Palladium-cobalt based alloys and dental articles including the same

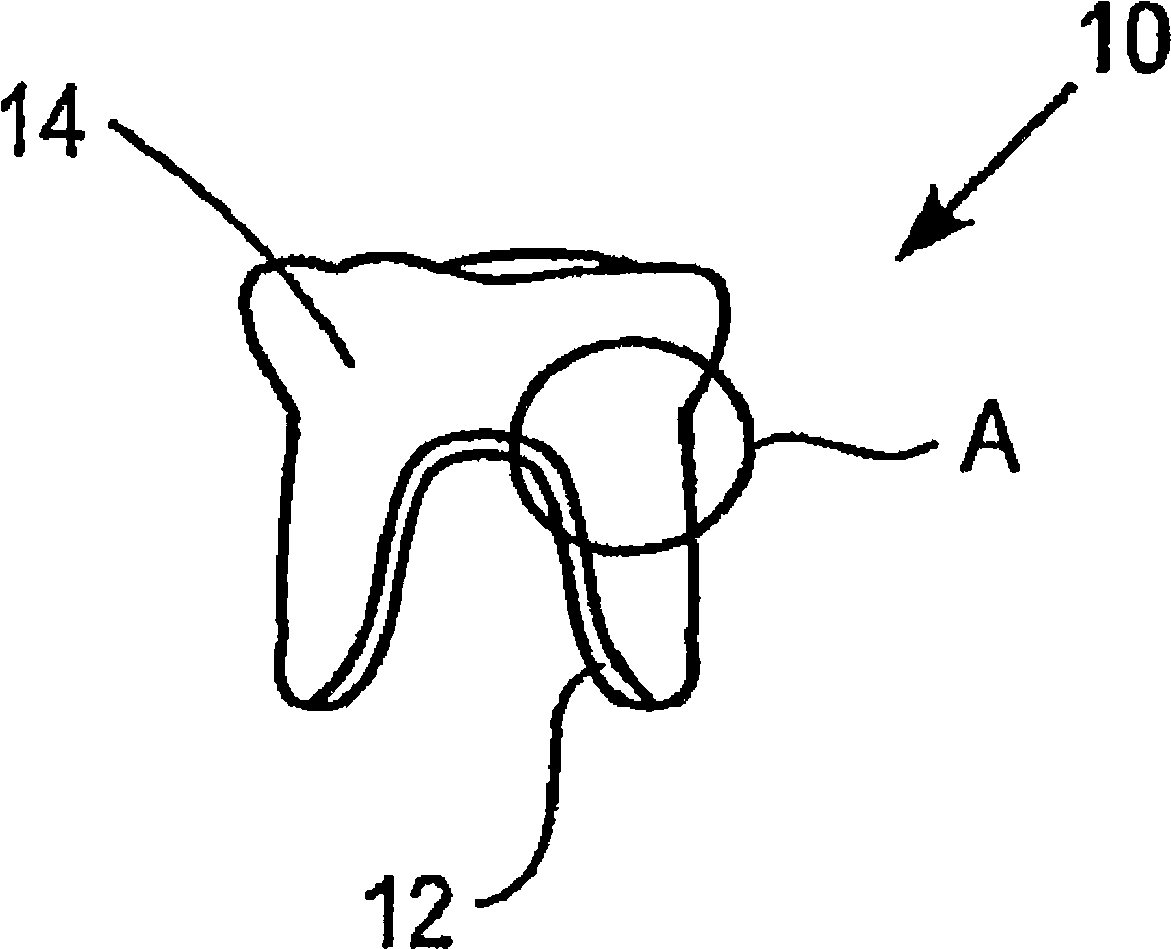

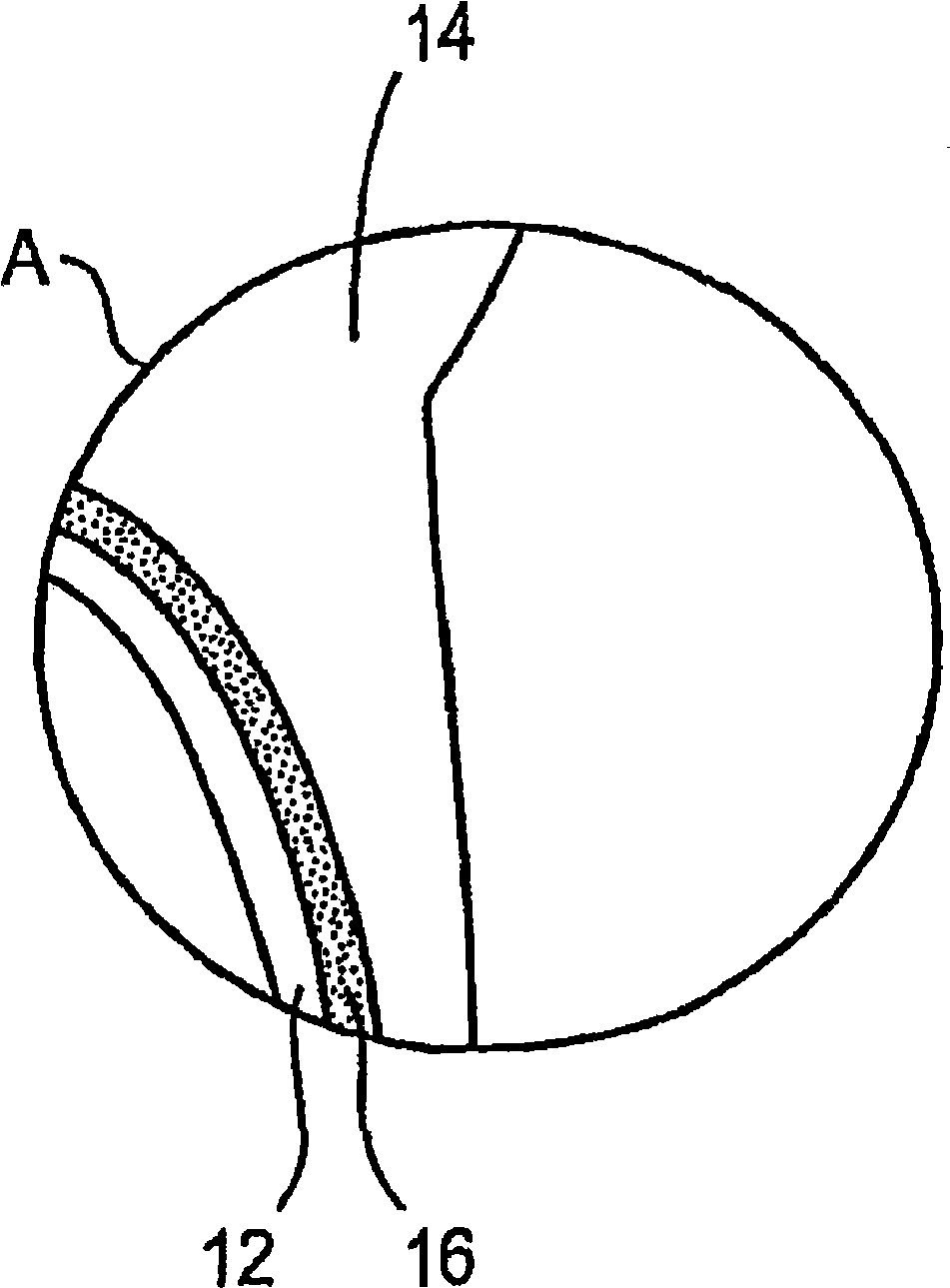

A technology for alloys and products, applied in the field of novel palladium-cobalt-based alloys, can solve problems such as cracking of ceramic layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7

[0037] Examples 1 to 7 (coefficient of thermal expansion (CTE))

[0038] In order to successfully use the alloys of the present invention with contemporary used porcelains, the CTE should be in the range of about 14.0 to about 15.3. When two metals comprise the base metal of the alloy, the CTE of the alloy is expected to be between the CTEs of the two metals. It has been determined that this does not necessarily apply to palladium cobalt alloys. Given that palladium (Pd) has a CTE of 12.5 and cobalt (Co) has a CTE of 11.75, alloys of the invention including palladium / cobalt (Pd / Co) alloys have larger values, as described in the following examples, where The listed amounts are in percent by weight:

[0039] Table 1

[0040] Example number 1 2 3 4 5 6 7 PD 10 20 30 40 50 70 90 co 90 80 70 60 50 30 10 CTE 13.85 14.0 14.1 14.6 14.9 15.2 14.2

Embodiment 8 to 12

[0041] Embodiments 8 to 12 (fixed wire)

[0042] The minimum solidus temperature of the alloy of a particular embodiment of the invention was determined to be about 1025°C so that the alloy would not start to melt during casting on its surface as a ceramic.

