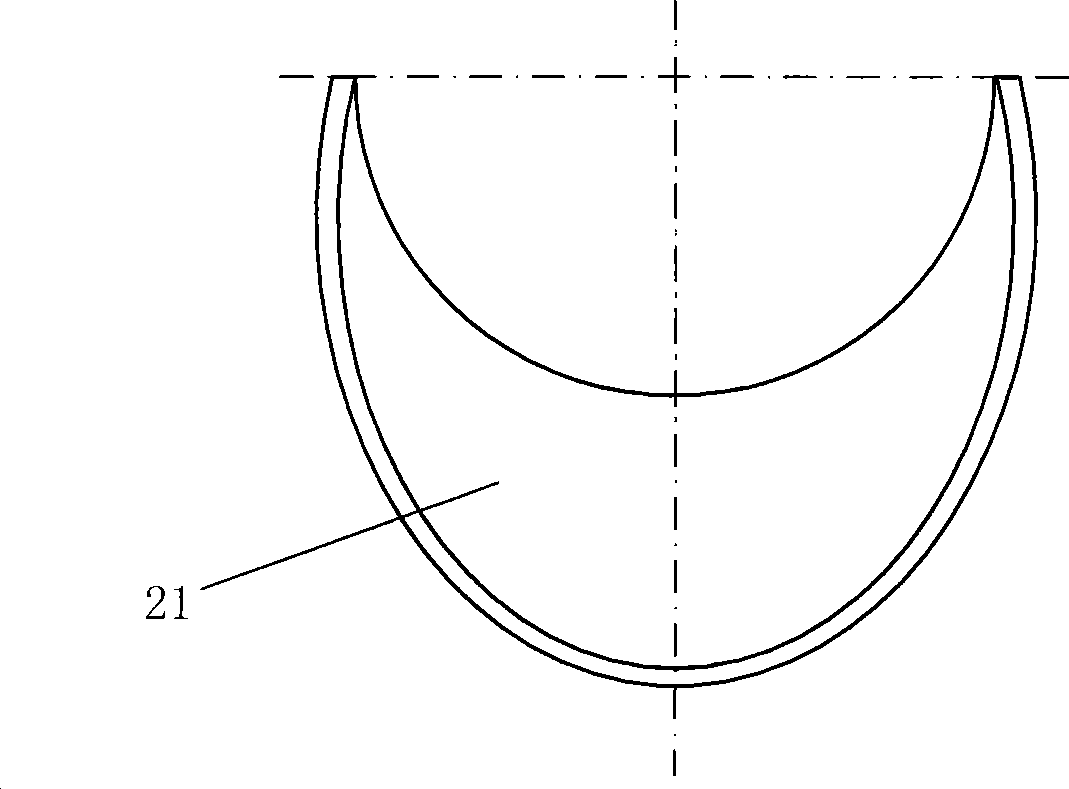

[0023] Embodiment one: if Figure 1 to Figure 3 Show. The pipe diameter of the vertical circular pipe 3 is made to be the same size up and down or made to be small at the top and large at the bottom. The vertical circular pipe 3 is connected and supported by several columns 4 fixed on the foundation; the circular heat collecting plate or current collecting plate 2 is composed of several A column 1 fixed on the foundation is connected and supported, and is sleeved on the lower edge of the vertical circular tube 3. The circular heat collecting plate is made of transparent material, allowing sunlight to transmit and heat the air below. The circular collecting plate is used Made of other materials to collect hot air; the circle 7 is sleeved on the outer circle of the upper end of the vertical pipe 3, the circle 15 is sleeved on the outer circle of the lower end of the vertical pipe 16, and the upper end of the circle 7 is consolidated into a V-ring groove shaped along the vertical ...

Embodiment 2

[0024] Embodiment two: if Figure 4 Show. When wind or updraft speed is small, or it is not easy to install support 19, generator 18 and impeller 17, etc., spoke-shaped support 19, generator 18 and impeller 17 can be removed, and impeller 6 drives generator 5 to generate electricity.

Embodiment 3

[0025] Embodiment three: as Figure 5 Show, under certain circumstances, such as in order to alleviate the harm of noise, can remove pad 22, generator 5 and impeller 6, drive generator 18 to generate electricity with impeller 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com