Control method and full-servo control system for operating multi-axis mechanical arm

A servo control system and robotic arm technology, applied in the field of full servo control system, can solve problems such as single operation mode of mechanical digital control function, short execution cycle, fault handling time, system abnormality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In this embodiment, its input power supply specification is: 3Φ220VAC 50~60Hz; the power consumption is set according to the model; the control power supply specification: AC input: 170~264VAC, DC output: DC24V3A, DC5V6A; the operating environment temperature Keep at 0-60°C, keep the operating environment humidity at 35%-90%, and keep the storage environment temperature at -5-60°C.

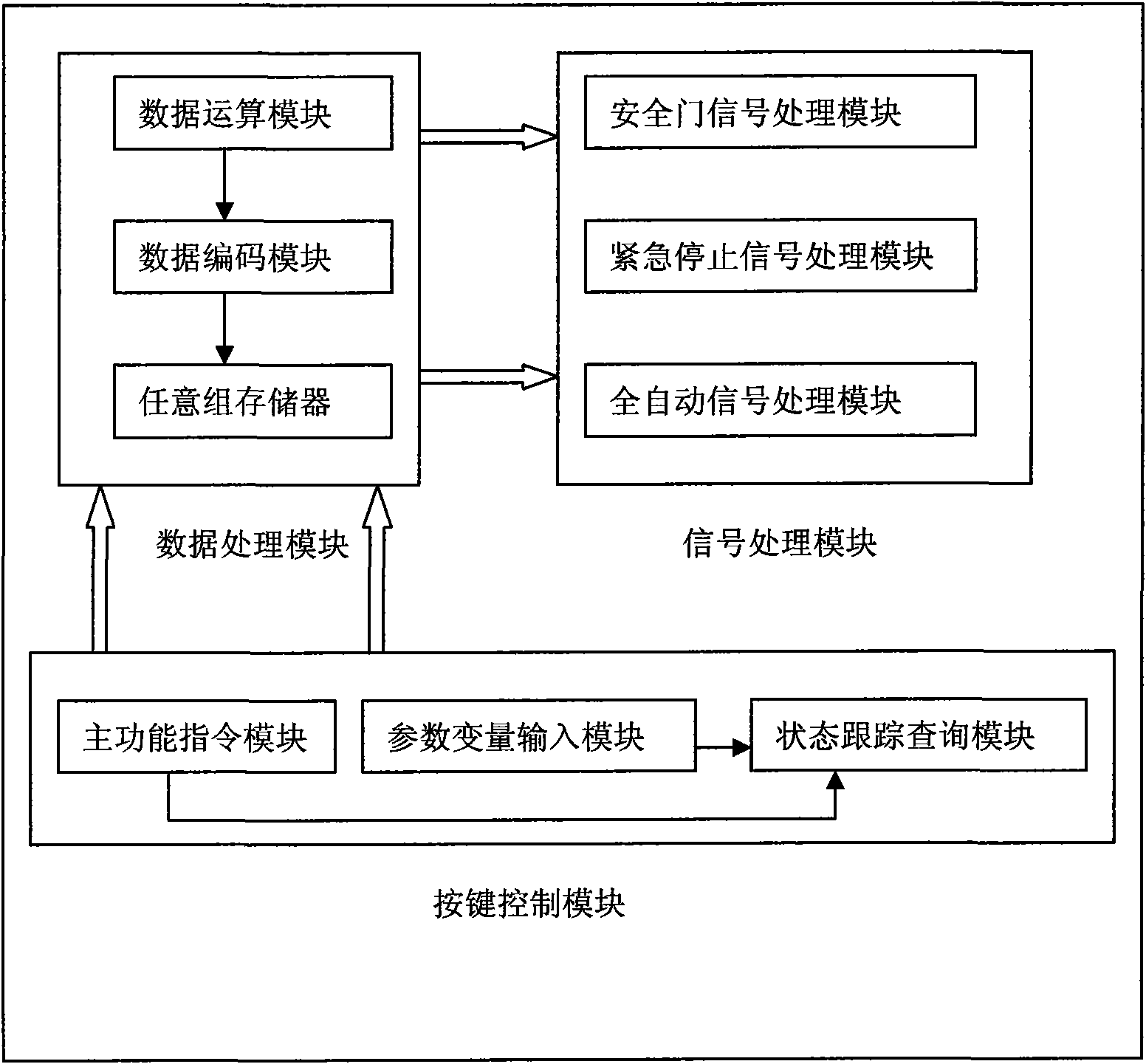

[0025] In this embodiment, all logical operation instructions and their usage are represented by general formulas and unit icons in the industry. The setting category of the value and its operation type are combined with its logical operation instructions, and must be public variable numbers and set to specify their value ranges. Scope, there is no need for a special description except for a special definition.

