Amorphous alloy and preparation method thereof

A technology for ingot casting of amorphous alloys and master alloys, which is applied in the fields of high toughness and easy-to-prepare amorphous alloys and their preparation and high strength. It can solve the problems of high preparation conditions, low strength, and low toughness, and achieve raw materials Reduced requirements for purity and vacuum, good amorphous-forming ability, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing an amorphous alloy, the method comprising the following steps: a method for preparing an amorphous alloy, the method comprising the steps of:

[0018] 1), batching: take Cu, Zr, M and Be according to Cu:Zr:M:Be=a:b:c:d and carry out batching;

[0019] 2) Ingot casting: Vacuumize the melting furnace to a vacuum degree of 10 -2 -10 3 Pa, the raw materials after step 1) are mixed uniformly, and smelted, with 10-10 4 Cooling at a cooling rate of K / s to obtain a master alloy ingot;

[0020] 3), forming: the master alloy ingot obtained in step 2) is melted, and the conventional forming method is used for 10-10 4 K / s cooling rate cooling molding;

[0021] Wherein, M is one or more elements among transition group metals except Cu and Zr, Al, Sn and Si. a, b, c, d are mole percentages and a+b+c+d=100; 15≤a≤45, 10≤b≤50, 5≤c≤35, 0≤d≤30, preferably 30≤a ≤45, 30≤b≤50, 5≤c≤25, 0.01≤d≤10.

[0022] The melting temperature is 1500-250...

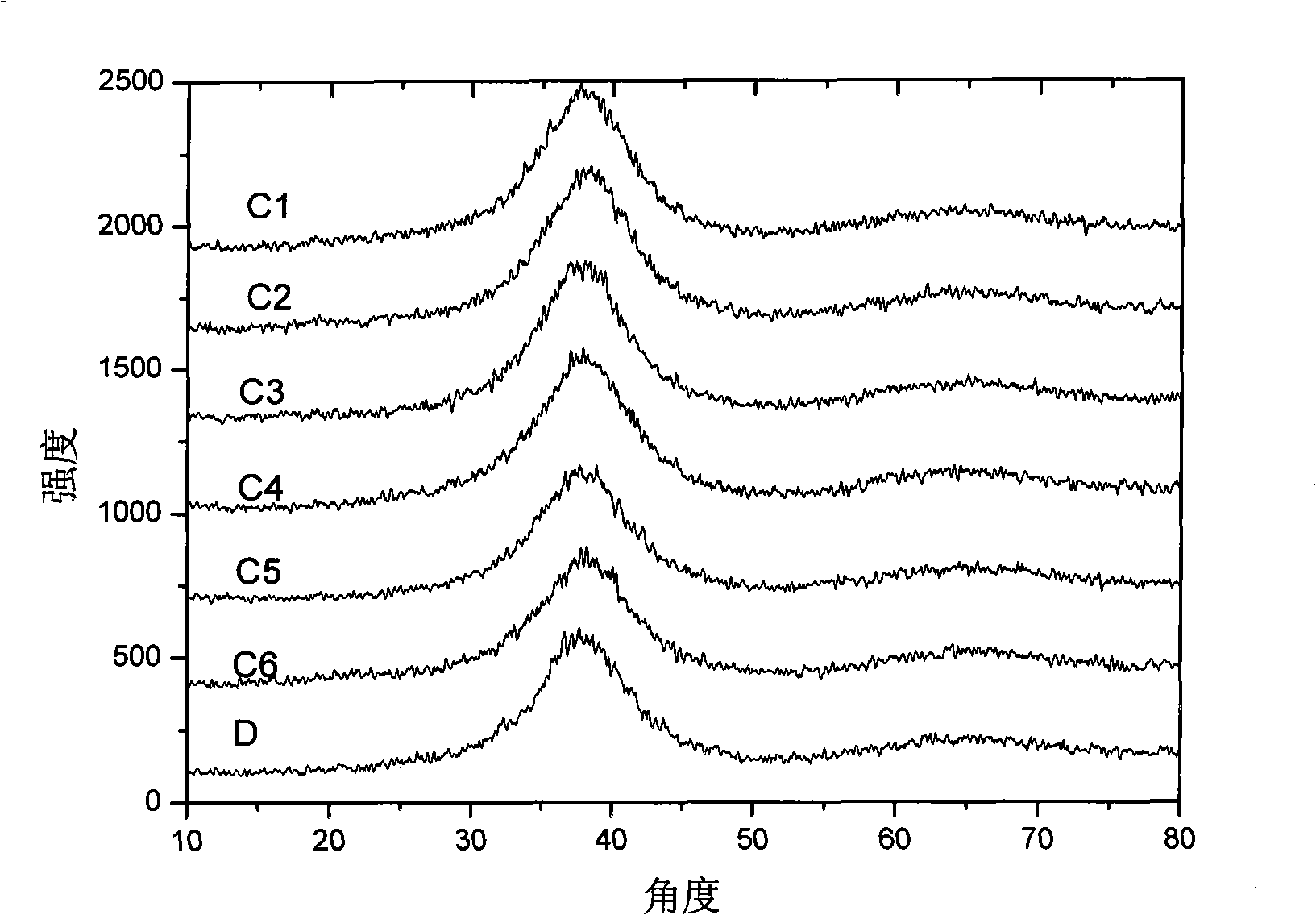

Embodiment 1

[0028] A total of 25g of Cu, Zr, Ti, Al, and Y with a purity of 99.6wt% was placed in an electric arc melting furnace according to the ratio of Cu:Zr:Ti:Al:Y=44:45:2:7:2 and evacuated to 50Pa , into the argon, under the condition of 2000 ℃ for melting, melting time 20-50s, fully stirred and then cooled into ingots, cooling speed 10 4 K / s, melted by arc heating at 2000°C and cooled at a rate of 10 4 K / s is cast into an alloy sample C1 with a size of 3*10*100mm in a beryllium copper mold.

Embodiment 2

[0030] A total of 200kg of Cu, Zr, Al, Ti, and Be with a purity of 99.6wt% is placed in an induction melting furnace according to the ratio of Cu:Zr:Al:Ti:Be=43:45:7:2:2 and evacuated to 100Pa , into nitrogen, smelting at 1500°C for 20 minutes, fully stirred and cooled at a cooling rate of 102K / s to form an ingot, melted by resistance heating at 1800°C and cooled at a cooling rate of 103K / s using stainless steel Alloy sample C2 with a size of 3*10*100mm was produced by die casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com