Fixed bed reactor

A fixed bed reactor and reactor technology, which is applied in chemical instruments and methods, pressure vessels used in chemical processes, chemical/physical processes, etc. Reactor heat transfer efficiency and other issues, to achieve the effect of good acid and alkali corrosion resistance, uniform heating, solving material and processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

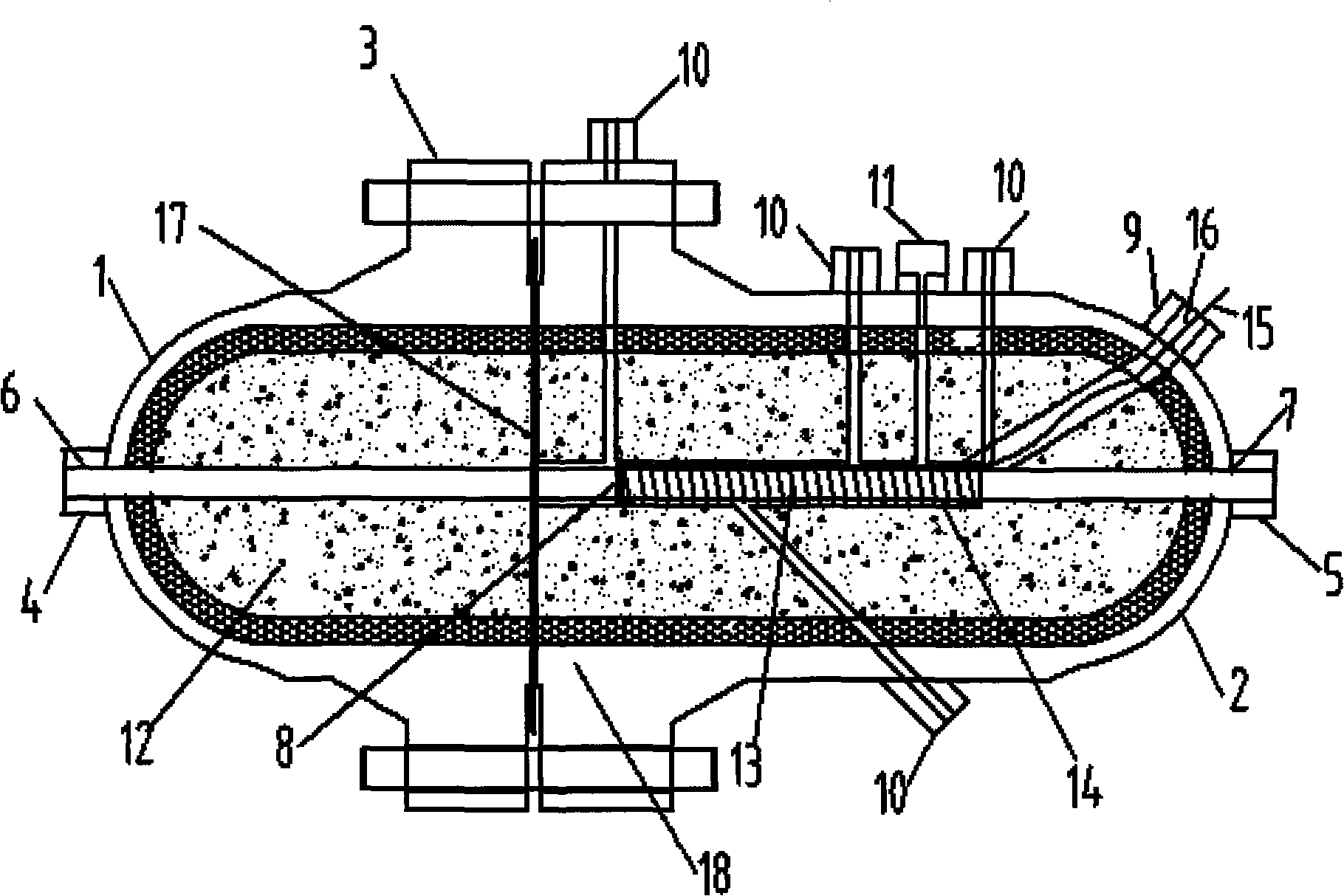

[0015] Implement the fixed bed reactor of the present invention, including the molding method of the fixed bed reactor, and the processing method for the shell formed by the flanged cylinder and the head, and the material for making the reactor shell adopts 0Cr18Ni9 , cylinder diameter is 370mm, wall thickness is 40mm. Both the head I and the head II adopt the spherical head with the best force and are welded to the cylinder body. The central end of the head I is welded with the reaction gas outlet pipe 4 and connected to the flange. The central end of the head II is welded with a reaction gas inlet pipe 5 and connected to a flange. A flange 3 is arranged on the cylinder body, and a quartz reaction tube 7 with a diameter of 37 mm and a length of 1000 mm is arranged in the center of the housing 18 on the right side of the flange sealing surface 17 in the flange 3, and one end thereof reaches the flange sealing surface 17, And communicate with the inner chamber of the reactor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com