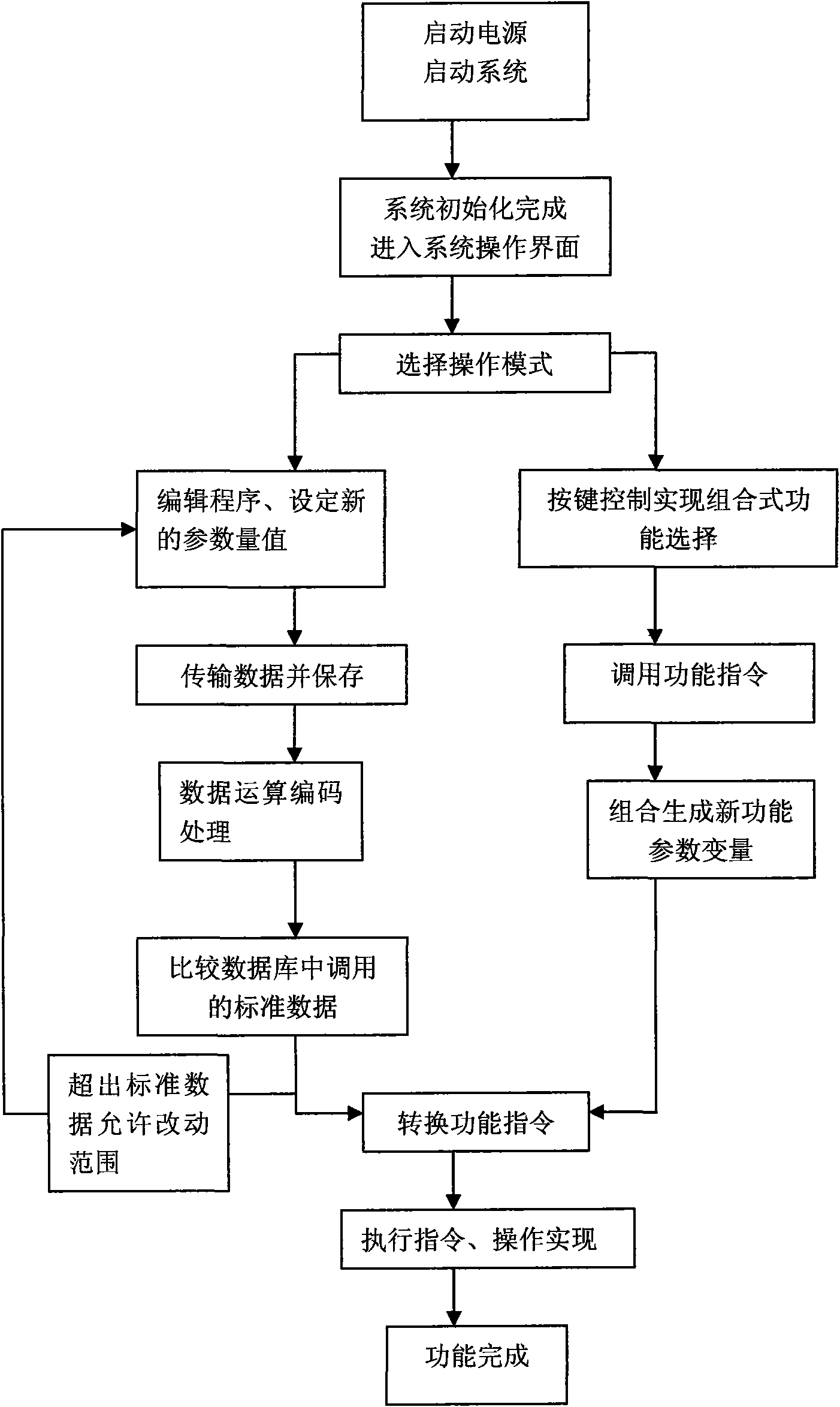

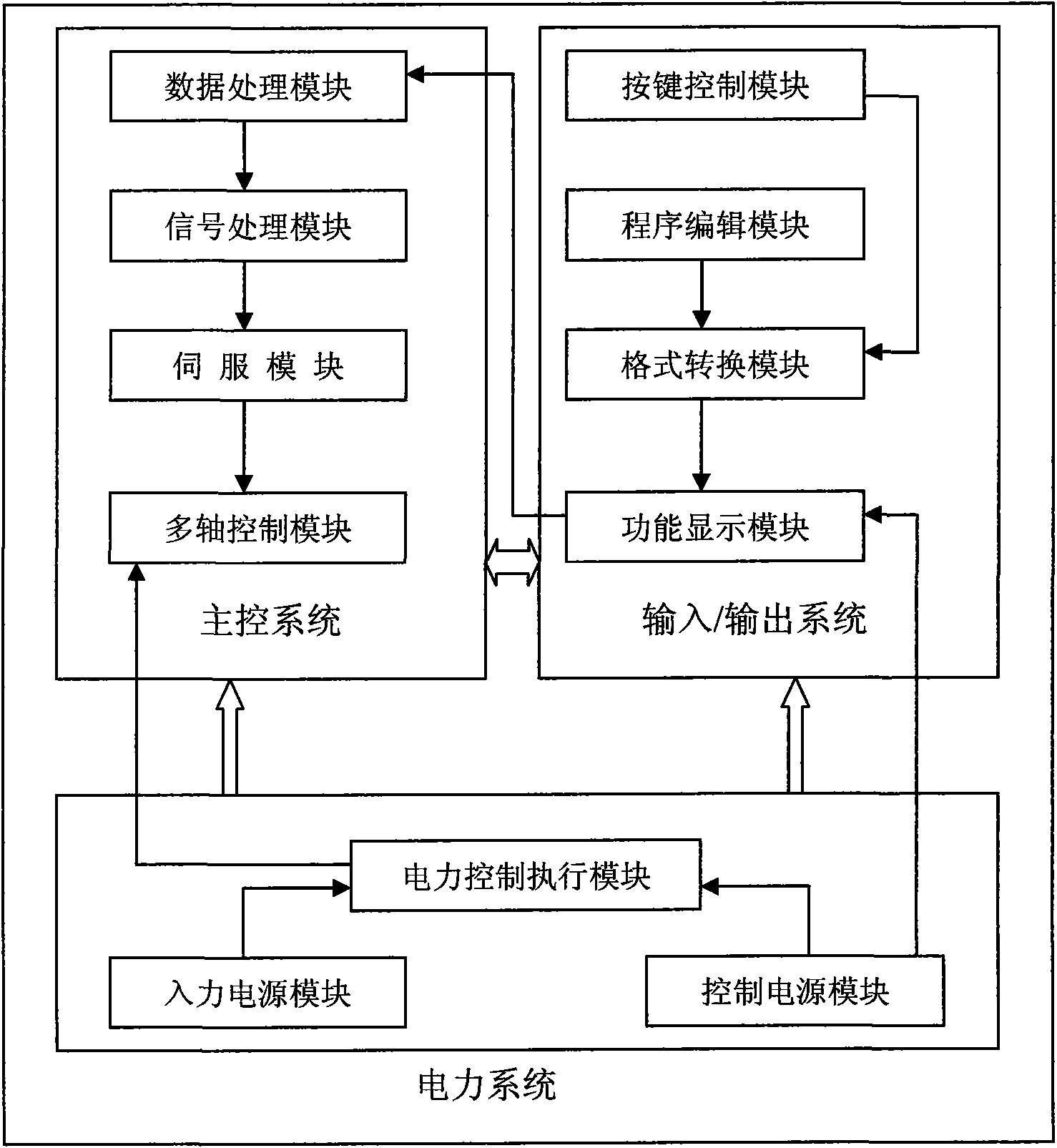

[0026] see figure 1 , a control method for operating a multi-axis robotic arm, which includes a robotic arm body, an ELC-2202 controller, an 8.4” color touch screen, and an axis p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com