[0043] Table 2

[0044] Example number 8 9 10 11 12 PD 65 33.8 61.8 27.0 28.2 co 35 60.4 31.0 52.3 56.0 Cr 1.2 16.2 10.0 Mo 2.4 2.0 Si 1.0 0.7 0.6 0.05 Fe 0.3 W 3.0 Ga 2.0 Al 1.2 1.6 0.35

[0045] Ta 0.8 Nb 3.0 Re 0.6 Ru 0.6 0.8 0.5 Li 0.1 0.1 0.2 B 0.2 Solid line temperature

[0046] Alloys 9 and 10 did not exhibit an unsatisfactory minimum solidus temperature.

Embodiment 13

[0048] Type: Precious Metal Porcelain / Type 4 / ISO9693

[0049] 31-VI

[0050] Composition: palladium: 28+ / —0.8%; cobalt: 55-58%; chromium: 8.0-11.0%; tungsten: 2.5-4.0%; gallium: 1.0-2.5%; (aluminum, silicon, boron and lithium: < 1.0%).

[0051] Concentration: 9.0gm / cc

[0052] Color: Crucible:

[0053] white ceramic

[0054] Complete combustion temperature: 750-820°C (1380-1510°F)

[0055] Casting temperature: 1410-1460°C (2570-2660°F)

[0056] Melting temperature: 1100-1350°C (2010-2460°F)

[0057] Oxidation period: 925°C / 5 minutes / air

[0058] Porcelain compatibility: Dizan fluorohydroxyapatite low-temperature nano-ceramic powder (IPS d.Sign); Ivoclar classic ceramic powder and new leucite medium-temperature ceramic powder (IPS Classics & Inline)

[0059] Tensile properties:

[0060] The ultimate tensile stress (U.T.S) deviates from the elastic hardness of the practical elastic limit stress (Proof Stress) elongation modulus 0.2%:

[0061] C.T.E:@25-500℃@20-600℃

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com