Killing method of colibacillus

A technology of Escherichia coli and low-temperature plasma, which is applied in the direction of sanitary equipment, plasma, and electrical components used in toilets, can solve the problems of easy drug resistance, achieve low temperature, and avoid degradation and denaturation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

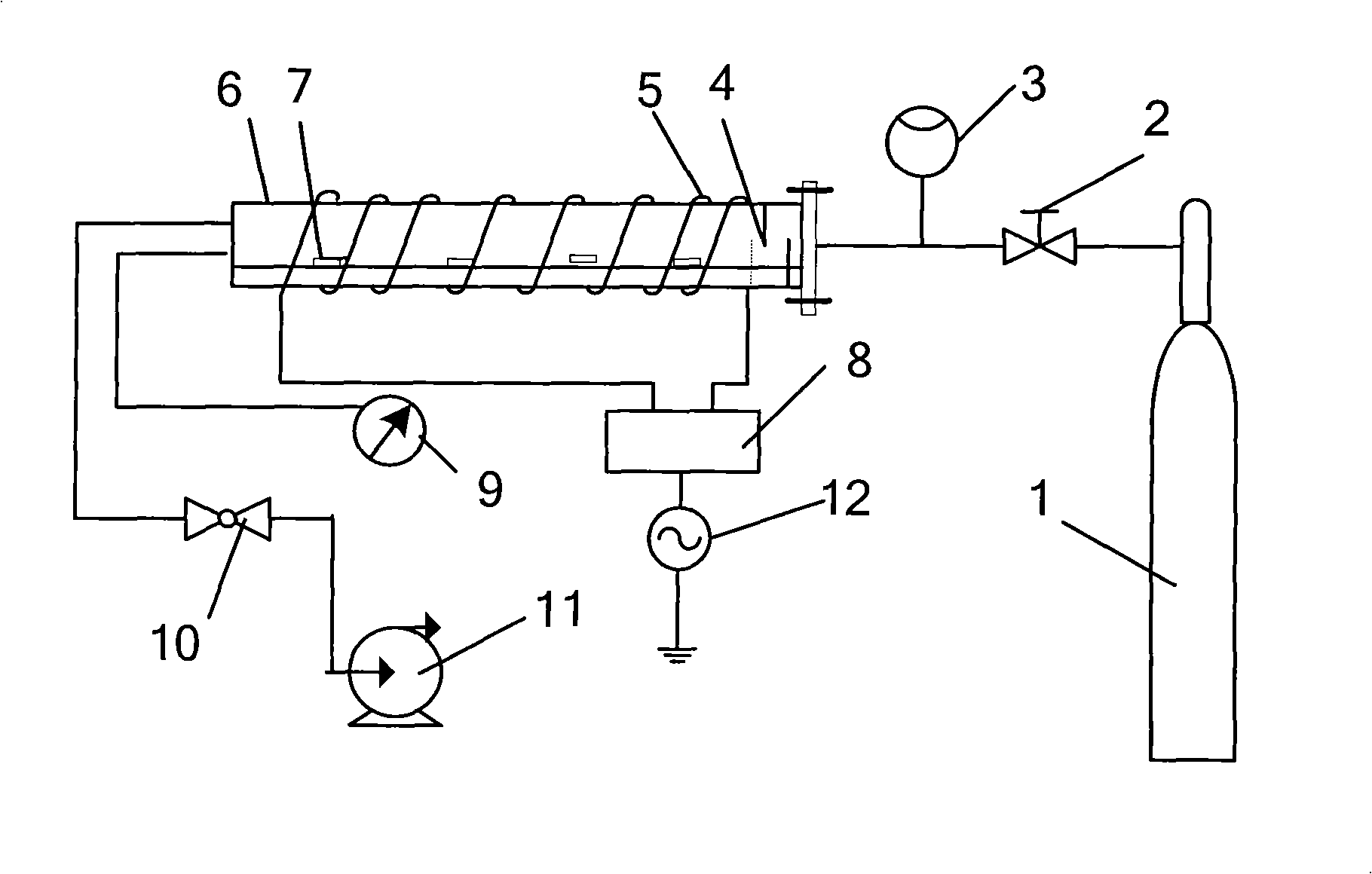

Method used

Image

Examples

experiment example 1

[0021] First, draw 10 μl of freshly prepared E. coli suspension and spread it evenly on the treated PTFE slide, after drying, place it in the discharge reaction tube of the radio frequency plasma discharge device. PTFE is polytetrafluoroethylene, which is a common medical polymer material. It is often used in the manufacture of artificial hearts, artificial valves, artificial larynx, artificial blood vessels, and various medical catheters.

[0022] Then, adjust the discharge parameters of the radio frequency plasma discharge device as follows: the working gas is oxygen, the discharge power is 100W, and the gas flow rate is 60cm 3 / min, voltage 440V, current 105mA, background vacuum 7.0Pa; the sterilization effect after 30s is 3.5, and the sterilization rate is 99.97%; it tends to be stable after 80-90s, and the sterilization reaction is close to complete after 90s; at this time, The plasma temperature was up to 32°C. Among them, the sterilization effect is calculated by the f...

experiment example 2

[0024] First, draw 10 μl of freshly prepared E. coli suspension and spread it evenly on the treated PTFE slide, after drying, place it in the discharge reaction tube of the radio frequency plasma discharge device.

[0025] Then, adjust the discharge parameters of the radio frequency plasma discharge device as follows: the working gas is oxygen, the discharge power is 100W, and the gas flow rate is 60cm 3 / min, voltage 440V, current 105mA, background vacuum 7.0Pa; the sterilization effect after 60s is 3.9, and the sterilization rate is 99.99%; it tends to be stable after 80-90s, and the sterilization reaction is close to complete after 90s; at this time, The plasma temperature was up to 33°C.

experiment example 3

[0027] First, draw 10 μl of freshly prepared E. coli suspension and spread it evenly on the treated PTFE slide, after drying, place it in the discharge reaction tube of the radio frequency plasma discharge device.

[0028] Then, adjust the discharge parameters of the radio frequency plasma discharge device as follows: the working gas is oxygen, the discharge power is 100W, and the gas flow rate is 90cm 3 / min, voltage 440V, current 105mA, background vacuum 7.0Pa; the sterilizing effect was 4.1 in 90s, and the sterilizing rate was 99.99%; the sterilizing reaction was nearly complete after 90s; at this time, the highest plasma temperature was 37°C.

[0029] Experimental examples 1-3 illustrate that low-temperature oxygen plasma can effectively kill Escherichia coli in a short time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com