Horological movement with constant-torque transmission of power between the power source and the mechanical oscillator

A mechanical oscillation and energy source technology, applied to mechanically driven clocks, instruments, clocks, etc., can solve the problems of high cost and application complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

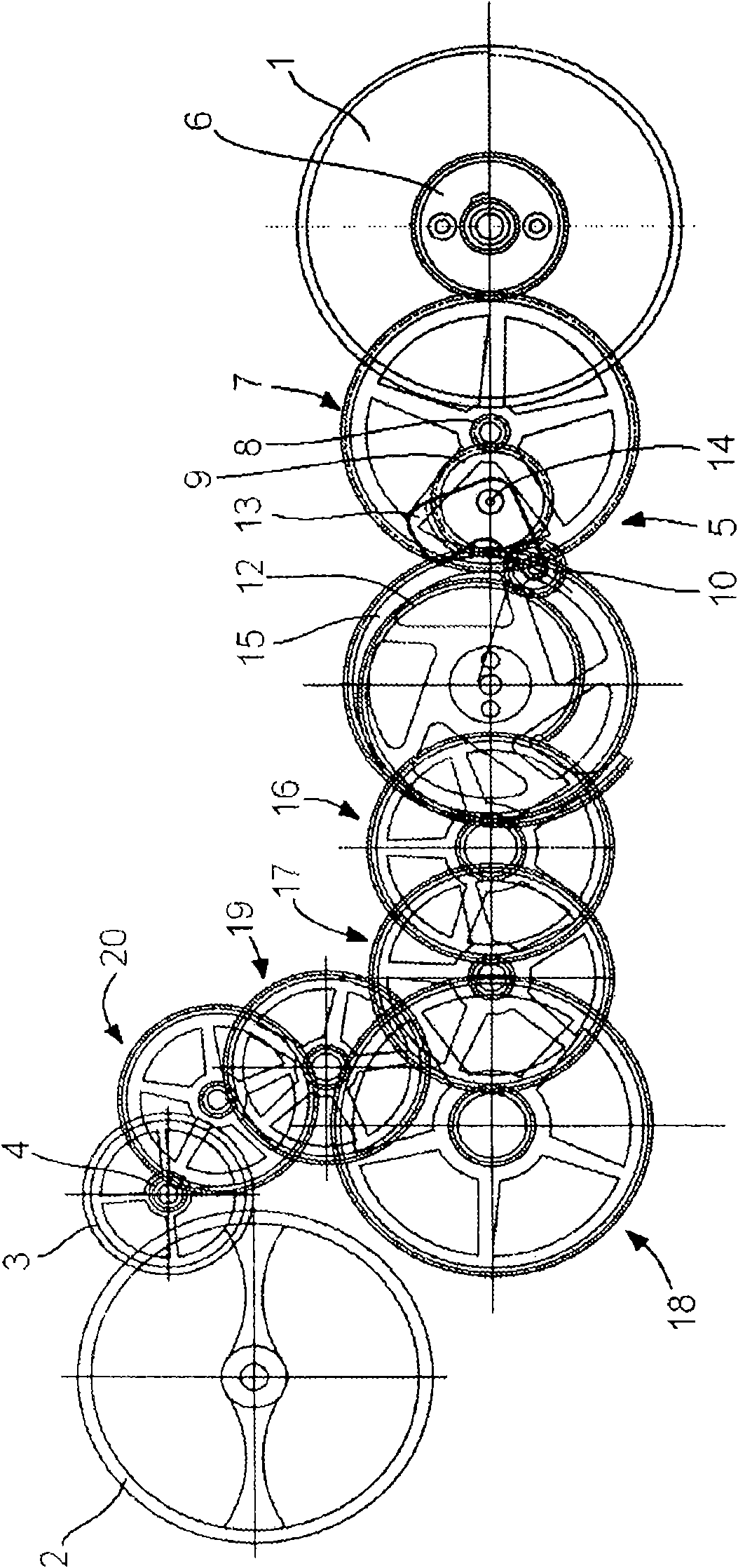

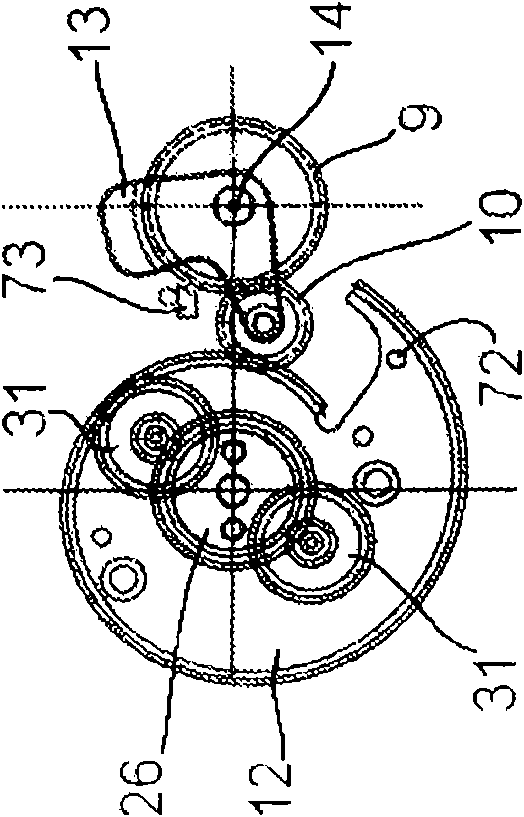

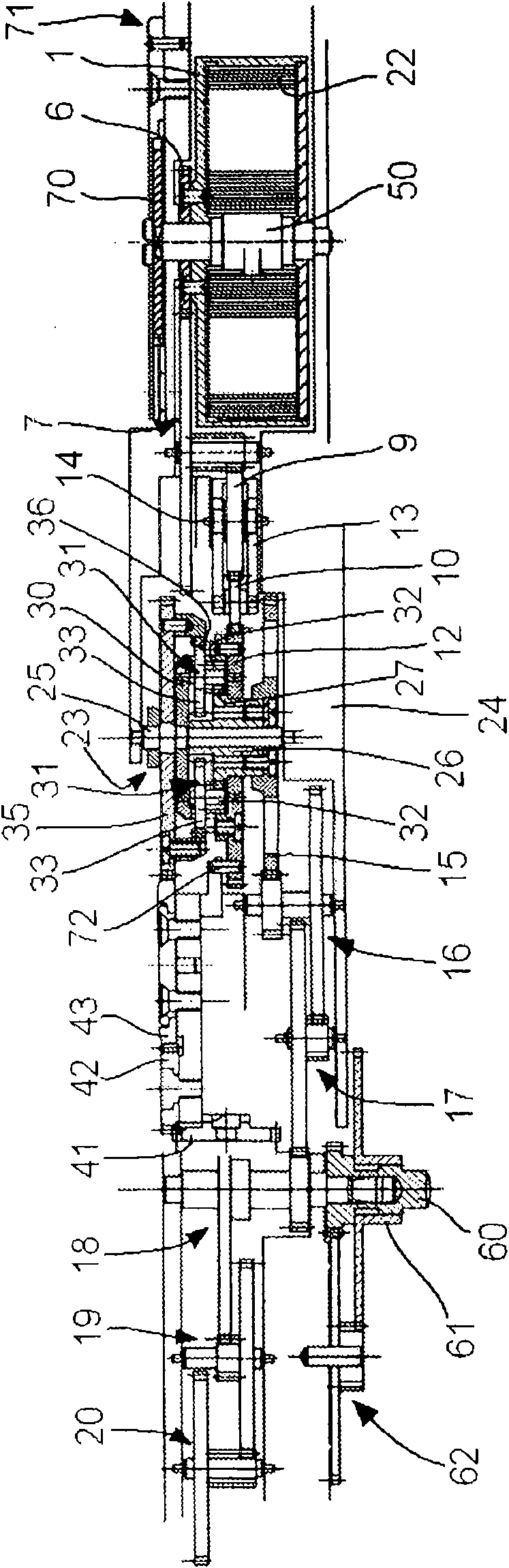

[0026] [26] In all figures, for reasons of clarity, only those parts useful for understanding the invention are shown.

[0027] [27] Figure 1a A simplified top view of a part of a clock movement with compensating means according to a first embodiment of the invention is shown. More precisely, only those parts are shown that play a role in the kinematic chain associated with the transfer of energy from the energy source to the mechanical oscillator whose oscillation is sustained due to this energy.

[0028] [28] Schematically, said energy source takes the form of a barrel 1 housing a spring (see Figure 2a ), said spring is used to maintain the oscillation of a balance wheel 2, in particular through a running train and an escapement, the wheel 3 and pinion 4 of which are only schematically shown.

[0029] [29] The mainspring is of a conventional type, the torque output of which is transmitted to the running wheel train is known to vary with its tension, which may jeopardize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com