Method for producing terephthalic acid-alkylene glycol mixture

A technology for terephthalic acid and dialkyl phthalate, which is applied in the field of preparation of mixtures, can solve the problems of easy particle size variation of terephthalic acid and narrow operating conditions, and achieves reduced equipment costs, good stability, The effect of low slurry viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of terephthalic acid

[0030] As long as the terephthalic acid in the present invention is obtained by hydrolyzing a dialkyl terephthalate, hydrolysis conditions and the like are not limited, and can be used in the method of the present invention. Dialkyl terephthalates include dimethyl terephthalate, diethyl terephthalate, dipropyl terephthalate, dibutyl terephthalate, dibutyl terephthalate, hexyl ester.

[0031]Among them, it is preferred to use dimethyl terephthalate as a starting material, the reaction temperature of the hydrolysis reaction is 180-300°C, preferably 230-260°C, and the pressure at this time is preferably 2.8-4.6MPa (gauge pressure), Terephthalic acid obtained by reacting under high temperature and high pressure. It is known that a high reaction rate can be achieved by shifting the reaction equilibrium to the product side by discharging the by-product mainly composed of methanol produced during the hydrolysis reaction as vapor out of the...

Embodiment 1

[0053]Dimethyl terephthalate and pure water were put into a batch reactor equipped with a stirrer, and heated. After the liquid temperature reaches 250°C, open the distillation pipe valve set on the upper cover of the reactor to distill and remove the by-product methanol and water vapor produced by the hydrolysis reaction, and at the same time, continuously supply and distill it to the reactor the same amount of water as the water. After a predetermined period of time, while continuing to distill and remove methanol, lower the temperature of the liquid in the reactor to 230°C, keep the temperature for 30 minutes, and let the liquid in the reactor flow through the internal liquid outlet pipe for a moment. The reaction solution was cooled in a container at atmospheric pressure. By controlling the operating conditions during the hydrolysis reaction, the ratio of the mass of reaction water to the mass of terephthalic acid was set to 1.0 in the state of the reaction liquid before ...

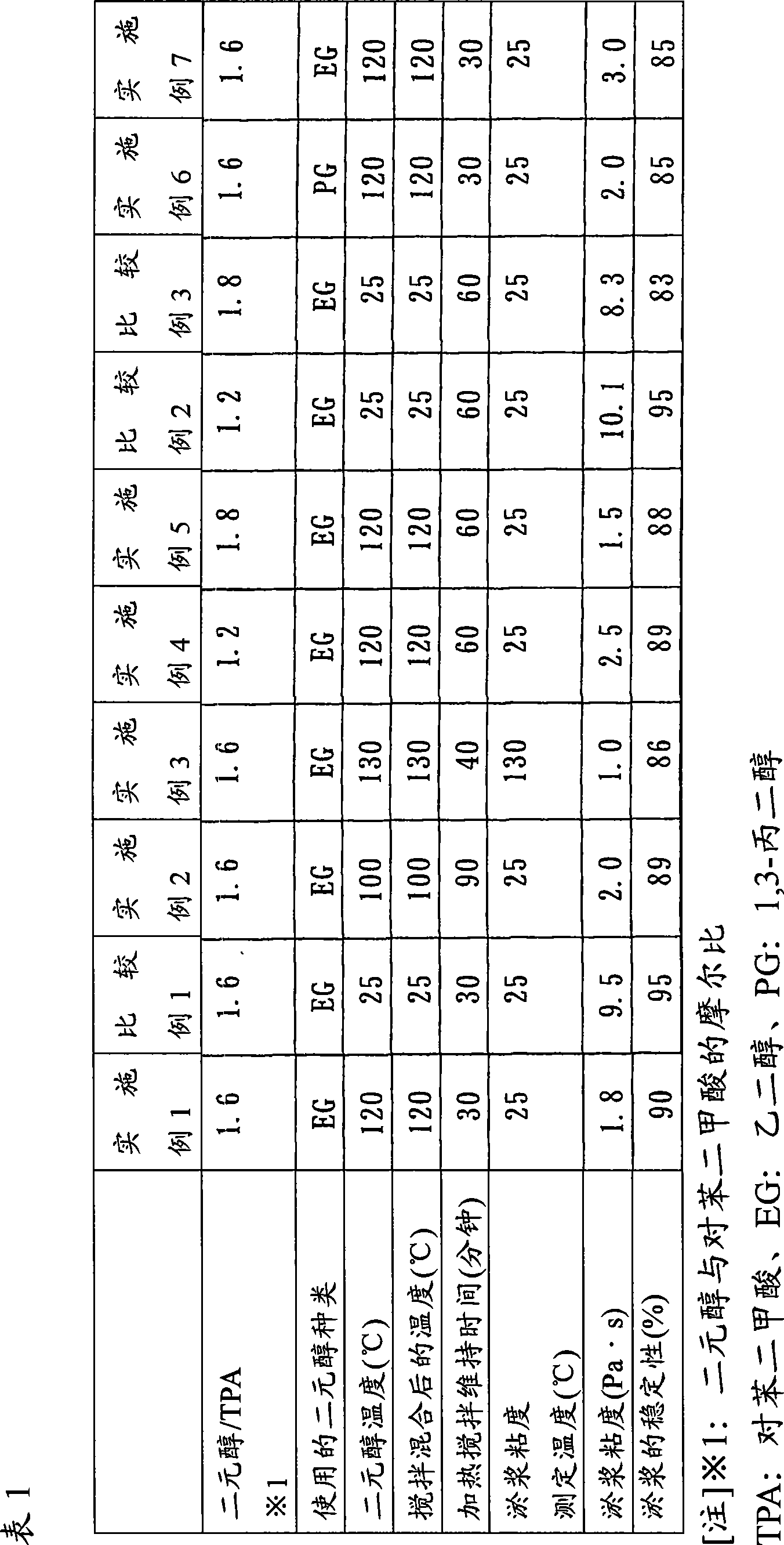

Embodiment 2~5、 comparative example 2~3

[0059] In Examples 2 to 5 and Comparative Examples 2 to 3, 1 part by mass of dimethyl terephthalate and 1 part by mass of water were continuously supplied to the first reaction tank using four continuous tank reactors connected in series, respectively. In the process, the hydrolysis is carried out at the temperature of each tank in the range of 220 to 255° C. and the pressure in the range of 2.3 to 4.5 MPa. Further, after the obtained reaction mixture is directly and rapidly cooled to return to atmospheric pressure, the obtained slurry containing terephthalic acid is separated from solid and liquid by a centrifuge to obtain terephthalic acid. The water content of terephthalic acid was 18% by mass. The obtained terephthalic acid had an average particle diameter of 131 μm, and fine particles having a particle diameter of 45 μm or less accounted for 14% by mass. The obtained terephthalic acid was used directly without drying, except that the ratio of ethylene glycol to terephtha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com