Thick oil thermal extraction saturated steam flow metering method

A heavy oil thermal recovery and steam flow technology, applied in the fields of fluid production, measurement, earthwork drilling, etc., can solve problems such as the inability to calculate the flow rate of a single well, the inability to meet the measurement conditions and measurement requirements, and the large in and out of steam flow, and the use of The effect of convenience, simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

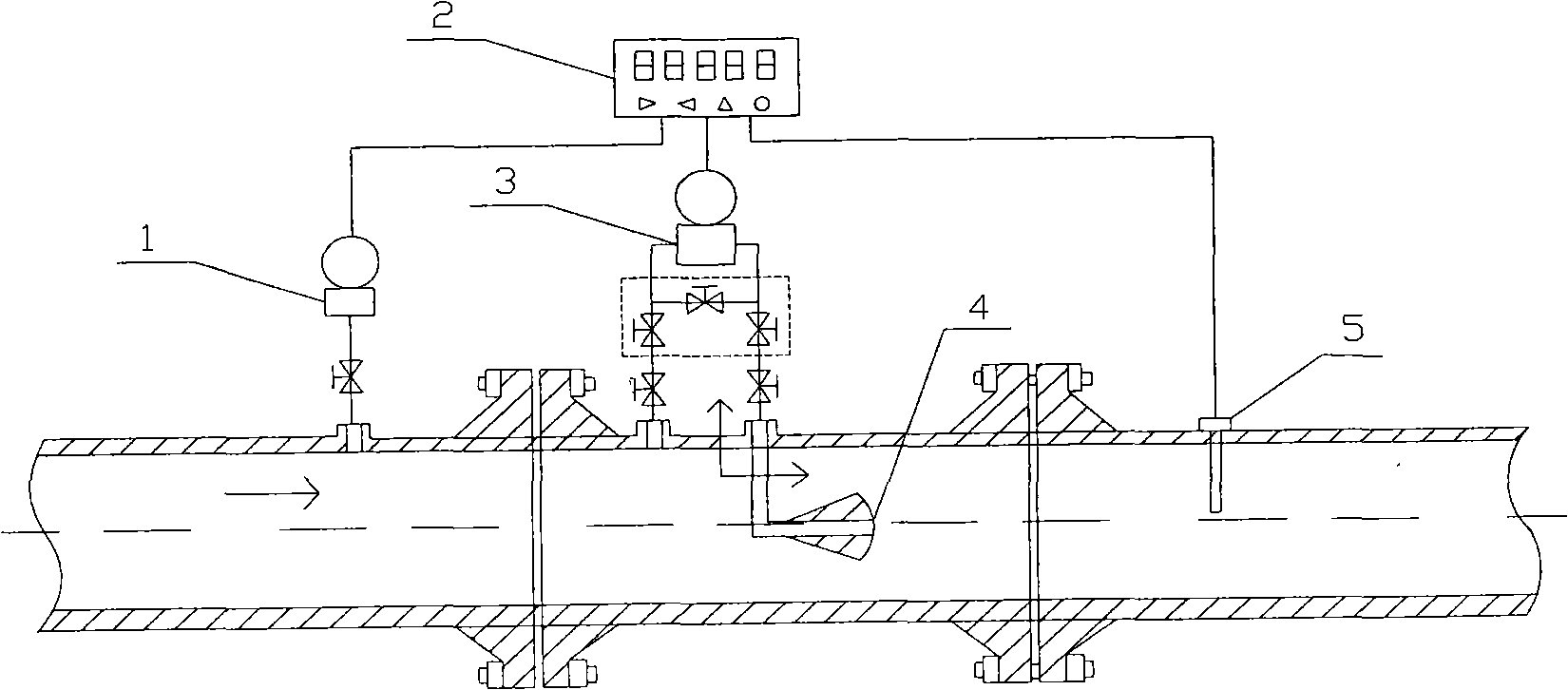

[0009] The heavy oil thermal recovery well saturated steam flow measurement method is realized by the heavy oil thermal recovery well saturated steam flowmeter. 3. V-shaped cone 4, composed of temperature sensor 5: pressure sensor 1 is threaded to the front section of the metering pipeline, display 2 is threaded to pressure sensor 1, differential pressure transmitter 3, and temperature sensor 5, and V-shaped cone 4 It is welded to the differential pressure transmitter 3; the V-shaped cone 4 is a new V-shaped inner cone structure, which determines the measurement range.

[0010] The method is to connect the saturated steam flow meter of the heavy oil thermal recovery well with the two ends of the manifold to the steam injection well. pressure to achieve accurate measurement of the flow rate of saturated steam. The differential pressure transmitter 3 is used to convert the flow rate into a flow signal and send it to the calculation system-display 2. The flow rate at this time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com